PA 358

Technical description Chapter 4

4

4 TECHNICAL

DATA

4.1 Electromagnetic

compatibility

The board has been subjected to EMC tests in an accredited laboratory in

accordance with the norms EN50082-2, EN55011, EN55022.

The board complies as follows with the limit values set by the norm EN50082-2:

True

value Set value

ESD ............................................................................ 4 kV

4 kV

Fields.......................................................................... 10 V/m

10 V/m

Burst ........................................................................... 4 kV

2 kV

Conducted radio interferences ................................... 10 V

10 V

Noise emissions ........................................................ B-class

WARNING!

The EMC tests have been carried out in a specific appliance

configuration. We guarantee these limit values

only

in this

configuration

4.2

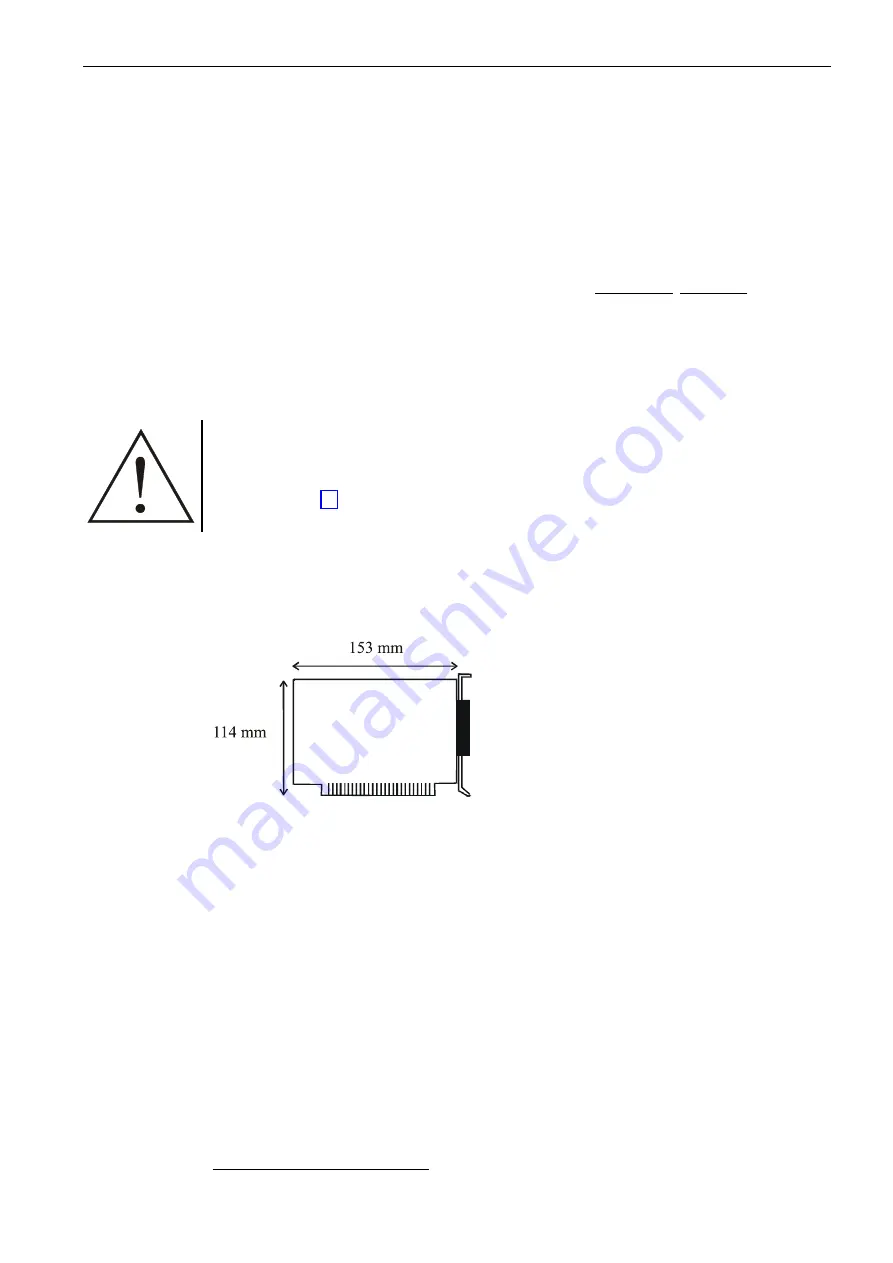

Physical set-up of the board

The board is assembled on a 4-layer printed circuit card.

Weight: 150

g

Installation in:

XT / AT slot

Connection to the peripheral through 37-pin SUB-D male connector

Standard cables:

ST010 or ST011

Screw terminal boards:

PX 901-AG, PX 901-A for

voltage

outputs

(PA

358-4/-6/-8)

PX

901-ZG

for

current

outputs

(PA

358-4C/-6C/-8C)

1) We transmit our appliance configuration on request.