ENGLISH (translation of original instructions)

EN

2.3 - t

echnIcal

specIfIcatIons

(*) The values refer to operation of the pump in bypass (maximum performance)

(**) CAUTION! Operation in bypass is allowed only for brief periods (1-2 minutes at most)

(***) The noise levels are measured at a distance of 1 metre from the electric pump in normal operating

conditions.

In order to maximise performance, pressure losses have to be minimised in the pump suction line as

follows:

- shorten the suction pipe as much as possible

- avoid, if possible, installing elbow fittings and/or throttling in the hydraulic circuit

- use a pipe with the same diameter or a diameter larger than the minimum specified in chapter 5 -

INSTALLATION

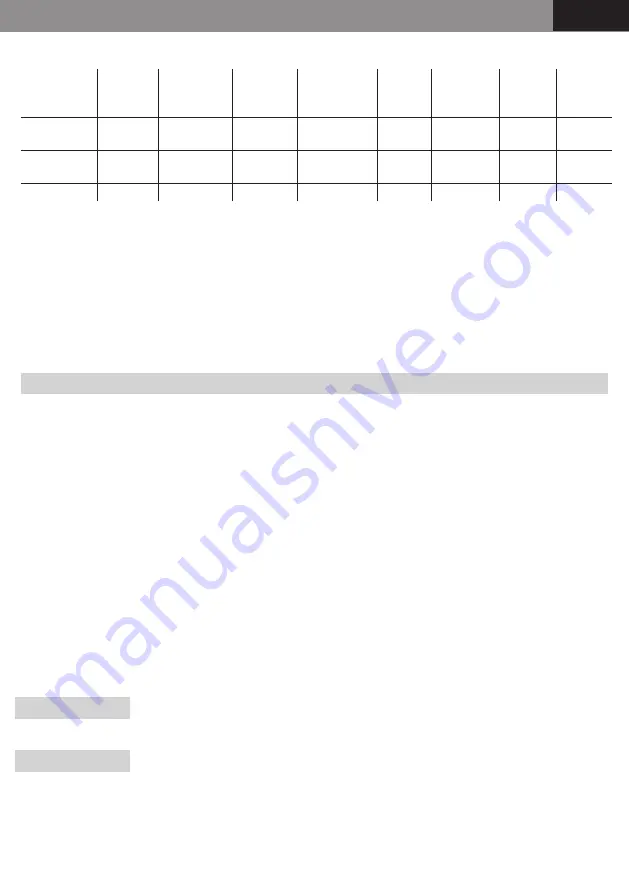

PUMP

MODEL

Power

supply

(*) Maximum

current

[Amp]

(*) Rated

power

[Watt]

(**) Work

cycle [min]

Max flow

rate [l/

min]:

Input/

Output

[BSP-G]:

(***)

Noise

[dBA]

Fuse (A):

E220

230V

50Hz

4

920

(S2) 30 min

30

3/4" - 3/4"

75

NO

E12-24

12V DC /

24V DC

18/28.5

216/684

(S2) 30 min /

(S2) 10 min

30/40

3/4" - 3/4"

75

30

E115

115V 60Hz

9.3

736

(S2) 30 min

35

3/4" - 3/4"

85

NO

3 - OPERATING CONDITIONS

3.1 e

nvIronmental

condItIons

3.2 - p

ower

supply

Temperature

Relative humidity

min. -20°C / max. +60°C (*)

max. 90%

(*) Caution! The temperature limits shown refer to the components making up the pump and should be

respected to prevent any damages or malfunctions from occurring.

Depending on the model, the pump must be powered by the single-phase AC line or by the DC line whose

values are given in the table in section 1.3 - Technical specifications.

Powering the pump with values outside these limits can damage the electrical components or cause them

to malfunction.

The maximum power supply variations allowed are:

Voltage +/- 5% of the nominal value

Frequency

+/- 2% of the nominal value

3.3 - a

llowed

fluIds

forbIdden

fluIds

Allowed

DIESEL FUEL AND OIL with 2 to 700 cSt viscosity (2 to 200 cSt for DC

versions) (at 38°C).

Minimum flash point (MF): 55 °C

Forbidden

PETROL

FLAMMABLE LIQUIDS (MF <55°C)

SOLVENTS

LIQUIDS WITH > 700 cSt VISCOSITY

FOOD LIQUIDS

CORROSIVE CHEMICALS

WATER