9

DoorLIFT DL

-

6

Remote door system

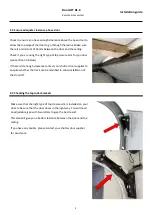

4.2 Fastening the rail to the roof

Use the groves in the track to DRILL the

required holes. The number of holes depends

on the roof structure. Minimum

requirements: front, back and middle of the

track. In case of dry freight applications,

always connect to every roof bow.

Insulated ceilings require furring strips or

some type of mounting brackets to secure the

track to the ceiling liner and roof. These

measures should of been accounted for in the

Pre Install Inquiry. DO NOT SECURE TRACK TO

THE CEILING LINER ONLY WITH NO SUPPORT.

Never glue the track to the ceiling

TIP

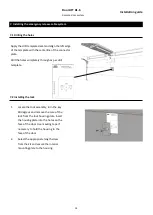

: Moving the motor unit back and forth in the track in this step and the next

makes lifting the track assembly easier. Move the lever, shown at the right, to

the manual position. The motor unit can now be moved by hand. Moving the

lever towards the battery icon will put the motor unit back in automatic mode.

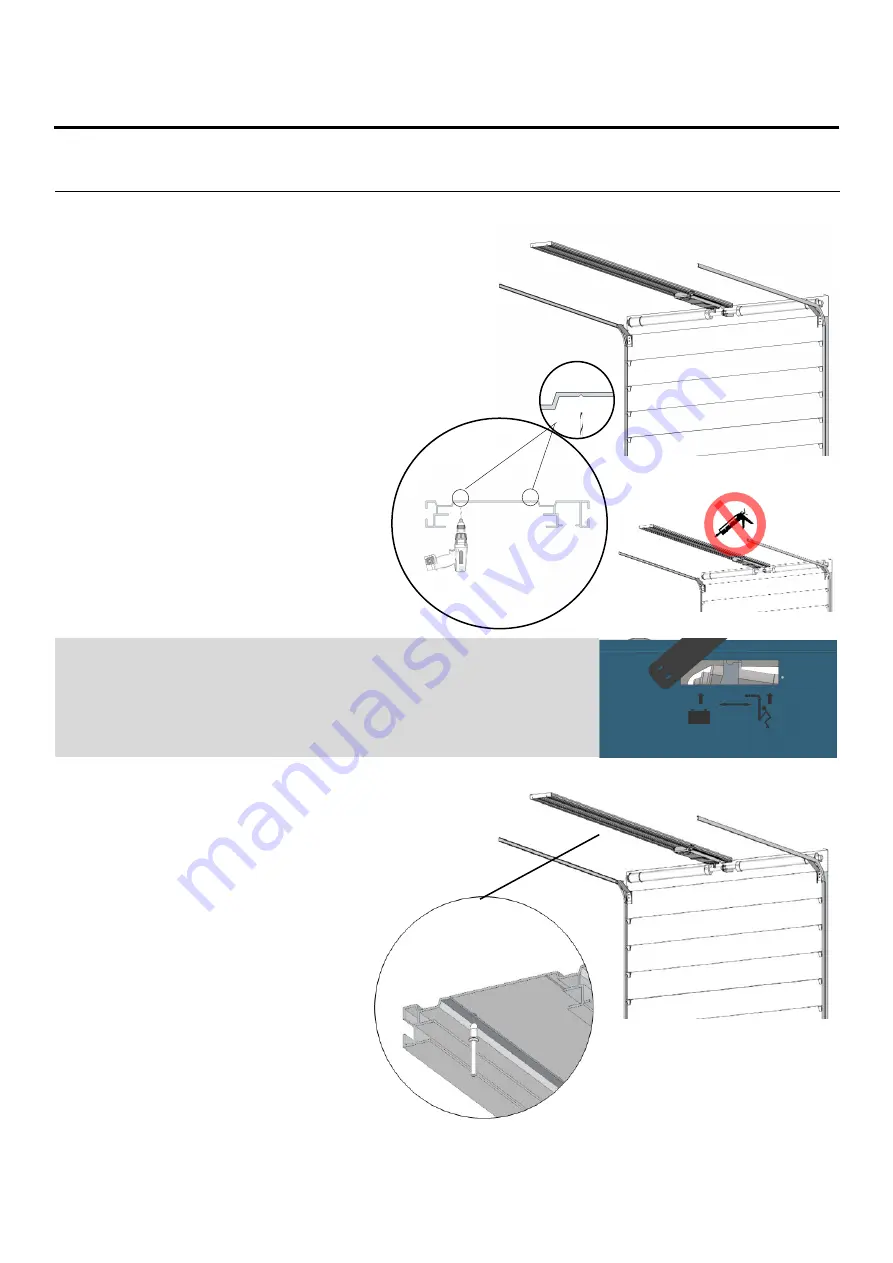

Use large diameter head screws or rivets

where the screw heads or rivet heads do not

protrude more than

1.8mm

from their seated

position. The motor unit will hit the

protruding screw or rivet heads during its

travel if the heads protrude more than

1.8mm

into its path of motion.

Secure the track to the roof. The number of

rivets is to be decided by the installer, as

every body is different. The aluminium profile

weighs approximately 14Kg and the motor

unit 7Kg.

* Important: Please drill and

install the fasteners using the

V

-

shaped guides on the track.

This will have motor clearance

implications if not followed.

Installation guide