CLEARPASS

Full-Body Security Screening System

OPERATION

MANUAL

Identification

ADN190.00.00.000 OM2

Revision

1

Date

02.2022

Page

37 of 52

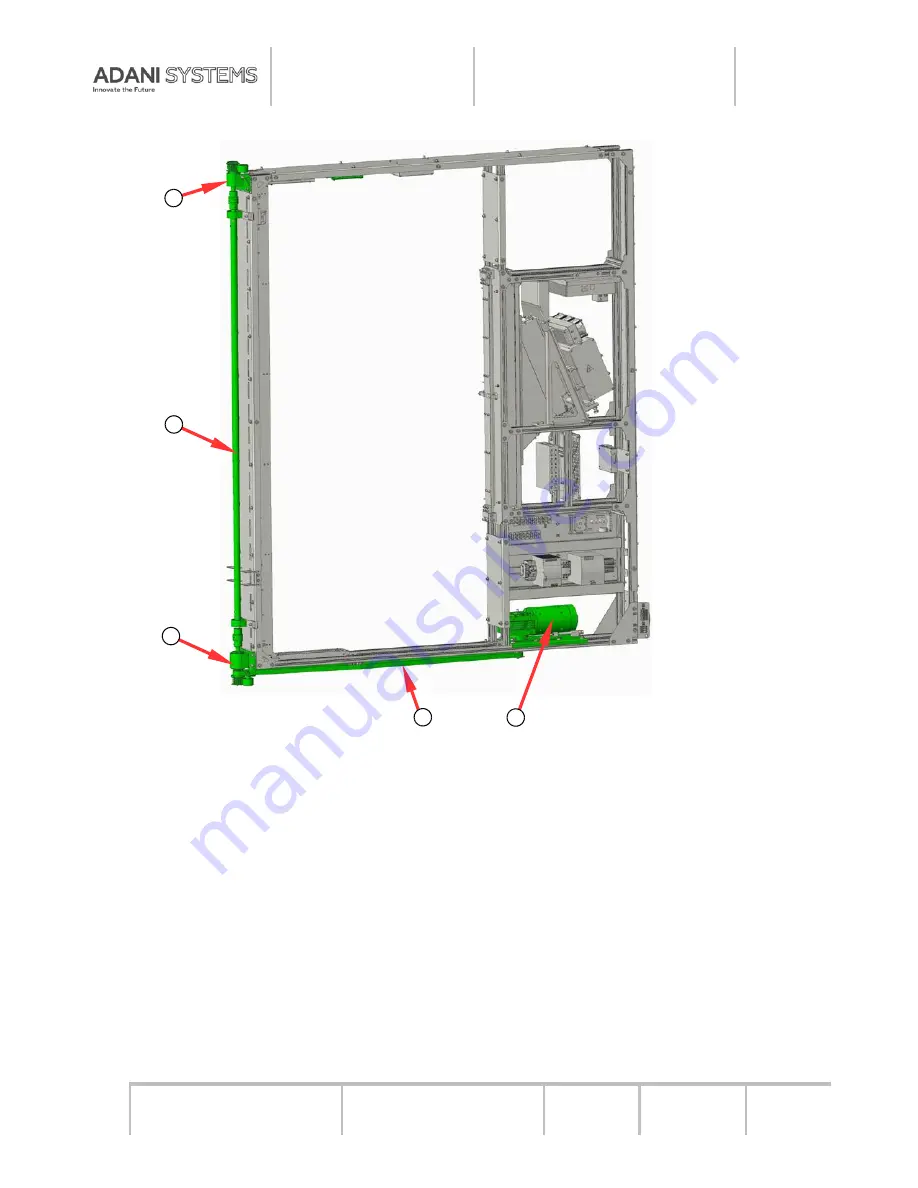

1 – The Upper Rotary Unit; 2 – Shaft; 3 – Lower Rotary Unit; 4 – Belt;

5 – The Electric Motor of The Rotary Mechanism.

Figure 3.10 – Rotary Mechanism

3.5 OPERATOR’S ACQUISITION/ANALYSIS WORKSTATION (OPERA-

TOR’S AWS)

Operator’s AWS is a software-hardware complex to control the System operation, to

acquire the full-height X-ray images of the inspected individuals, to view them and analyze.

The Operator’s AWS includes:

−

Operator’s computer from which the System control is performed;

−

Specialized software to ensure the System control;

3

2

1

4

5