Tightening Bolt

CAUTION:

1. Set the tap position at the low speed.

2. Make sure that the driver bit is inserted

vertically in the bolt head, or the bolt or the

bit may be damaged.

3. Please choose suitable torque according to your operational need.

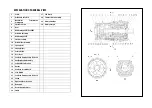

To tighten bolt, hammer the point of the driver bit at the bolt head and force the tool properly.

Switch on the tool slowly and then speed it

up gradually. Once the clutch is closed,

release the switch trigger. (Fig 14)

When tightening wood screws, drill a center

hole first to make tightening action much

easier and to prevent workpiece from

sliding. Please refer to the following sheet:

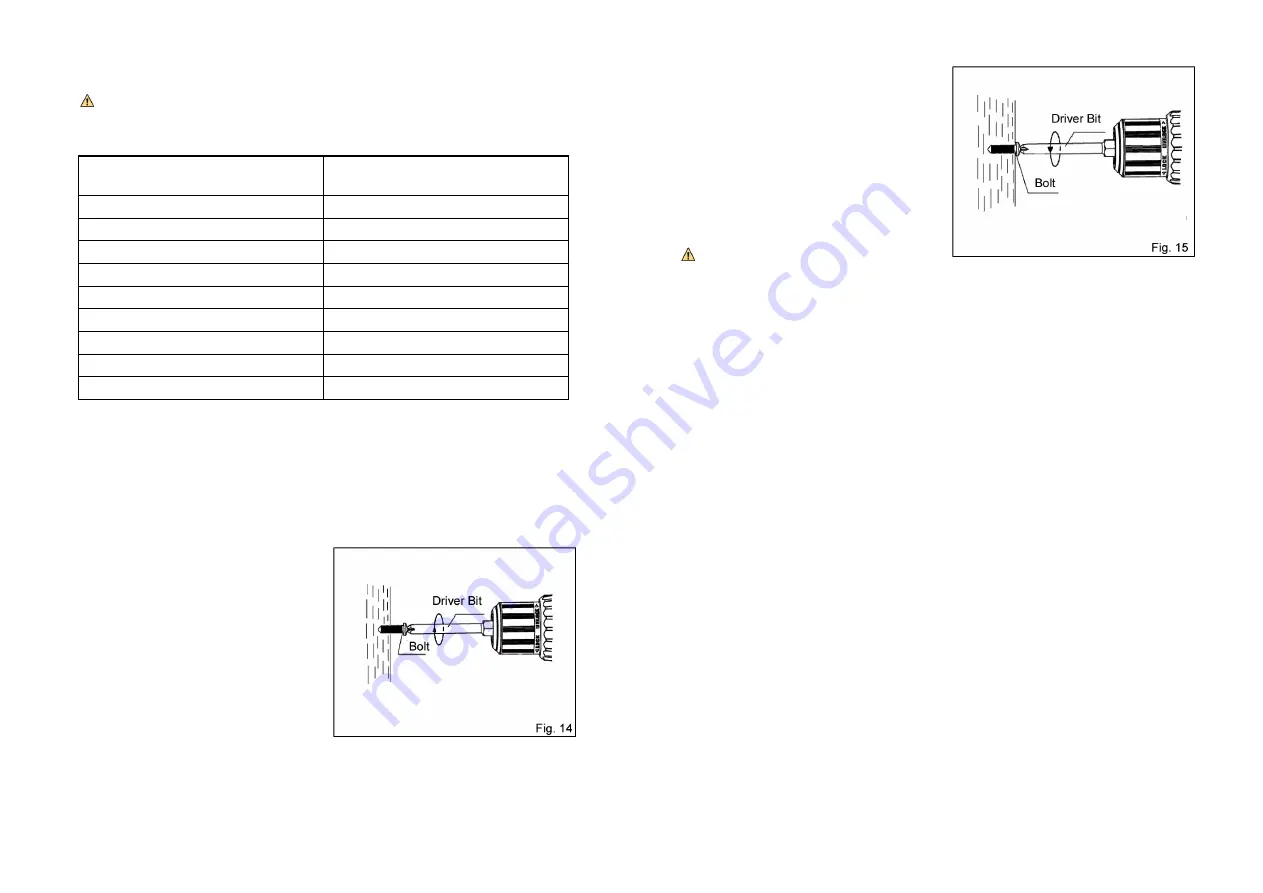

Removing Bolt

To remove the bolt, hammer the point of the

driver bit at the bolt head and force the tool

properly. Switch on the tool slowly and then

speed it up gradually. Once the bolt is taken out,

release the switch trigger. (Fig 15)

Spindle Locking

CAUTION:

Do not press the switch trigger forcibly when the tool is used as hand tool, or the tool will be

damaged.

When the switch trigger is not pressed, the drill spindle is locked. This enables screws to be

screwed in even when the battery runs out and allows the tool to be used as hand tool.

Over-load Protection

The motor will stop running when it is overloaded. To restart the tool, release the switch

trigger first to reset the switch and then switch on the machine

Overheated Protection

When using as intended for, the tool cannot be subject to overload. When the load is too high

or the allowable battery temperature of 75

℃

is exceeded, the electronic control will shut off

the tool until the temperature is in the optimum temperature range again.

Deep Discharging Protection

The tool is equipped with a protective circuit to protect the battery against deep discharging.

When the battery is near to be empty, the protective circuit actuates to switch off the tool.

Disposing of Battery Cartridge

Lithium ion battery is contained in the battery cartridge. For environmental protection,

recycle or dispose of the worn out battery properly. Please consult with your local relevant

departments about how to recycle and/or dispose of the worn out battery.

To recycle or dispose of the worn out battery:

Nominal Diameter

of Wood Screw

(

mm

)

Recommended Size

of Center Hole

(

mm

)

3.1

2.0-2.2

3.5

2.2-2.5

3.8

2.5-2.8

4.5

2.9-3.2

4.8

3.1-3.4

5.1

3.3-3.6

5.5

3.7-3.9

5.8

4.0-4.2

6.1

4.2-4.4

Summary of Contents for MAC AFRIC SDRILC-005

Page 1: ......