8

DoorLIFT DL

-

6

Remote door system

4. Track installation

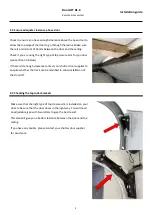

4.1 Positioning the rail on the roof

Mark the center line on the roof and measure

100mm sideways, as in the picture.

BE AWARE:

Check pre

-

installation requirements (page 4) for any reinforcements needed.

NOTE

: Depending on the roof/body structure the installer is required to decide on the type of fasteners and

amount of connections.

NOTE: Keep a space of 20

-

30 mm between the front of the

track and the balancer

20

-

30 mm

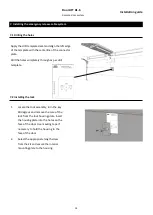

Place the left side (facing the door) of the

track allong the line. Keep a clearance

between balancer and track.

BE AWARE:

when the distance between track and balancer is too

much, it will hurt the operation of the system.

Installation guide