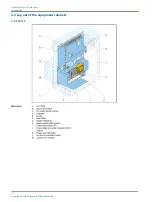

4.0 Commissioning

4.1 Main commissioning procedure

1. Remove the covers. See §

.

2. Configure the FCU PCBs. See §

3. Configure the flashing system. See §

4. Configure the remote control interfaces. See §

Remote control configuration: multiwire (option)

5. Install the covers.

6. Test the equipment. See §

4.2 Configure the FCU PCBs

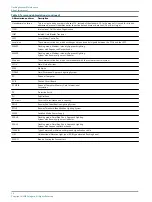

4.2.1 Set the communication parameters

Set the dip-switches dip-switch bank SW1 of each FCU PCB. This is the factory setting.

Note

Do not change the setting as indicated in the illustration. First contact ADB if you want change this setting.

4.2.2 Define the equipment address

Each FCU PCB in the system must have its own, unique binary address.

Note

If RTILS (REILS) are present:

•

Configure an unique address to both REILS or RTIL units;

•

Make sure the REILS or RTILS have the highest binary and physical address.

Physical equipment

order

Binary address

Physical equipment

order

Binary address

Physical equipment

order

Binary address

01

100000

09

100100

17

100010

02

010000

10

010100

18

010010

03

110000

11

110100

19

110010

04

001000

12

001100

20

001010

05

101000

13

101100

21

101010

UM-4019_AM02-620e, Rev. 3.0, 2020/05/12

19

Copyright

©

ADB Safegate, All Rights Reserved

Summary of Contents for FCU-1-in-1

Page 2: ......

Page 8: ...Flashing System Maintenance TABLE OF CONTENTS viii Copyright ADB Safegate All Rights Reserved ...

Page 18: ...Flashing System Maintenance Safety 8 Copyright ADB Safegate All Rights Reserved ...

Page 28: ...Flashing System Maintenance Introduction 18 Copyright ADB Safegate All Rights Reserved ...

Page 42: ...Flashing System Maintenance Commissioning 32 Copyright ADB Safegate All Rights Reserved ...

Page 64: ...Flashing System Maintenance Maintenance 54 Copyright ADB Safegate All Rights Reserved ...

Page 106: ...Flashing System Maintenance Technical data 96 Copyright ADB Safegate All Rights Reserved ...

Page 110: ......