Nos. 11BR & 11WH

Nos. 11BR & 11WH

Nos. 11BR & 11WH

Nos. 11BR & 11WH

VIBRATION

SENSORS

INSTALLATION INSTRUCTIONS

INSTALLATION INSTRUCTIONS

INSTALLATION INSTRUCTIONS

INSTALLATION INSTRUCTIONS

11BR11WH-001-V0

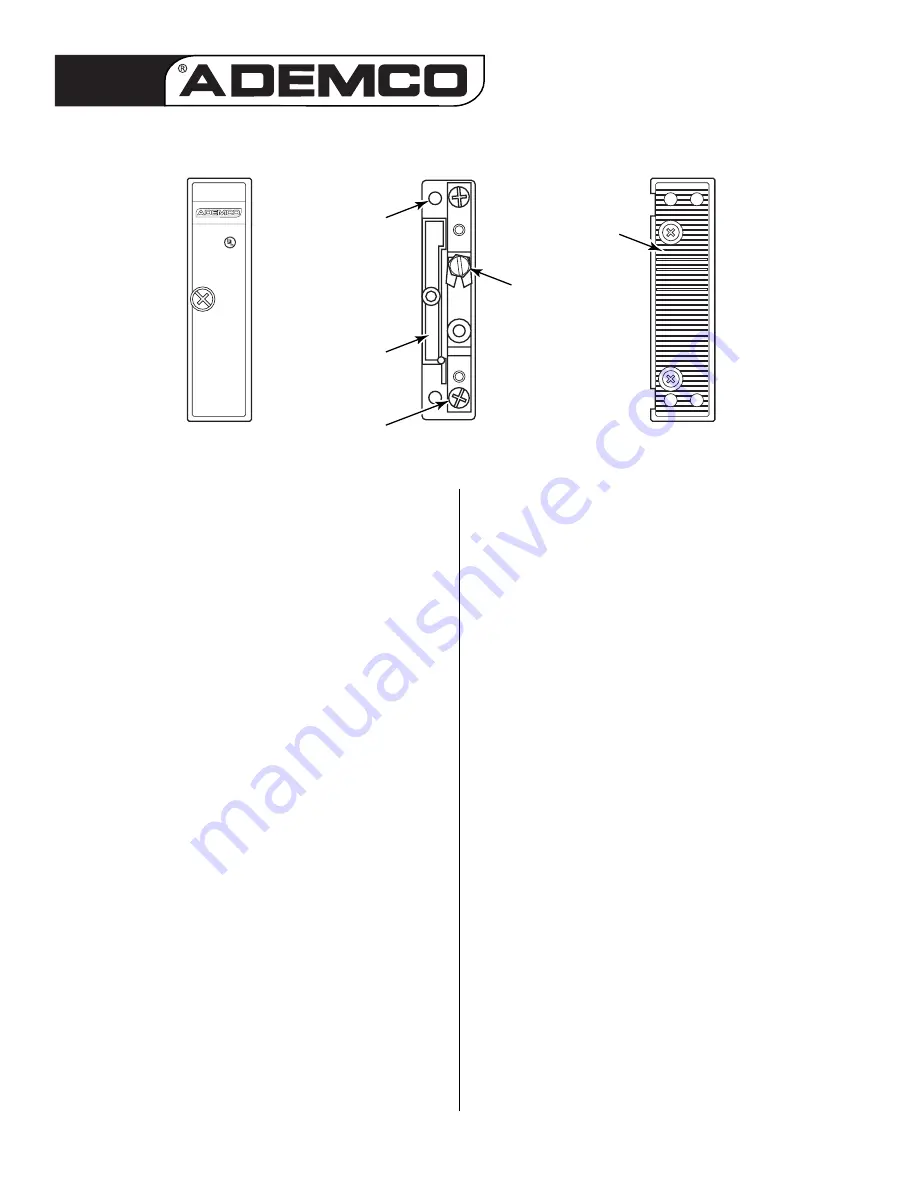

INTERIOR

REAR

COVER

TURN SCREW TO

ADJUST SENSITIVITY.

(CLOCKWISE TO

DECREASE).

STAY WITHIN RANGE

OF 1/8 TO 5/8 TURN

PAST POINT OF

INITIAL CONTACT

CLOSURE. SEE

ADJUSTMENT

PROCEDURE.

RIBBED REAR

SURFACE FOR

EASY CEMENTING

TO WALLS AND

WINDOWS

MOUNTING

HOLES (2)

ON VERTICAL

SURFACES,

MOUNT AS

SHOWN, WITH

WEIGHT

DOWNWARD

WIRING

TERMINALS (2)

No. 11 TYPE VIBRATION SENSOR

The No. 11BR (Brown Housing) and 11WH (White Housing) Vibration Sen-

sors are used indoors, in closed circuit alarm systems, to protect against

intrusion through windows, walls, ceilings, safes, cabinets, etc. The sensors

are UL Listed for use as supplemental protection (UL File AMQV:BP547).

INSTALLATION CONSIDERATIONS

Two holes are provided in the base for screw mounting The ribbed rear

surface of the base permits cementing to a glass, or other smooth, surface

if necessary.

When installing on a vertical surface, such as a wall, mount the sensor with

its long dimension vertical and its interior weighted blade downward, as

shown in the illustration.

On a ceiling, the sensor may be mounted directly thereon (upside down)

without the use of any bracket.

When protecting a window, mount the vibration sensor on the frame of the

window rather than directly on the glass. This reduces the danger of false

alarms from heavy vehicles passing by or from tapping on the window by

pedestrians.

When connected in a fast response (approximately 10ms) closed circuit

protection loop, vibration sensors will initiate an alarm when a blow of suf-

ficient force strikes the protection surface. The sensors can be adjusted to

respond on virtually any surface (e.g. plaster, sheet rock, plywood, cement

block, brick, glass).

Low frequency vibration caused by normal building vibration has little effect

on the sensor, as it is designed to respond much more efficiently to sharp

blows.

The sensor contacts are enclosed in an inner compartment that guards

against erratic operation in dusty or particle laden environments.

Temperatures ranging from -5° F (-21° C) to 150° F (66° C) had negligible

effect on the operation of the sensor in tests conducted by Underwriters

Laboratories.

The coverage of vibration sensors on walls and ceilings can be increased if

the contacts can be mounted on furring strips. On walls, run furring strips

vertically, from the ceiling to about 4 feet from the floor (the distance

between them is dependent on the type of construction). On ceilings, run

the furring strips from one end of the protected area to the other.

A typical installation for wall protection might consist of vibration sensors

mounted 42 to 48 inches above the floor and spaced at 36 to 48 inch

intervals along the wall. Optimum locations for vibration sensors can best

be determined by experimentation, because of the variety of construction

materials and methods that may be encountered.

ADJUSTMENT AND TESTING

An adjustment screw on the sensor's contact assembly permits sensitivity

adjustment with a screwdriver (see the illustration).

Initial Adjustment

Mount the sensor (leave the cover off). Connect an ohmmeter across the

sensor's terminals and slowly turn the adjustment screw. If the sensor

contacts are already closed, turn the screw counterclockwise until they

open. With the sensor contacts open, turn the screw slowly clockwise until

the contacts just close and continue turning exactly 1/8 turn (45 ) past the

closure point. This is the sensor's maximum advisable sensitivity setting.

Note:

Higher sensitivity (less than 1/8 turn past the closure point) is not

recommended, as erratic operation and raise alarms may result.

Final Adjustment

Connect the sensor in series with the closed protection circuit intended for

it. Light blows with a small hammer, approximately 2 to 3 feet from the

sensor, will permit its adjustment for desired response.

The sensor can be made less sensitive by turning its adjustment screw

clockwise. Turn it in 1/8 turn steps until the desired response is obtained.

Caution: Do not turn the screw more than 1/2 turn clockwise from the

maximum advisable sensitivity position described previously or

the sensor’s contact assembly vibration blade may be perman-

ently injured.

Replace the sensor's cover (do not overtighten!) and recheck the final

adjustment with the cover in place.

SPECIFICATIONS:

Length: 3” (76mm); Width 13/16” (21mm); Height 5/8” (16mm)

Contact Rating: 50mA @ 28VDC (max).

N4712 3/89