Selecting a Mounting Location:

The detector responds to changes in energy which occur when an intruder moves into

or out of a protective zone. Best coverage will be obtained if the mounting site is

selected such that the likely direction of intruder motion is ACROSS the pattern.

Passive I.R. units are remarkably resistant to false alarm hazards, but the following

recommendations should be observed:

Install the detector at a height of approximately 7 feet (2.1m)

from floor. Do not mount on an unstable surface.

IMPORTANT! Avoid running alarm wiring close to heavy-

duty electrical power cables.

Do not install where the detector is exposed to direct sunlight

or directly above strong sources of heat.

Avoid locating a unit in areas which contain objects likely to

produce a rapid change in temperature, such as central

heating, radiators or ducts (or heaters of any kind), air

conditioners, open flame, etc.

Make sure the detection area does not have obstructions

(curtains, screens, large pieces of furniture, plants, etc.)

which may block the pattern of coverage.

INSTALLATION

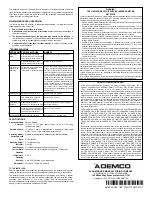

A. Changing From Wide Angle to Long Range Coverage:

1. Remove front cover by inserting a screwdriver blade in the groove between cover

and base at one of the locations shown in Diagram 3, rotating the blade to override

snap fit, and then lifting cover off.

2. Spread either or both plastic prongs holding the wide angle (12.2m) mirror and

remove the mirror (Diagram 4).

3. Insert one side of the long range (24.4m) mirror under a prong and snap the other

side under the other prong. Make sure that the mirror sides are squarely in their

corner rests and are held securely under the prongs.

NOTE: Mirror surface should be free of dirt, foreign matter and fingerprints. Use a clean

dry soft cloth to wipe mirror surfaces, if required.

LIFT

COVER

2

1

INSERT SCREWDRIVER

AT LOCATION a, b or c

AND TWIST

c

a

b

GENERAL INFORMATION

The No. 4278EX PIR is designed for use only with VISTA series systems equipped with

a 2-wire polling loop interface. The PIR provides wide angle coverage with a range of

up to 12.2m using the wide angle mirror, or long range/curtain coverage of up to 24.4m

using the long range/curtain mirror. The following important features are included in the

4278EX PIR:

• Quad element pyroelectric sensor providing the reliability of two completely separate

dual detectors covering the same area.

• High precision, computer designed parabolic optical system.

• Horizontally adjustable optical system for accurate aiming of protection pattern.

• Pulse count option.

• Low current drain which allows for direct powering from the multiplex polling loop.

• Wall/corner mounting plate.

• Walk-test LED with disable switch.

• Dual channel signal processing for enhanced immunity to environmental disturbances

(reduced false alarms).

• Two wire interface to control - power and signal on same wire pair.

• Auxiliary sensor loop permits interface of any other nearby alarm sensor (for example,

reed contact).

• 100% rejection of visible light interference.

• Tamper protected housing.

The detector is designed to operate at all times. The LED on the unit will be disabled

during normal operation to limit the power drawn from the polling loop.

PRINCIPLES OF OPERATION

The optical system divides the area into a series of protected zones. A quad element

sensor measures the level of infrared energy in each zone. When an intruder crosses

or enters any zone, a signal will be generated in response to the change in infrared

energy.

The detector is configured with an alternate polarity quad element sensor and two

independent signal processing amplifiers. In effect, two passive infrared sensors share

a common optical system. Both sensors must detect motions at the same time for the

PIR to report an alarm. In this way, immunity is provided against false alarms attributed

to channel noise, random detector disturbances, and power supply line transients, while

“catch” performance is not compromised.

COVERAGE CONSIDERATIONS AND TYPICAL LAYOUTS

The range will depend upon the mirror system in use. Protective patterns are shown in

Diagrams 1 and 2 for a normal mounting height of 2.1m. The unit may be mounted

higher for increased range but mounting above 2.6m is not recommended.

“Dead Zone” Caution: Note in Diagram 1 that a “dead zone” is indicated, within which

a person could be moving and not be detected by any of the unit’s protective zones.

Other dead zones may occur between the detector and the downward fields of view as

the unit’s mounting height is increased.

®

4278EX

PASSIVE INFRARED MOTION

DETECTOR

INSTALLATION INSTRUCTIONS

6.1m

3.0m

0

3.0m

6.1m

3.0m 6.1m 9.1m 12.2m

3.0m 6.1m 9.1m 12.2m

APPROX. 1.2m

DEAD ZONE

2.1m

0

DETECTOR

DOWNWARD

INTERMEDIATE

MAIN

TOP VIEW

SIDE VIEW

2.3m

3.0m 12.2m 24.4m

TOP VIEW

DIAGRAM 1. WIDE ANGLE PROTECTION PATTERN

DIAGRAM 2. LONG RANGE / CURTAIN MIRROR COVERAGE

0.7m 24.4m

SIDE VIEW

2.1m

See Diagram 4,

Note B.

INSERT SMALL SCREWDRIVER

TO RELEASE WALL PLATE

INTERLOCKING SPRING TAB

WIRING ENTRY

NOTCH (IN BOARD)

AND PASSAGE

(IN BASE)

PC BOARD

MOUNTING

TABS (2)

PC BOARD

SUPPORT

POSTS (2)

PLASTIC PRONG (2)

(HOLD MIRROR

IN PLACE)

HORIZONTAL

ADJUSTABLE

MIRROR

CARRIER

MIRROR WIDE ANGLE

MIRROR

CORNER

RESTS (4)

TERMINAL

BLOCK

LED

DIAGRAM 3. COVER REMOVAL

DIAGRAM 4. INTERIOR OF DETECTOR

MOUNTING SURFACE

HOOKS (2)

WIRE ENTRY AREA

SEE DETAIL "A"

SLOTS (4)

ENGAGE SLOTS

ONTO HOOKS

AND SLIDE

HOUSING BASE

DOWN FIRMLY

WALL

PLATE

EARS (4) FOR

CORNER

MOUNTING

(MAY BE

BROKEN OFF

IF MOUNTED

ON FLAT WALL)

CIRCUIT

BOARD

SUPPORT

POSTS (2)

CIRCUIT

BOARD

MOUNTING

TABS (2)

HOUSING

BASE

(COVER

REMOVED)

HOOKS (2)

C

L

IRCUIT

OARD

UPPORT

OSTS (2)

TABS (2)

FOR CONCEALED

WIRING, CUT A 8mm

DIAMETER (MAX) WIRING

HOLE IN MOUNTING

SURFACE. CENTER OF

HOLE MUST BE ON LINE

WITH TOP EDGE OF WALL

PLATE.

INTERLOCKING TAB ENTERS CUTOUT

IN BASE-LOCKS BASE TO PLATE

HOLE (3) FOR MOUNTING

THE PLATE TO WALL

DETAIL A

C

L

DIAGRAM 5. MOUNTING DETAILS

NOTES:

A. Thin exterior wal in wiring entry area can be

cut/broken away for surface wiring.

B. Hole along upper edge of housing permits use

of cover securing screw (required for

VDS/Skafor/ANPI compliance) and holes within

wiring entry area perit addition of wiring clamp.

Keep housing screw hole covered (with label

supplied or tape) if screw not used.

2.1m

APPROX

N4756-7ENV3 1/99

PART OF N4756-7V3