7352 Series Digital Multimeter Operation Manual

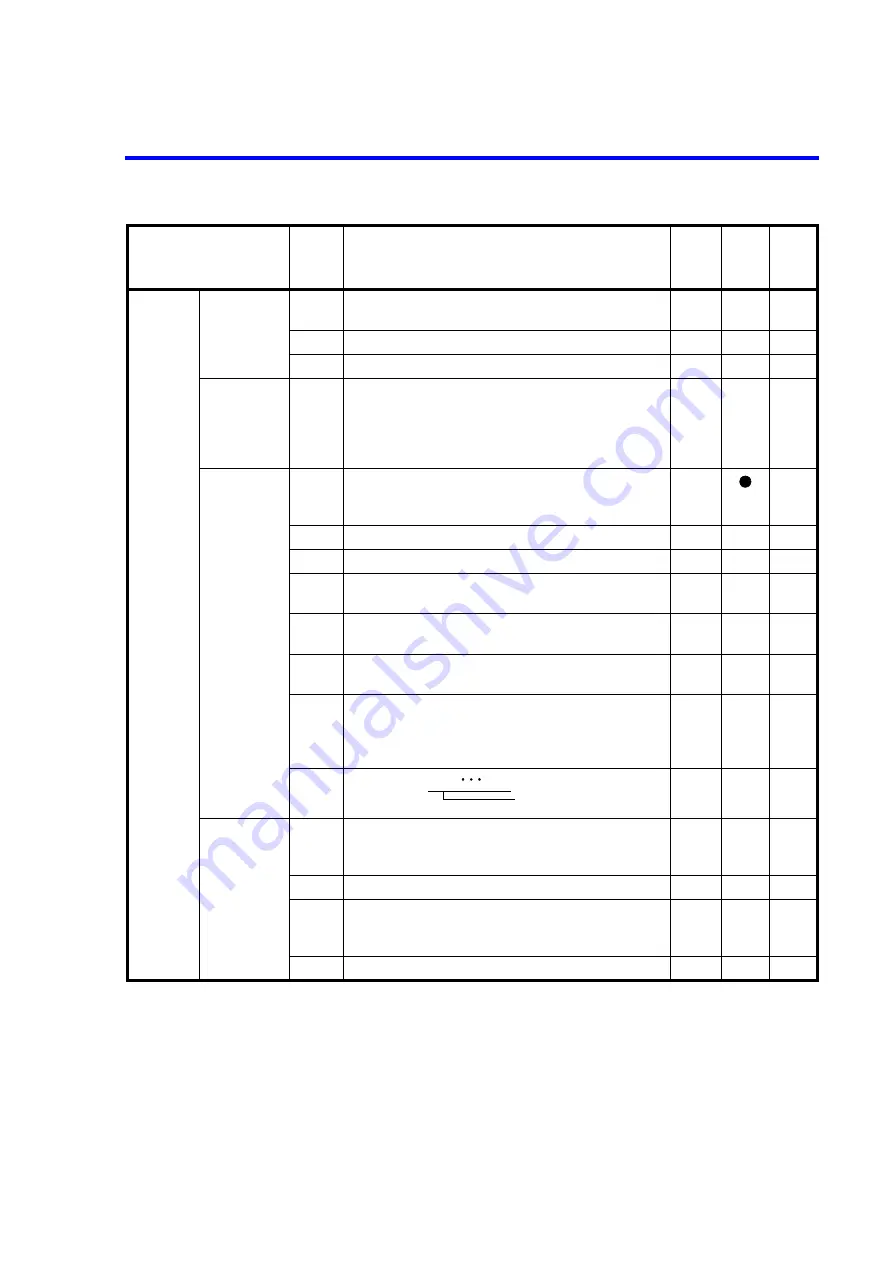

6.6.3 ADC Command Reference

6-29

System

Operation

complete

*OPC

Sets the operation complete bit (bit0) of the Standard Event

Status Register after all operations are complete.

–

*OPC? Reply: 1 (After all operations are complete.)

–

*WAI

Waits for the completion of all operations. (GPIB only)

–

Self-Test

*TST? Performs the self- test and reads the result.

(It takes time to perform the self-test. Read the result after

the *WAI command is executed.)

Reply 0 : Pass

1 : Fail

–

Calibration

CAL0 Sets the calibration mode to OFF.

(Writes the calibration factor when leaving the calibration

mode.)

–

CAL1 Sets the calibration mode to ON.

–

CAL?

Reply: CAL0 or CAL1

–

XOUT Cancels (sets to OFF) the calibration mode.

(Does not write the calibration factor.)

–

PCn

Enters the STD value. (Displayed count value)

n:0 to

999999

–

XDTn Enters the STD value. (Displayed value)

n: Displayed value on STD

–

CMNT

"str"

Sets the calibration information.

Enclose the character strings by using (") or (').

Up to 50 characters (one byte alphanumeric characters) can

be stored.

–

CMNT? Reply: CMNT"xxxx

xxx"

–

Setting

parameter

*SAVn

n:0 to 3

Saves the setting parameters in area [n] of the nonvolatile

memory.

–

SINI

Sets the values when shipping to all area from [0] to [3].

–

*RCLn

n:0 to 3

Loads the setting parameters from area [n] of the non-

volatile memory.

–

RINI

Loads the values when shipping as the setting parameters.

–

Item

Command

Description

Valid

command

for the 2nd

display

setting

Initial

value

R6452

Up to 50 characters