USER’S MANUAL

V-line 899x.xxx/LPG HYBRID

47

15.2.2.

Summary of principles for inspection of LPG Dispenser

To be carried out simultaneously with the inspection of the filling station gas equipment.

The inspection shall be performed only by an authorised body and consists of:

- inspection of the gas equipment

- repair of the gas equipment

The inspection of the process equipment, storage tank, piping and the LPG module is carried out in

periods specified in the operating regulations of the filling station according to the regulations in force

specifying intervals and scope of maintenance and inspection.

The following activities are carried out in the course of the inspection:

tightness test of the LPG module hydraulic system by means of a foaming agent

checking of the filter in the separator, cleaning or replacement

functional test of the non-return and safety valves

checking of the mechanical equipment, dust cleaning, elimination of water and other impurities from

storage tanks (LPG reservoir)

inspection, calibration and official certification of the LPG dispensing module are carried out

according to the regulation in force of the metrological office of the appropriate country

all identified defects are remedied after the inspection

Repairs of the filling station mechanical equipment are carried out after the identification of the faulty

condition symptoms and according to the conditions specified by the manufacturer of its individual parts.

The functional test and tightness test of the gas equipment are carried out after the completion of the

repair.

ATTENTION!

Service is performed by a service company authorised by the manufacturer!

16.

TRANSPORT

The customer shall agree to the method of dispenser transport from the manufacturer in the contract. In

case Adast Systems, a.s. provides the transport for the customer, the product will be delivered to the

agreed destination. The manufacturer possesses the necessary knowledge of handling and transportation

methods. In case the customer is responsible for another method of transport, the manufacturer shall

ensure professional loading of the product but is not responsible for the transport itself. It is generally

accepted that the dispenser shall be shipped properly boxed and always fixed to the wood pallete. The

dispenser should be protected against damage (of covering and painting), displacement and rolling over on

the means of transport. All manipulation and transport have to be carried out only in vertical position -

the dispenser must not be put on its covering.

ATTENTION!

Only forklifts are allowed to be used for manipulation. If other handling devices are used,

Adast Systems, a.s. does not guarantee any prospective damage!

17.

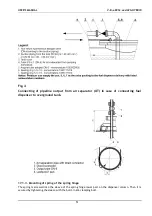

DISPENSER INSTALLATION

ATTENTION!

THE DISPENSER INSTALLATION CAN BE CARRY OUT ONLY BY THE ORGANISATION AUTHORISED BY

MANUFACTURER.

Read carefully the article

1. IMPORTANT NOTICE

.

The dispenser can be joined only to process equipment (tanks, piping) of perfect tightness and cleanness.

The supplier of the process equipment is responsible for its tightness and cleanness.

Prior to the installation the organisation shall perform the inspection of used power and communication

cables.