Page 3

Final Tests

Noise Measurement

NOTE:

Meter readings are very important in determining background

disturbance levels and catch margin sensitivity.

•

Connect a 20,000 ohm/volt (or greater) DC VOM to the Noise Voltage

connector using the test leads as shown. Set meter scale for about

3.0 VDC.

•

The base reference level for reading background

noise or target voltages is approximately 2.0 VDC.

Installations in quiet environments, therefore, will

result in a steady meter reading between 1.9 and

2.1 VDC. Look for areas and sources of thermal dis-

turbances if the meter fluctuates greatly.

False Alarm Prevention

•

Turn on all heating and cooling sources that would normally be in op-

eration during times of protection. Stand away from the unit and out-

side the coverage pattern, then monitor the background noise for at

least three minutes.

Readings should not deviate from the reference level more than ±0.15

VDC. For readings outside these limits; eliminate the cause, rotate the

unit slightly, or mask out the mirror segment(s) looking down at the

thermal disturbance.

Coverage Margin

•

Again walk across the farthest edge of required coverage.

A minimum voltage change of 1.0 VDC from the reference level is

required in the wintertime when the background temperature is cool.

This will make up for summertime, when the background is warmer. If

testing the unit in the summertime, the minimum recommended volt-

age change is 0.75 VDC.

•

When testing is completed, remove the test leads, and twist-lock the

cover into place.

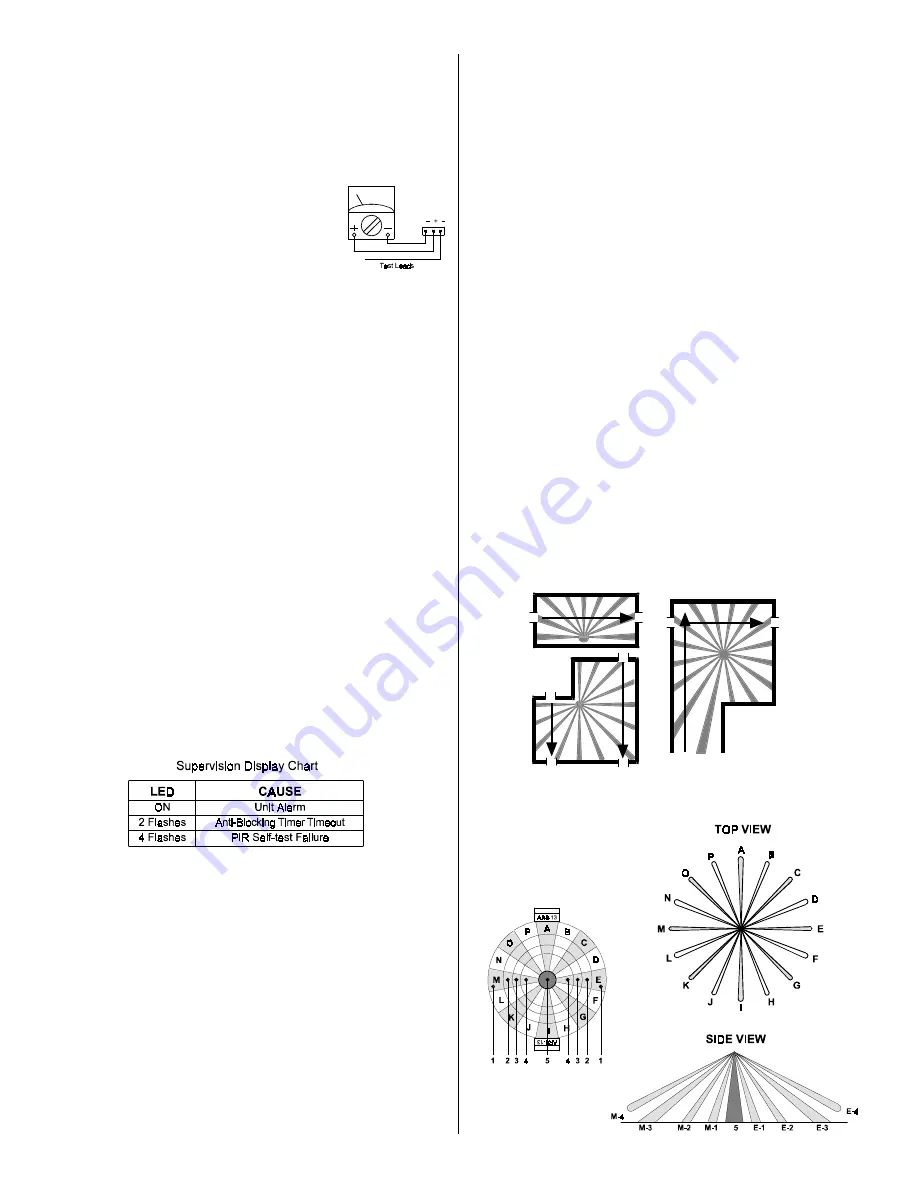

Supervision Features

The R

X

360SN performs several supervision features that, combined with

the advanced motion detection capabilities of the detector, provide an

extremely high level of security. A supervision trouble condition is

indicated at the detector by the Alarm/Test LED (see the Supervision

Display Chart).

•

The LED indicates the cause of the supervision trouble using coded

pulses.

The supervision features function as follows:

•

PIR: The operation of the PIR is electronically checked approximately

every 12 hours, even without motion. The test may also be initiated by

the multiplex control. If the PIR fails, the Alarm/Test LED will flash four

times per second and a trouble signal will be sent to the multiplex

control.

•

Anti-Blocking Timer Supervision: This feature verifies that the de-

tector has a clear view of the detection area and has not been blocked.

A trouble condition will be indicated if the detector has not alarmed at

least once during the selected time period.

Refer to

Configuration Switch Settings for proper switch settings.

If the time period selected has elapsed from the last alarm and no

motion has been sensed by the detector, the LED will flash two times

per second and a trouble signal will be sent to the multiplex control.

The anti-blocking timer time period may be set for 3 to 30 days. This

feature may also be disabled by setting the anti-blocking timer configu-

ration switches S2 and S3 in the OFF position.

Other Information

Anti-vandal Tie-down

•

After the cover has been installed and twisted into place, the entire

assembly can be secured together using the supplied anti-vandal

screws. There are two of them; one for each side.

Optical Module Masking

•

Peel-off masks are provided with the unit for each segment of the opti-

cal module to allow for customized coverage, or to block out areas of

objects that may cause thermal disturbances. The mask is self-adhe-

sive and pre-cut in the shape of the optical module.

•

To block out a particular zone or group of zones, peel off a section of

the mask that corresponds to the appropriate zone, and stick it on the

mirror segment. See

Mirror Module to Pattern Reference to identify

mirror segments and zones.

Maintenance

•

At least once a year, the range and coverage should be checked ac-

cording to

Setup and Walk Testing and Final Tests above.

•

To ensure continued daily operation, the end user should be instructed

to daily walk through the far end of the coverage pattern. This assures

an alarm output prior to arming the system.

U. S. Patent Numbers

•

The R

X

360SN is protected by the following U. S. patents: #4,764,755,

#5,083,106, and #5,670,943.

Typical Placements to Achieve Coverage

Mirror Module to Pattern Reference

www.PDF-Zoo.com