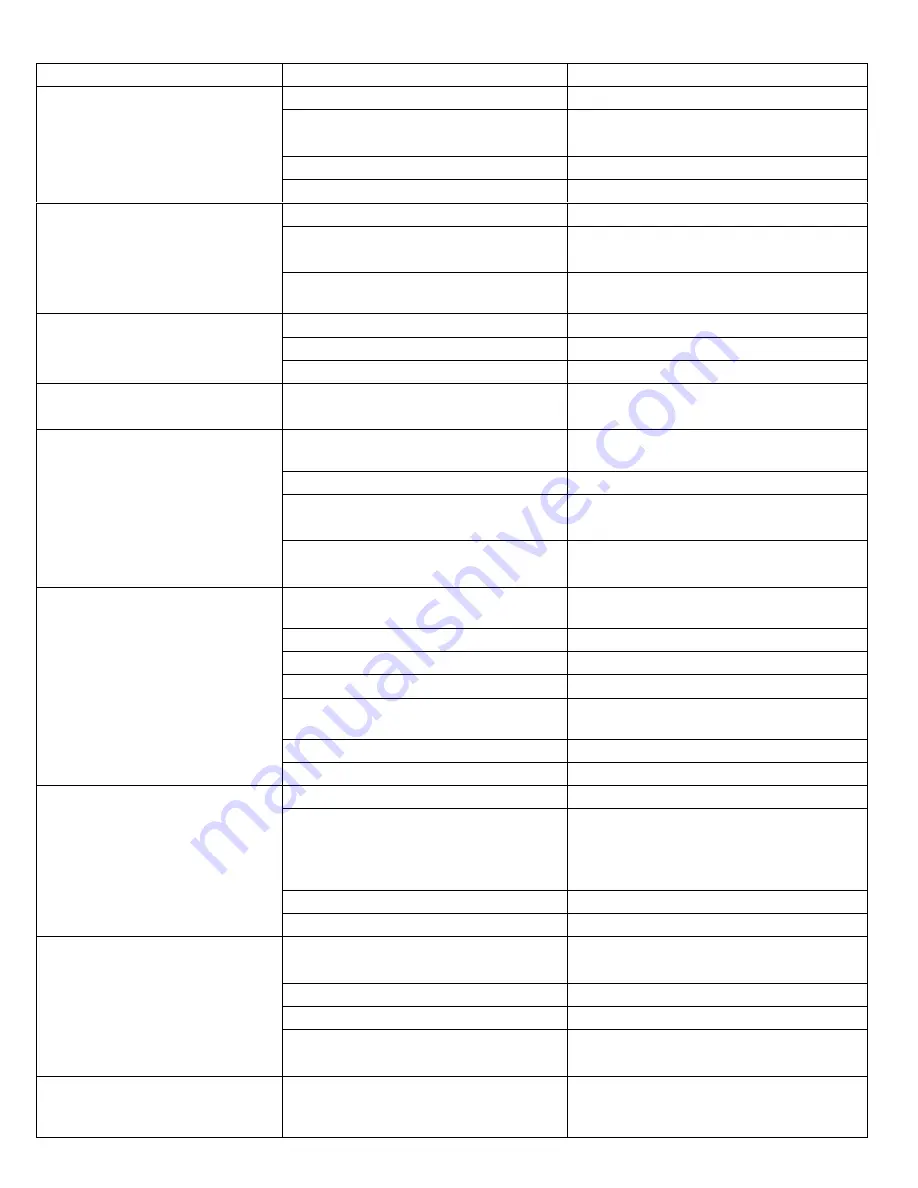

Troubleshooting

Problem

Possible Cause

Solution

No Display on PC Board

No power at electric outlet

Repair outlet or use working outlet

Control valve Power Adapter not

plugged into outlet

Plug Power Adapter into outlet

Defective Power adapter

Replace Power Adapter

Defective Circuit Board

Replace Power Head Assembly

Circuit Board does not display

correct time of day

Power Outage

Reset time of day

Power Adapter plugged into electric

outlet controlled by light switch

Use uninterrupted outlet

Tripped breaker switch and/or tripped

GFI

Reset breaker switch and/ or GFI switch

Control valve regenerates at

wrong time of day

Power Outage

Reset to correct time of day

Time of day not set correctly

Reset to correct time of day

Time of regeneration set incorrectly

Reset regeneration time

Time of day flashes on and off

Power Outage

Press any button to stop the time of day

from flashing

Unit does not regenerate

Electrical Service to unit is interrupted

Use uninterrupted outlet. Reset time of

day

Power failure

Reset time of day

Not Programmed

Enter Master Programming mode and

verify that the unit is configured properly

Defective Timer

Verify that days advance on main display.

If not replace Power Head Assembly

Unit does not draw air in "BD"

cycle

Injector is plugged

Clean or replace injector throat and

nozzle

Injector screen is plugged

Clean or replace injector screen

Line to drain is crimped or plugged

Replace drain line

Drain line flow control is plugged

Clean drain line flow control

Line pressure is too low

Increase line pressure to minimum of 20

psi

Internal control leak

Replace seals and spacers

Main drive gear grooved

Replace main drive gear

Water to drain continuously

Motor stopped or jammed

Replace motor if necessary

Foreign material in control

Remove power head assembly and

inspect bore. Remove foreign material

and check control in various regeneration

positions

Internal control leak

Replace seals and spacers

Main drive gear grooved

Replace main drive gear

Air in house line or at faucets

Iron Genie regenerating at same time

as other equipment is regenerating

Reset to correct time of day and verify

regeneration time of all equipment

Worn seals

Replace seals and spacers

Distributor O-ring damaged

Replace distributor O-ring

Inadequate water supply to meet

backwash requirements

Verify water supply and proper flow rate

Control cycles continuously

Misadjusted, broken, or shorted switch

Determine if switch or timer is faulty and

replace it, or replace complete power

head assembly

Summary of Contents for IRON GENIE1

Page 1: ...IRON GENIE Chemical Free Iron Sulfur Reduction...

Page 10: ...Power Head Assembly...

Page 12: ...CONTROL VALVE ASSEMBLY...