12

American Dryer Corp.

112174-7

Electrical Information ________________

Electrical Requirements

All electrical connections must be made by a properly licensed

and competent electrician. This is to ensure that the electrical

installation is adequate and conforms to local and state

regulations or codes. In the absence of such codes, all

electrical connections, materials, and workmanship must

conform to the applicable requirements of the National

Electrical Code ANSI/NFPA NO. 70-LATEST EDITION or in

Canada, the Canadian Electrical Codes Parts 1 & 2 CSA

C22.1-1990 or LATEST EDITION.

IMPORTANT:

Failure to comply with these codes or

ordinances, and/or the requirements stipulated in this

manual can result in personal injury or component failure.

NOTE:

Component failure due to improper installation will

void the warranty.

Each pocket should be connected to an independently

protected branch circuit. The dryer must be connected with

copper wire only. Do not use aluminum wire, which could

cause a fire hazard. The copper conductor wire/cable must

be of proper ampacity and insulation in accordance with

electric codes for making all service connections.

NOTE:

The use of aluminum wire will void the warranty.

IMPORTANT:

A separate protected circuit must be

provided to each pocket.

NOTE:

An individual ground circuit must be provided to

each dryer, do not daisy chain.

IMPORTANT:

The dryer must be connected to the electric

supply shown on the data label. In the case of 208 VAC or

240 VAC, the supply voltage must match the electric

service specifications of the data label exactly.

The wire size must be properly sized to handle the related

current.

!

WARNING

208 VAC and 240 VAC are not the same. Any damage

done to dryer components due to improper voltage

connections will automatically void the warranty.

NOTE:

Component failure due to improper voltage

application will void the warranty.

The manufacturer reserves the right to make changes in

specifications at any time without notice or obligation.

Check your national and local code for breaker and wire size

8/18/14

Grounding

A ground (earth) connection must be provided and installed

in accordance with state and local codes. In the absence of

these codes, grounding must conform to applicable

requirements of the National Electrical Code ANSI/NFPA NO.

70-LATEST EDITION, or in Canada, the installation must

conform to applicable Canada Standards: Canadian Electrical

Codes Parts 1 & 2 CSA C22.1-1990 or LATEST EDITION.

The ground connection may be to a proven earth ground at

the location service panel.

For added personal safety, when possible, it is suggested

that a separate ground wire (size per local codes) be

connected from the ground connection of the dryer to a

grounded cold water pipe. Do not ground to a gas pipe or

hot water pipe. The grounded cold water pipe must have

metal-to-metal connection all the way to the electrical ground.

If there are any nonmetallic interruptions, such as, a meter,

pump, plastic, rubber, or other insulating connectors, they

must be jumped out with a wire (size per local codes) and

securely clamped to bare metal at both ends.

IMPORTANT:

For personal safety and proper operation,

the dryer must be grounded.

Provisions are made for ground connection in each dryer at

the electrical service connection area.

Electrical Connections

A wiring diagram is located inside the control box for

connection data.

If local codes permit, power to the dryer can be made by the

use of a flexible UL listed power cord/pigtail (wire size must

conform to rating of dryer), or the dryer can be hard wired

directly to the service breaker panel. In both cases, a strain

relief must be installed where the wiring enters the dryer.

Gas Models Only

IMPORTANT:

A separate protected circuit must be

provided to each pocket.

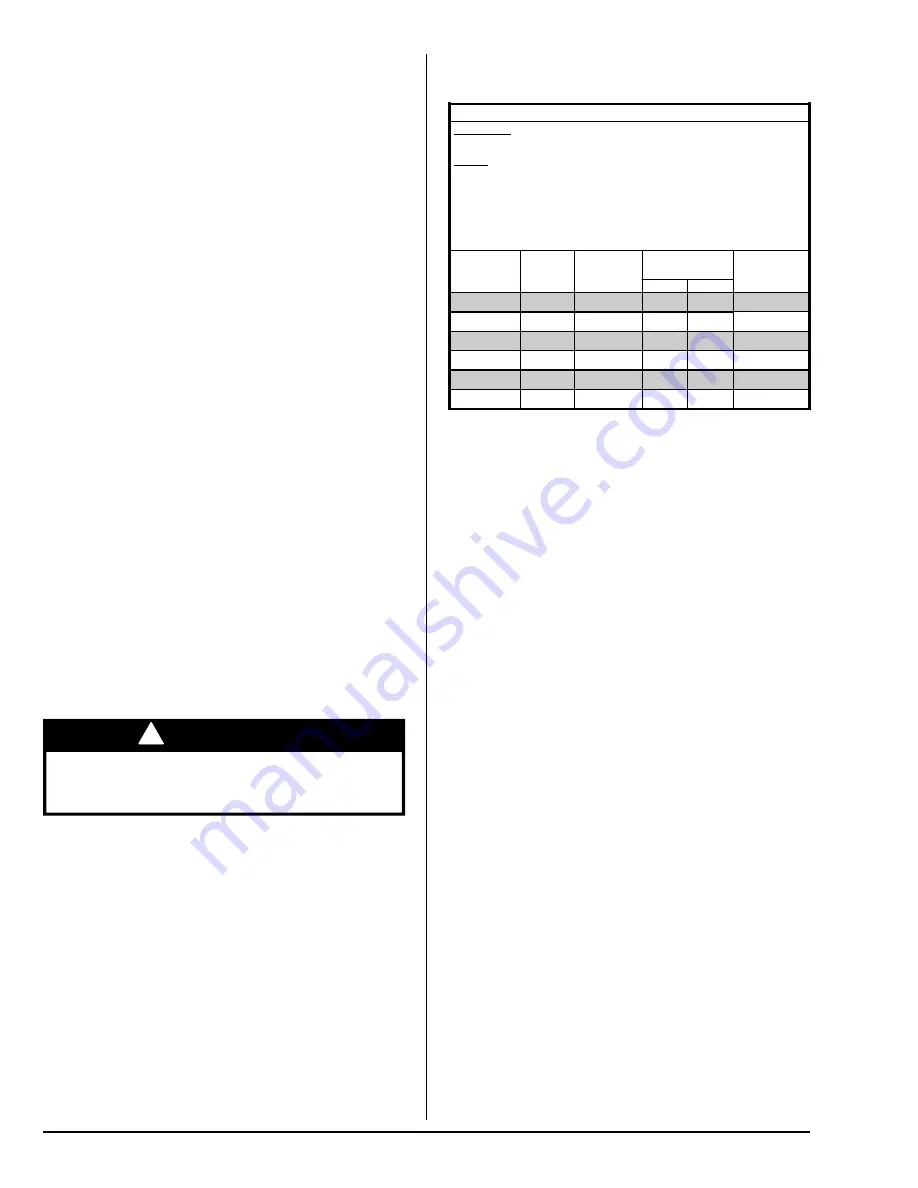

Electrical Service Specifications

Gas Models Only

ELECTRICAL SERVICE SPECIFICATIONS (PER POCKET)

IMPORTANT

:

NOTES

: A.

B.

C.

208 VAC AND 230/240 VAC ARE NOT THE SAME. When

ordering, specify exact voltage.

When fuses are used they must be dual element, time delay,

current limiting, class RK1 or RK5 ONLY. Calculate/determine

correct fuse value, by applying either local and/or National

Electrical Codes to listed appliance amp draw data.

Circuit breakers are thermal-magnetic (industrial) motor curve type

ONLY. For others, calculate/verify correct breaker size according

to appliance amp draw rating and type of breaker used.

Circuit breakers for 3-phase (3ø) dryers must be 3-pole type.

SERVICE

VOLTAGE

PHASE

WIRE

SERVICE

APPROX.

AMP DRAW

CIRCUIT

BREAKER

60 Hz

50 Hz

120

1ø

2

12

—

15

208

1ø

2

7

—

15

220

1ø

2

6.8

—

15

240

1ø

2

6.5

—

15

208

3ø

3

3

—

15

240

3ø

3

3.2

—

15

Summary of Contents for AD-444

Page 20: ...ADC Part No 112174 7 09 02 14 ...