Page 2

Serial No. ID

This unit does not utilize DIP switches to set its zone number (ID). Each

unit has a unique factory-assigned serial number which must be

"learned" by the control panel during the zone programming procedure.

Therefore, this PIR can be used only with a control panel that supports

serial number devices.

Note that this PIR's unique factory-assigned serial number can be found

on the bar code label on the left-hand corner of the PC board.

The PIR's serial number can be entered by one of the following

methods:

1. Downloading (Zone Definition screen of V-Link software). Recom-

mended for large installations and installations where foot traffic can-

not be controlled.

2. Entered in manually at the "learn" prompt during manual zone pro-

gramming (see

Important below).

3. "Learned" by faulting the detector twice while at the "learn" prompt dur-

ing manual zone programming.

If programmed manually, be sure that other polling loop sensors are not

activated so that they cannot send a signal to the control while this PIR

is being programmed (mask PIRs, don't open/close doors, etc.).

IMPORTANT: To be sure that other polling loop devices are not activated

when entering serial numbers manually, power the system down,

disconnect the polling loop at the control, power back up again, and

immediately enter the program mode. Then proceed to Step 1 (below).

Remember to reconnect the polling loop when programming is com-

plete, powering the system down first.

To either manually enter or "learn" the unit's serial number:

1. Enter *93 Zone Programming mode.

2. Enter the Response Type and other zone information for the PIR, press-

ing [*] to advance from prompt to prompt.

3. At the "Input Type" prompt, enter "6" for SL (Serial Polling Device) and

press [*].

4. At the "Learn S/N?" prompt, enter (Y)es.

5. At the "Input S/N" prompt, either enter the serial number manually (and

a "1" for the loop number), or fault the PIR being learned (the keypad

will "beep" to confirm signal). Wait three to six seconds and fault the

PIR again (the keypad should beep again to confirm). The PIR should

now be learned. A "1" should appear under the "L" on the zone sum-

mary screen. (If an "N" is displayed, the PIR has not been learned.)

6. Press [*] to continue programming zones.

For more information, see the Zone Programming section of the control

panel installation instructions.

Setup and Walk Testing

•

Attach test leads to the Noise Voltage terminals. The outside terminals

are common, and the center terminal is positive.

•

Place the cover on the unit, and twist-lock it clockwise into place.

NOTE:

Be sure the test leads are dressed

through the cutout.

•

Apply power to the unit.

•

Wait at least two minutes, after applying power,

to start walk tests.

NOTE:

Walk testing should be done across the

coverage pattern as shown.

•

The edge of the coverage pattern is determined

when the Alarm/Test LED indicator first turns on.

•

Walk test the unit from all directions to deter-

mine the boundaries.

Wiring

ONLY APPLY POWER AFTER ALL CONNECTIONS

HAVE BEEN MADE AND INSPECTED.

NOTE:

Do not coil excess wiring inside unit.

•

Terminals 1 (-) & 2 (+):

Connect the detector to

the multiplex bus (wire the

detector's T-strip as

shown above.

NOTE:

Polarity must be observed. Improper connection may cause the

multiplex bus to malfunction.

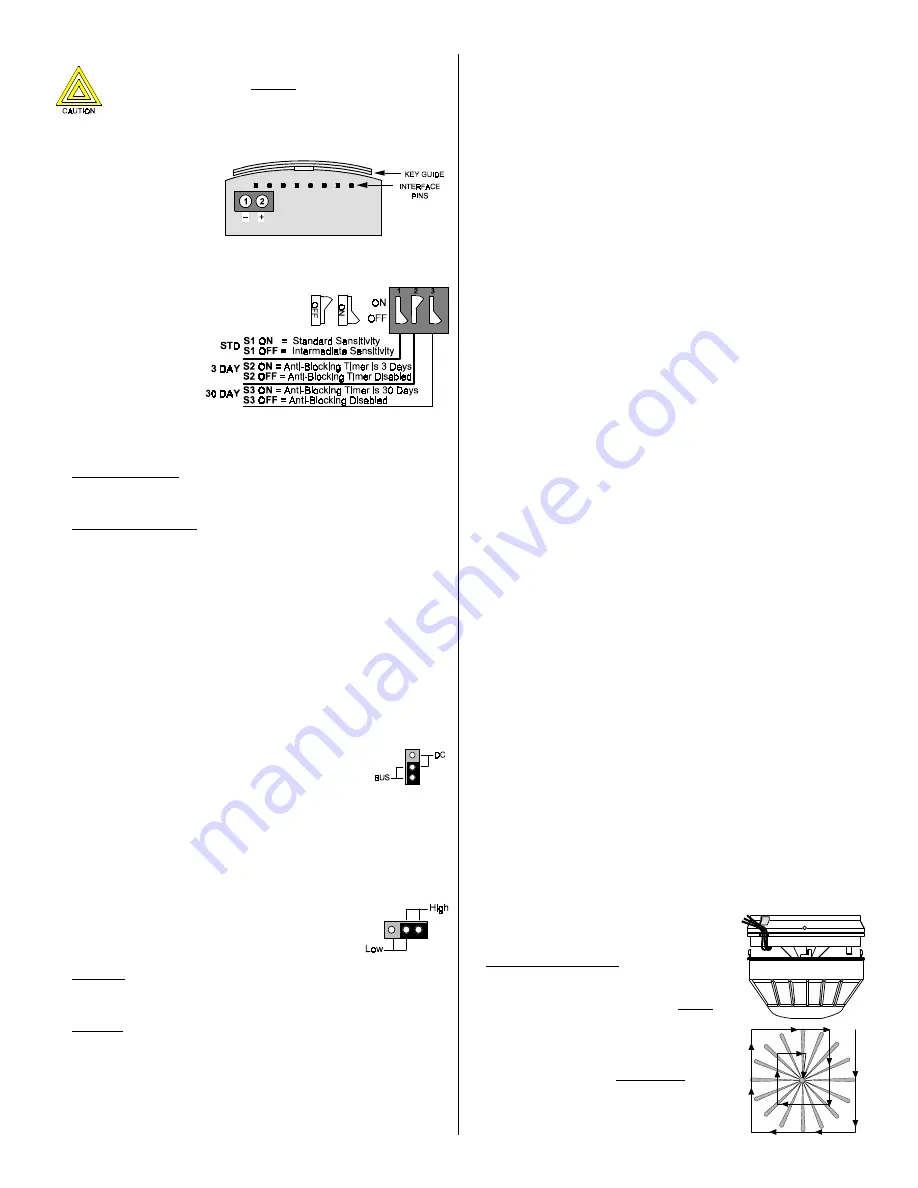

Configuration Switch Settings

The R

X

360SN has several

features that are controlled

using the configuration

switches.

Sensitivity Mode (S1)

Sensitivity modes depend on the type of coverage desired and the

installation environment.

•

Standard Sensitivity: Tolerates environment extremes on this setting,

but requires the largest amount of intruder motion to achieve an alarm.

The detector is shipped in Standard Sensitivity mode.

•

Intermediate Sensitivity: The recommended setting for most installa-

tions. Use in locations where an intruder is expected to cover only a

small portion of the protected area. Tolerates normal environments on

this setting

NOTE:

Although the sensitivity modes provide different degrees of

tolerance to environmentally caused alarms, the installer should

assure peak background noise voltage readings do not exceed

±0.15 VDC.

Anti-Blocking Timer (S2 and S3)

Set switches S2 and S3 for the desired anti-blocking timer time. To

select 3 or 30 days, put its switch in the ON position. If both switches are

OFF, the anti-blocking timer defaults to 30 days. The detector is

shipped with the anti-blocking timer disabled.

Bus/DC Jumper

The detector is shipped with this jumper in the "BUS"

position.

•

During normal operation, this jumper should be in the "BUS" operation.

•

For walk testing or location testing, the detector can be temporarily

operated on 6 to 15VDC source. When operating from a DC source,

the jumper should be in the "DC" position. This will cause the LED to

follow the detector alarm state.

Signal Gain

The R

X

360SN permits selection of the signal gain

depending upon the environment to be protected. The

gain select jumper is located under the optical module.

•

High Gain: Recommended for large coverage applications up to 60 ft.

(18.3 m) in diameter. The R

X

360SN is shipped in this setting. If the gain

select jumper is missing, the unit will default to High Gain.

•

Low Gain: Recommended for applications where the area to be cov-

ered is 40 ft. (12.2 m) or less in diameter and for applications where

High Gain may be too sensitive for environmental extremes.

NOTE:

Setting the R

X

360SN for Low Gain reduces the coverage area

to 40 ft. (12.2 m) in diameter.

www.PDF-Zoo.com