– 2 –

SETTING THE SITE ID

Some ADEMCO wireless devices (e.g., 5827, 5804BD) use a

programmed house ID to help avoid communication conflicts with

nearby installations. The 5800RP automatically passes all house

ID information to the appropriate receiver.

Certain newer ADEMCO wireless devices, such as the 5883 and

the 5839, use a “Site ID” instead of a House ID. The Site ID is a

factory-assigned, unique serial number built into each 5883

transceiver and must be entered into each device that uses it. The

Site ID provides many more combinations than a House ID, and

therefore is less likely to have conflicts with nearby installations.

When using the 5800RP with wireless devices that use a Site ID,

follow the steps below to enter a permanent copy of the Site ID in

the 5800RP. This procedure assumes that all such devices have

been successfully set-up and tested with the 5883, although they

may not yet be mounted in their final locations.

1.

Put the control (and the 5883) in the Go/No Go Test mode.

2.

Remove the 5800RP's cover by inserting and twisting a

screwdriver blade in the slot at the center of the cover's lower

edge. Note that removing the cover also places the 5800RP in

the Go/No Go Test mode. This decreases its range during

installation to insure an adequate margin during normal

operation.

3.

Temporarily disconnect the power supply and battery from

the 5800RP. Refer to Figure 2.

4.

Place DIP switch 1 in the ON position.

5.

Reconnect the power supply to the 5800RP. Observe that the

red LED on the 5800RP turns on and remains on. This

indicates that the 5800RP is ready to set the Site ID.

6.

Push and release the tamper switch on the 5800RP. This

causes a set-up request message to be sent to the 5883.

7.

Observe that the red LED turns off, indicating that the Site

ID has been saved in the 5800RP. If not, repeat the previous

step until it does.

NOTE: If the tamper switch is not pushed for 1 minute or if

DIP switch 1 is turned off, the red LED turns off. This

indicates the 5800RP will no longer accept the Site ID.

8.

Place DIP switch 1 in the OFF position.

9.

Replace the cover on the 5800RP.

10.

Take the control out of the Go/No Go Test mode.

11.

If needed locate the other wireless devices in their final

locations.

12.

Test all wireless devices.

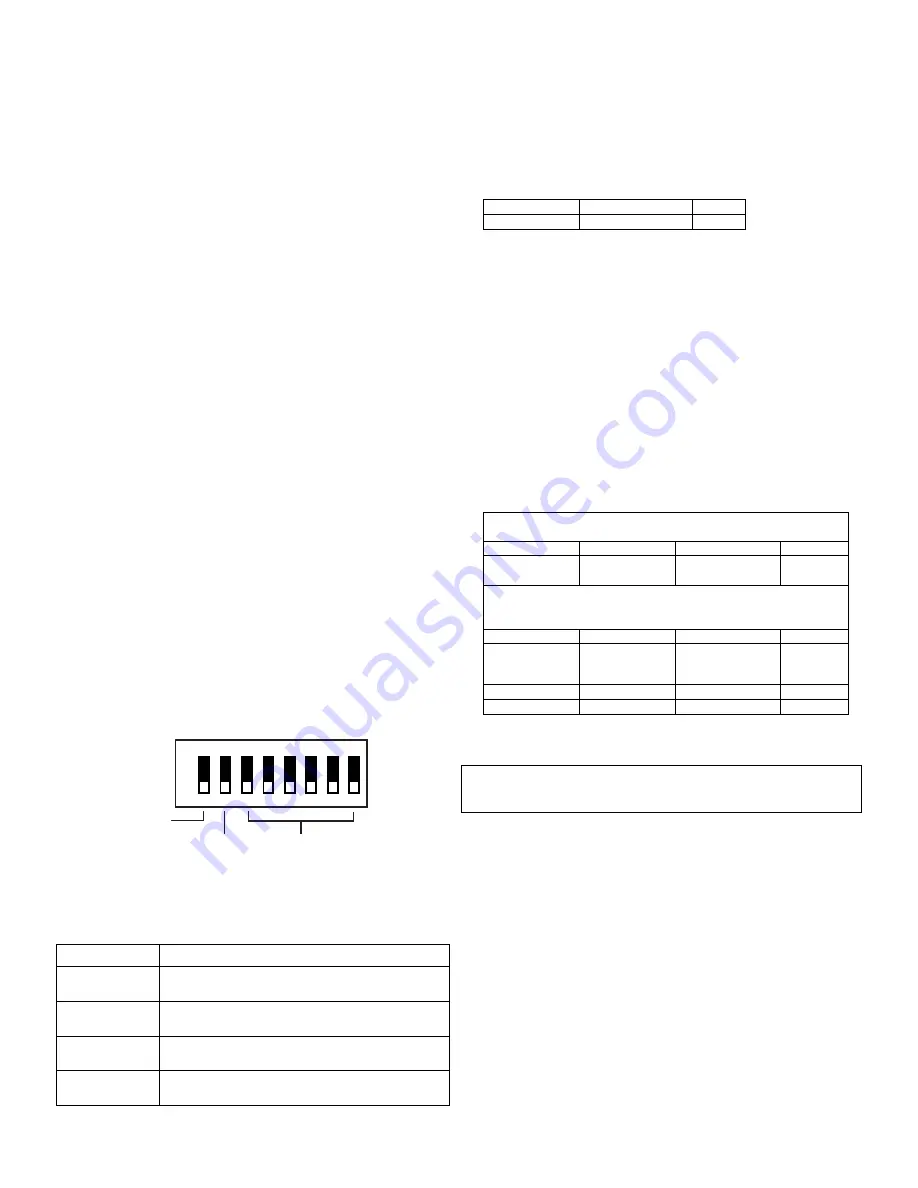

ON

2

3

4

5

6

7

8

1

MUST BE OFF

FOR NON - UL;

MUST BE ON

FOR UL

3 - 8

NOT USED

MUST BE OFF

SW-1

USED WHEN

ENROLLING

SITE ID;

OTHERWISE

MUST BE OFF

5800RP_dip-00-002-V0

Figure 3 5800RP DIP Switch

LED FUNCTIONS

LED

Activates Upon

Green

Normally on (lighted) when power (AC or battery) is

present. Flickering indicates RF is being processed.

Yellow

Normally off. Blinks to indicate that an RF

message is being sent by the 5800RP.

Red

Normally off. Turns on (lighted) when setting Site

ID. See the Setting the Site ID section for details.

Red

RF Interference

Lights when RF activity is present.

PROGRAMMING AND OPERATIONAL NOTES

Non-UL Installations

(DIP switch 2 must be OFF during normal operation)

1. Set DIP switch 2 to OFF.

2. If module supervision is desired, assign the 5800RP to a zone for

sending check-in, low battery

†

, AC loss, and RF jam messages,

and enroll its serial number. When prompted, toggle the tamper

switch to enroll the serial number. The yellow LED should blink

on when messages are sent.

Program the zone as follows:

Zone Type

Input Type

Loop

8

(24-hour aux)

3

(supervised RF)

1

•

The 5800RP reports AC loss and RF jam conditions as “low

battery” status, which is also displayed on the control’s keypads.

This prevents either condition from causing an alarm when the

control is armed.

•

The 5800RP will not repeat a message that has already been

repeated.

UL Installations

(DIP switch 2 must be ON during normal operation)

1. Supervision: Module supervision is required using the module’s

built-in serial numbers, which are enrolled in 4 zones as follows:

– Assign the first serial number to a zone for sending low

battery

†

and supervision check-in messages.

– Assign the second serial number to 3 zones for sending

tamper, AC loss, and RF jam messages.

When prompted, toggle the tamper switch to enroll the serial

numbers.

Program the zones as follows:

First Serial Number

Set DIP switch 2 to OFF, then enroll as follows:

Zone

Zone Type

Input Type

Loop

Low Battery/

Check-in Zone

8

(24-hour aux)

3 - RF

(supervised RF)

1

Second Serial Number

Set DIP switch 2 to ON, then enroll as follows:

(keep switch 2 in the ON position when enrolling is complete)

Zone

Zone Type

Input Type

Loop

Tamper Zone

5

(trouble by day /

alarm by night)

4 - UR

(unsupervised RF)

1

AC Loss Zone

8

(24-hour aux)

4

- UR

2

RF Jam Zone

8

(24-hour aux)

4 - UR

3

For easy identification of these messages, program alpha

descriptors at the control for each zone, using words such as

“REPEATER LOW BATTERY, REPEATER AC LOSS, etc.

† If an actual low battery condition is reported, it takes up to 12

hours after AC power is restored for the low battery restore

message to be sent (requires 12 hours for fully recharged battery).

2. Power Supply: Use a class 2 Listed Burglar Alarm power

supply for UL installations.

3. Control Panel’s Current Drain Calculation: In order to

properly choose the correct backup battery capacity for systems

using a 5800RP in UL installations, use the connected keypad’s

maximum alarm (sounder on) current rating, not the keypad’s

standby current rating, when calculating the control panel’s

total current drain. This is necessary because AC loss at the

5800RP causes the keypad to beep.

SPECIFICATIONS

Dimensions:

7-3/8" W x 4-3/8"

(10-7/8” w/antennas)

H x 1-7/16" D.

188mm W x 112mm H

(277mm w/antennas)

x 37mm D.

Input Voltage: 12VDC or 9VAC, 15VA (from separate power

supply such as ADEMCO 1332).

Current:

80mA

Battery Pack: rechargeable, part number K0257

Range:

200ft (60m) nominal indoors from wireless devices

(the actual range to be determined with the

security system in the TEST mode).

www.PDF-Zoo.com