2

1

10

7

6

8

9

13

5

4

11

14

12

3

2 of 5

SCALE 1:5

SCALE 1:6

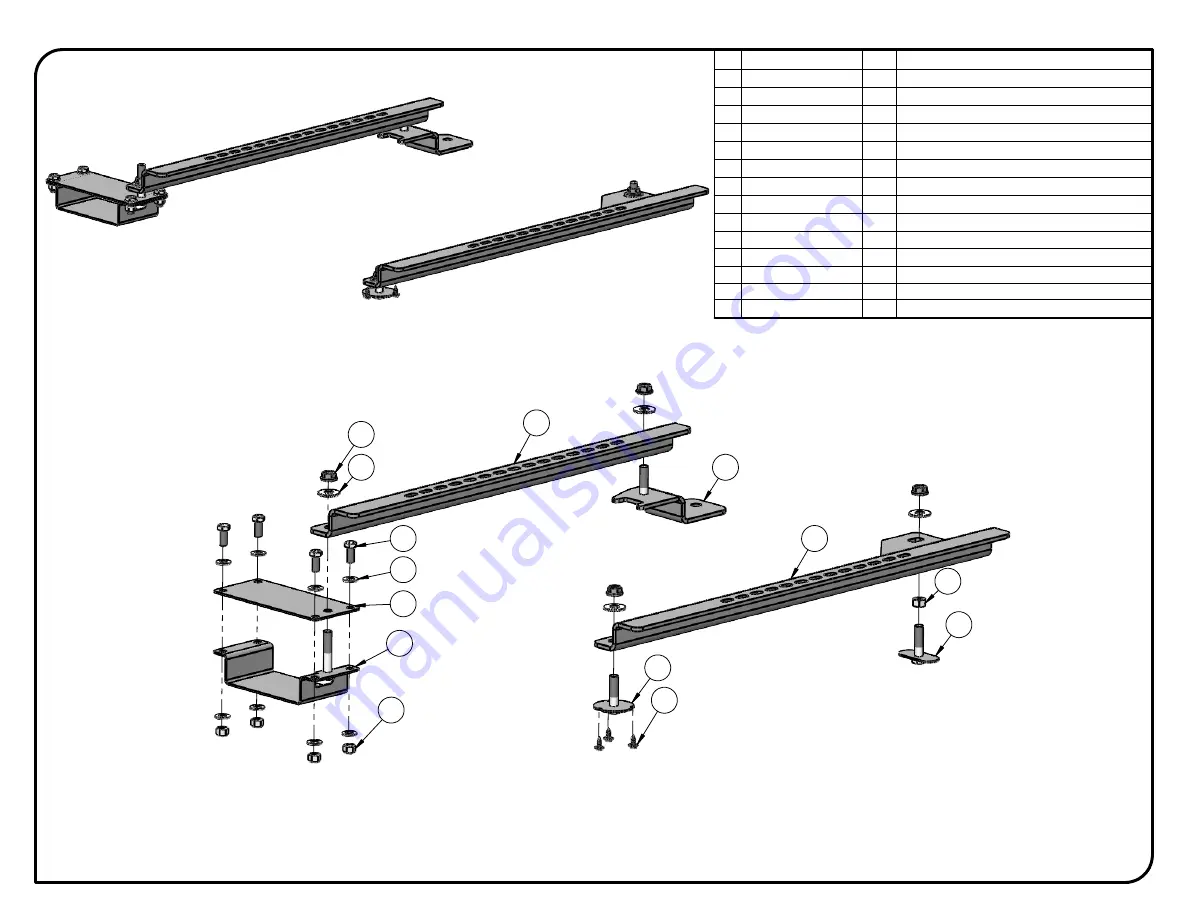

ITEM

PART NUMBER

QTY

DESCRIPTION

1

SL-CHR17L-01

1

Outside Floor Adapter -Left-

2

SL-CHR17-02

1

Inside Floor Adapter

3

SL-CHR17L-03

1

Rear Fixing -Left-

4

SL-CHR17-04

1

Front Fixing

5

SL-CHR17-05

1

Front Fixing

6

SL-CHR17-06

1

Front Fixing

7

SL-CHR17-07

1

Rear Fixing

8

PRD 110-104

3

Round washer head tapping screw #8 x 1/2

9

PRD 302-138P

4

Hex Cap Bolt Zinc Plated 5/16-18 x 3/4 G5

10

PRD 321-104P

1

Hex Nut Zinc Plated 3/8-16 G5

11

PRD 333-107

4

Nylon Insert Locknut 5/16-18

12

PRD 341-108P

4

Flat Washer Zinc Plated I.D. 3/8 USS

13

PRD 341-146P

8

Flat Washer Zinc Plated I.D. 11/32 SAE 5/16

14

PRD 2945

4

Flange Locknut Zinc Plated 3/8-16

SP-CHR17L

ADAPT SOLUTIONS

|tech@adaptsolutions.ca|866.641.0419|418.889.9838 fax

PART NUMBER

Speedy-Lift 2 Kit -Left-

DESCRIPTION

KIT SPEEDY-LIFT 2 CHRYSLER PACIFICA 2017+