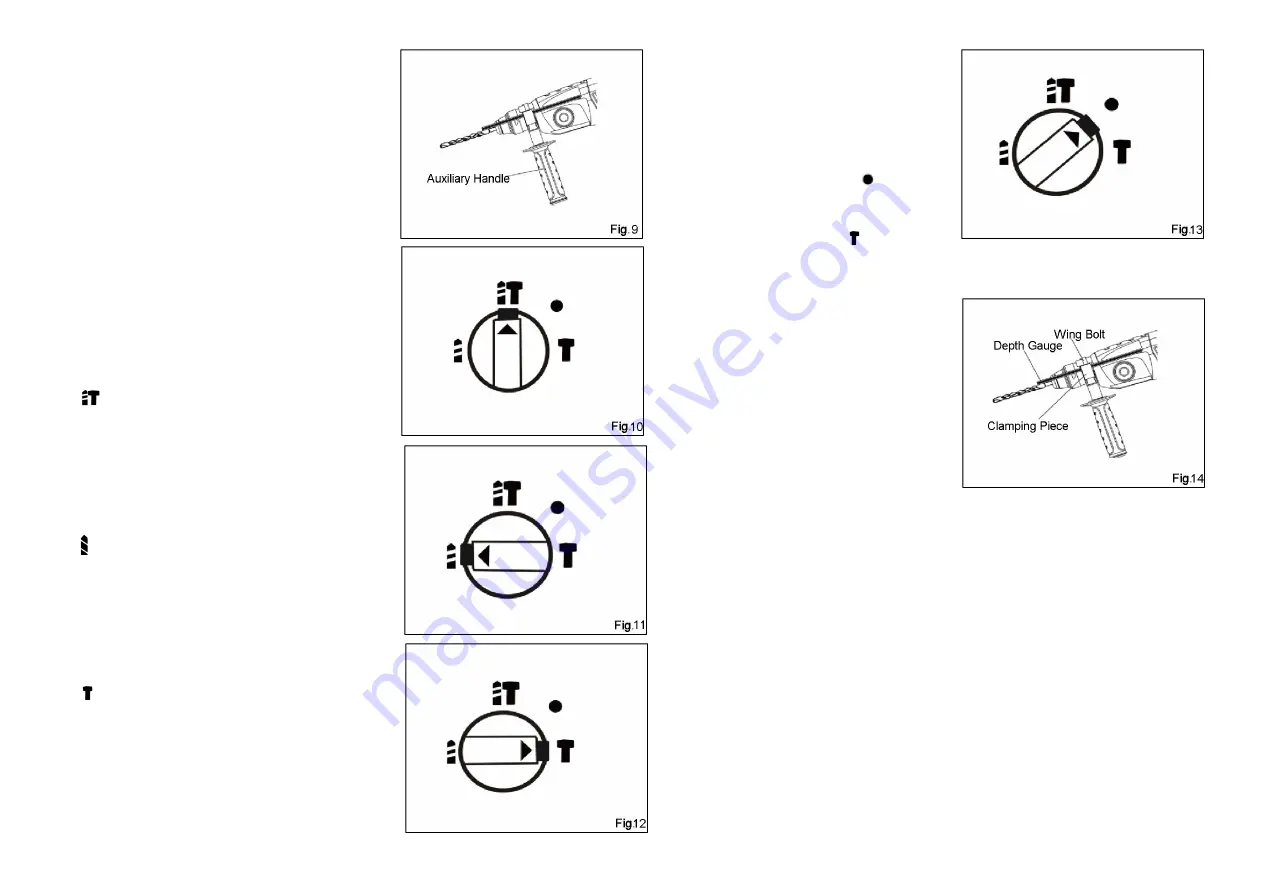

Auxiliary Handle

Always use the auxiliary handle to ensure operating

safety. Make sure that the auxiliary handle is on the

appointed place of the tool, and is tightened securely.

The auxiliary handle can be adjusted to any angle by

loosening it counterclockwise. (Fig. 9)

Setting Operating Mode

The Operating mode can be changed by turning the

operating mode selector.

1.

Hammer Operation

Turn the operating mode selector (without pressing the

lock button), and align the triangle symbol

△

with the

as shown in the figure, then the tool is set in

hammer operation. Set like this when drilling on the

concrete or stone, and use carbide bits. (Fig. 10)

2.

Drill Operation

Turn the operating mode selector (without pressing the

lock button), and align the triangle symbol

△

with the

as shown in the figure, then the tool is set in drill

operation. Set like this when drilling on the wood, metal,

or plastic, and use twist bits or solid center bits. (Fig. 11)

3.

Demolition Operation

Turn the operating mode selector (without pressing the

lock button), and align the triangle symbol

△

with the

as shown in the figure, then the tool is set in

demolition operation. Set like this when chiseling,

scaling or demolishing, and use chisel, scaling chisel and

so on. (Fig. 12)

Bit Angle

When using the tool for demolition operation, to

change the drill angle, turn the operating mode

selector (without pressing the lock button), and

align the triangle symbol

△

with

. Adjust the

bit to the desired angle, and then return the

operating mode selector to the

symbol. (Fig.

13)

Depth Gauge

The depth gauge enables the drilling depth to be

set for convenient drilling holes of uniform depth.

Loosen the auxiliary handle, and insert the linear

part of the depth gauge into the fitting hole of the

clip board. (Fig. 14)

Move the depth gauge to the desired depth and

secure it by rotating the auxiliary handle

clockwise

.

Drilling Action

1.

Hammer Drill Operation

CAUTION:

Applying more pressure will not speed up the drilling. In fact, this excessive pressure will

damage the drill bit, decrease the tool performance, and shorten the service life of the tool.

There is a tremendous force exerted on the bit at the time of hole breakthrough. Be careful

and hold the tool firmly when the bit begins to break through the workpiece.

A stuck bit can be removed simply by setting the reversing switch to reverse rotation in

order to back out. Hold the tool firmly before starting the tool to remove the bit easily.

Do not drill in the material that may contain nails or something that may hamper or destroy

the drill bit.

-14-

Summary of Contents for MAC AFRIC SDRILC-024

Page 1: ......