USER’S MANUAL

V-line 899x.xxx/LPG HYBRID

29

4.7.

SOPA design

On Client’s special request the dispenser in service mode can be equipped with magnetic release switch

(SOPA design). The operator of the filling station can release the dispenser for single filling operation in

this mode. After nozzle lifting the displays are reset and fuel filling is started. After hanging up the

nozzle, the dispensed volume and quantity values are permanently displayed until the dispenser is

magnetic released and the dispensing nozzle is lifted off subsequently. The red signal light informs both

the operator and the customer about the condition of the dispenser.

4.8.

Design with heating of the electronic case

On the special customer´s requirement the fuel dispenser can be delivered with heating of electronic case

by heater 250 VA. For feeding of the heating is used an individual cable - see the enclosure no. 16.

5.

TECHNICAL DATA

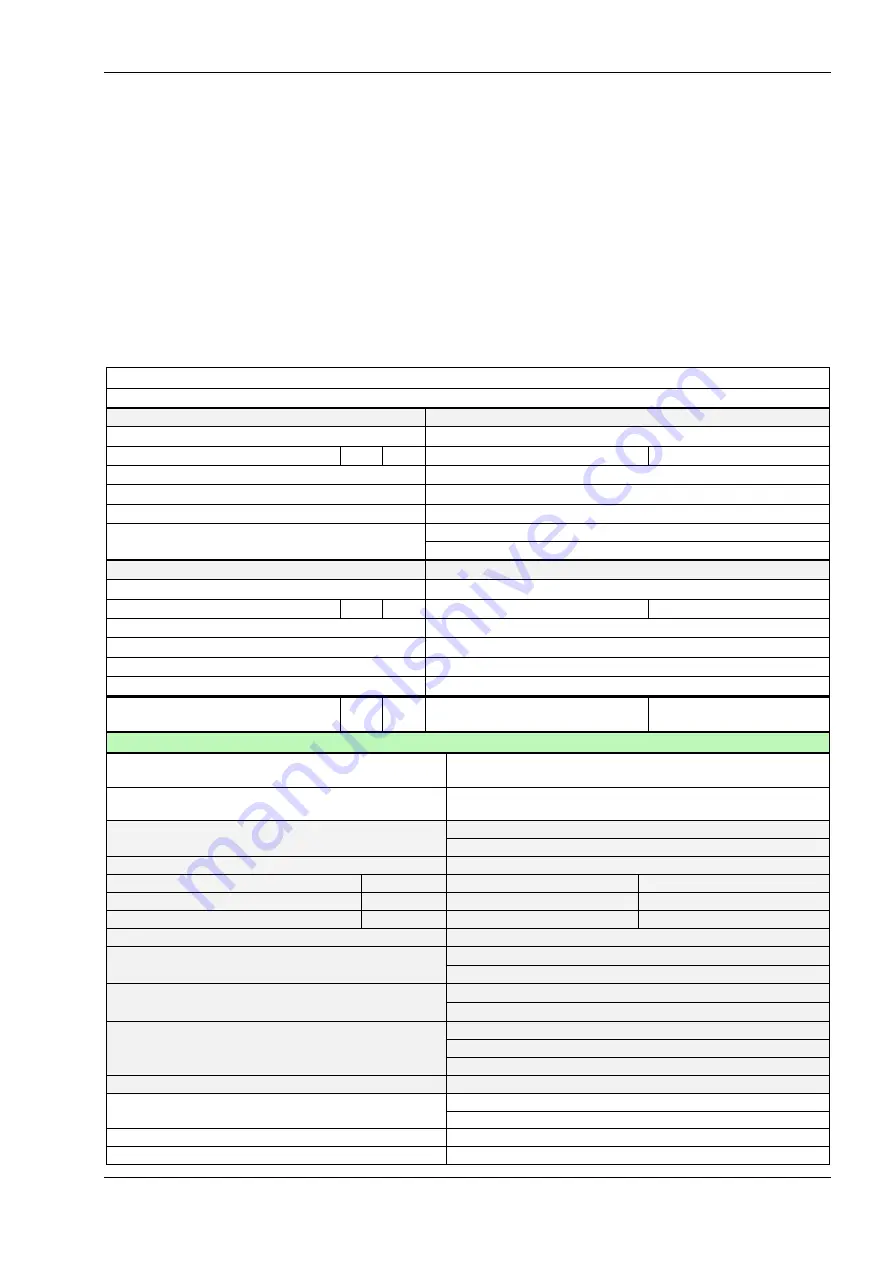

5.1. Basic parameters

Electronic counter

ADP1/T, ADP2/T

Display

Iluminated LCD - BACK LIGHT DISPLAY (BLD)

Power supply of electronics

U

nap

P

nap

1/N/PE AC 230 V ±15 %, 50 Hz

input 85 VA

Volume displayed

6 digits with the setting of digit position

Price displayed

6 digits with the setting of digit position

Unit price displayed

4 digits with the setting of digit position

Total volume counter

electromechanical - 7 digits

electronically - 11 digits

CDC

Display

Iluminated LCD - BACK LIGHT DISPLAY (BLD)

Napájení elektroniky

U

nap

P

nap

1/N/PE AC 230 V ±15 %, 50 Hz

Příkon 120 VA

Volume displayed

6 digits with the setting of digit position

Price displayed

6 digits with the setting of digit position

Unit price displayed

4 digits with the setting of digit position

Total volume counter

electromechanical - 7 digits

Power supply of electronic case

heating

U

nap

P

nap

1/N/PE AC 230 V ±15 %, 50 Hz

input 250 VA

5.1.1. Modul for petrol or diesel

Connecting flange of the suction piece – suction

system (S)

DN 40 with inner thread G 1 1/2―

pro Q = 40, 60, 70, 80 dm

3

.min

-1

Connecting piece – pressure system (P)

DN 40 with outer thread G 1 1/2―

pro Q = 40, 60, 70, 80 dm

3

.min

-1

Required inner diameter of suction piping – suction

system (S

)

DN 40 for flowrate Q = 40, 60 dm

3

.min

-1

DN 50 for flowrate Q = 70, 80 dm

3

.min

-1

Piping innner diameter required – pressure syst. (P)

DN 40 for flowrate Q = 40, 60, 70, 80 dm

3

.min

-1

Max. flowrate Q

max

1)

dm

3

.min

-1

40, 60

70, 80

Min. flowrate Q

min

1)

dm

3

.min

-1

4

5

Min. measured quantity (MMQ)

dm

3

2

5

Accuracy of measurement

± 0,5 %

Max. operating pressure p

max

Pro Q

max

= 40 – 60 dm

3

.min

-1

– 0,25 MPa

Pro Q

max

= 70 – 80 dm

3

.min

-1

– 0,32 MPa

Min. operating pressure p

min

Pro Q

max

= 40 – 60 dm

3

.min

-1

– 0,12 MPa

Pro Q

max

= 70 – 80 dm

3

.min

-1

– 0,19 MPa

Ambient operating temperature

Basic -20°C to +40°C

Standard -20°C to +50°C

Special -30°C to +60°C / -40°C to +60°C

Medium temperature

-20°C to +50°C

Filtering property

30 µm for petrol

30 µm for diesel (60 µm -

for extreme minus temperatures

)

Reach of dispensing hose

4 to 6 m

Max. level of noise

<70 dB