20

NMH0160 • 05.04.2013

ENGLISH

(underground!), pipes and steel reinforcement in the

work area. Do not use electric power tools in the pre-

sence of in

fl

ammable liquids/gases or in humid (rain)

conditions.

• Mount accessories and tools in the right way to pre-

vent them from coming loose. Check if all keys and

adjusting wrenches are removed from the machinery

before turning it on. Keep proper footing and balance

at all times.

MAIN COMPONENTS

The numbering of the illustrated product features refers to

the representation of the drill stand on page 4

1. Column

2. Lever

3. Handle

4. Carriage

5. Vacuumblock

6. Levelling

screw

7. Base

8. Vacuumrubber

9.

Drill-hole centre indicator

SPECIFIED CONDITIONS OF USE

The core drill rig is one out of a series of lightweight machi-

nes meant for drilling with diamond core drilling bits. The

machine can be used for drilling in concrete, asphalt en

stone-like materials. The function of the drill rig is to posi-

tion and guide the drill motor during the drilling process.

Do not use this product in any other way as stated for nor-

mal use.

WARNING! Under no circumstances may

the design of the machine be modi

fi

ed wit-

hout the permission of the manufacturer.

Always use genuine accessories. Non-aut-

horized modi

fi

cations and/or accessories

can result in serious personal injury or the death of the

operator or others.

WARNING! If the vacuum plate is used,

make sure the support surface is not po-

rous and can loosen from the

fl

oor or the

wall. Make sure that the vacuum pump has

suf

fi

cient power to secure the vacuum pla-

te. The vacuum plate must never be used for ceiling dril-

ling. Careless or incorrect use can result in serious,

even fatal injury.

SAFETY INSTRUCTIONS

Read all safety warnings and instructions

that were provided with the drill stand or

the drill. Failure to follow the safety warn-

ings and the instructions may result in

electric shock, fi re and/or serious injury.

Save all safety warnings and instructions for future

reference.

• Prevent dripping, leaking or unintentional uncoupling

of water hoses. Pay attention to the cooling water

during drilling overhead. Remove cooling water in a

safe way, for instance with a vacuum-cleaner. Keep

electric cables, plugs etc. dry.

• Watch what you are doing. Use common sense. Do

not operate machinery when you are tired or not con-

centrated. Make sure that you can always stop the

motor (emergency stop). Do not use the machinery

of which the ON/OFF switch does not work properly.

• Do not wear loose clothing or jewellery. They can

be caught in moving parts. When working in open

air rubber gloves and non-skid footwear are recom-

mended. Wear protective hair covering to contain

long hair.

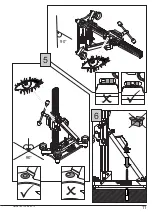

• Wear a helmet against falling parts, gloves for pro-

tection against sharp items and a safety goggle for

protection against sparks/small concrete particles.

Use a dust mask covering mouth and nose if nec-

essary. Ear protectors are recommended for sound

levels over 80 dB(A). For sound levels over 90 dB(A)

ear protectors are compulsory.

• Disconnect the plug from the power source before

making any adjustments or changing accessories.

Starting drills accidentally is the cause of some ac-

cidents.

•

Do not overload the drill rig and do not use it as a lad-

der or scaffold. Overloading or standing on the drill

rig can raise the drill rig’s centre of gravity and cause

it to tip over.

• Keep machinery tools sharp and clean for better and

safer performance. Follow maintenance instructions.

Keep handles dry and free from oil and grease.

• Check for alignment and binding of moving parts.

Breakage of parts and any other conditions that may

affect the normal use of the machinery. A guard or

parts that are damaged should be properly repaired

or replaced by an authorised service centre.

• The use of accessory and attachment other than

recommended in this manual or the catalogue may

present a risk of physical injury.

• Have your drill stand serviced/repaired only by a

quali

fi

ed repair person using original replacement

parts. This will ensure that the safety of the device

is maintained.

• Cluttered areas invite injuries. Do not let uninvited

persons or animals contact machinery or enter the

work area. Make provisions to catch loose concrete

parts/cooling water when drilling in storey

fl

oors or

roofs. When not in use, machinery must be stored in

a dry, locked-up place, out of the reach of children.

• Keep work area clean. Pay attention to all cables

Summary of Contents for 791500XS

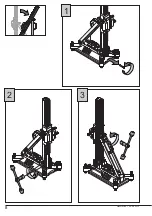

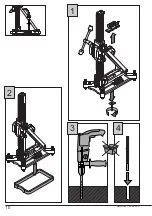

Page 3: ...3 NMH0160 05 04 2013 14 5 8 10 12 16 17 ...

Page 4: ...4 NMH0160 05 04 2013 1 5 2 3 4 6 7 8 9 ...

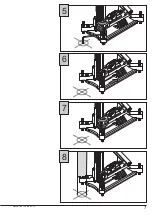

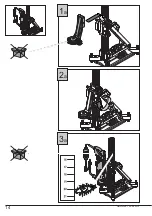

Page 5: ...5 NMH0160 05 04 2013 1 2 3 ...

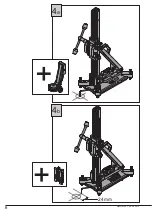

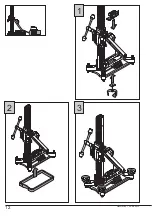

Page 6: ...6 NMH0160 05 04 2013 24 mm 4a 4b ...

Page 7: ...7 NMH0160 05 04 2013 5 6 7 8 ...

Page 8: ...8 NMH0160 05 04 2013 3 2 1 ...

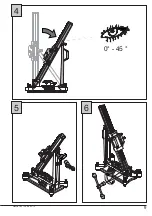

Page 9: ...9 NMH0160 05 04 2013 4 5 6 0 45 ...

Page 10: ...10 NMH0160 05 04 2013 1 2 3 4 ...

Page 11: ...11 NMH0160 05 04 2013 5 6 90 90 ...

Page 12: ...12 NMH0160 05 04 2013 1 2 3 ...

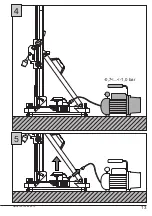

Page 13: ...13 NMH0160 05 04 2013 4 5 0 7 1 0 bar ...

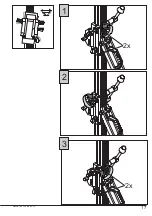

Page 14: ...14 NMH0160 05 04 2013 1a 2a 3a ...

Page 15: ...15 NMH0160 05 04 2013 1b 2b 3b ...

Page 16: ...16 NMH0160 05 04 2013 2 1 2 1 ...

Page 17: ...17 NMH0160 05 04 2013 2x 2x 1 2 3 ...

Page 30: ...30 NMH0160 05 04 2013 ...

Page 31: ...31 NMH0160 05 04 2013 ...

Page 32: ...AdamasB V Aartsdijkweg 19 2676 LE Maasdijk The Netherlands www adamas pro ...