Chapter 8 - Maintenance

78

Adept Cobra s350 User’s Guide, Rev. A

8.2

Checking of Safety Systems

These tests should be done every six months.

1. Test operation of:

• E-Stop button on Front Panel

• E-Stop button on pendant

• Enabling switch on pendant

• Auto/Manual switch on Front Panel

NOTE:

Operating

any

of the above switches should disable High Power.

2. Test operation of any external (user supplied) E-Stop buttons.

3. Test operation of barrier interlocks, etc.

8.3

Checking Robot Mounting Bolts

Check the tightness of the base mounting bolts every 6 months. Tighten to 70 N•m

(63 ft-lb). Also check the tightness of all cover plate screws.

8.4

Lubricate Joint 3 Ball Screw

Required Grease for the Robot

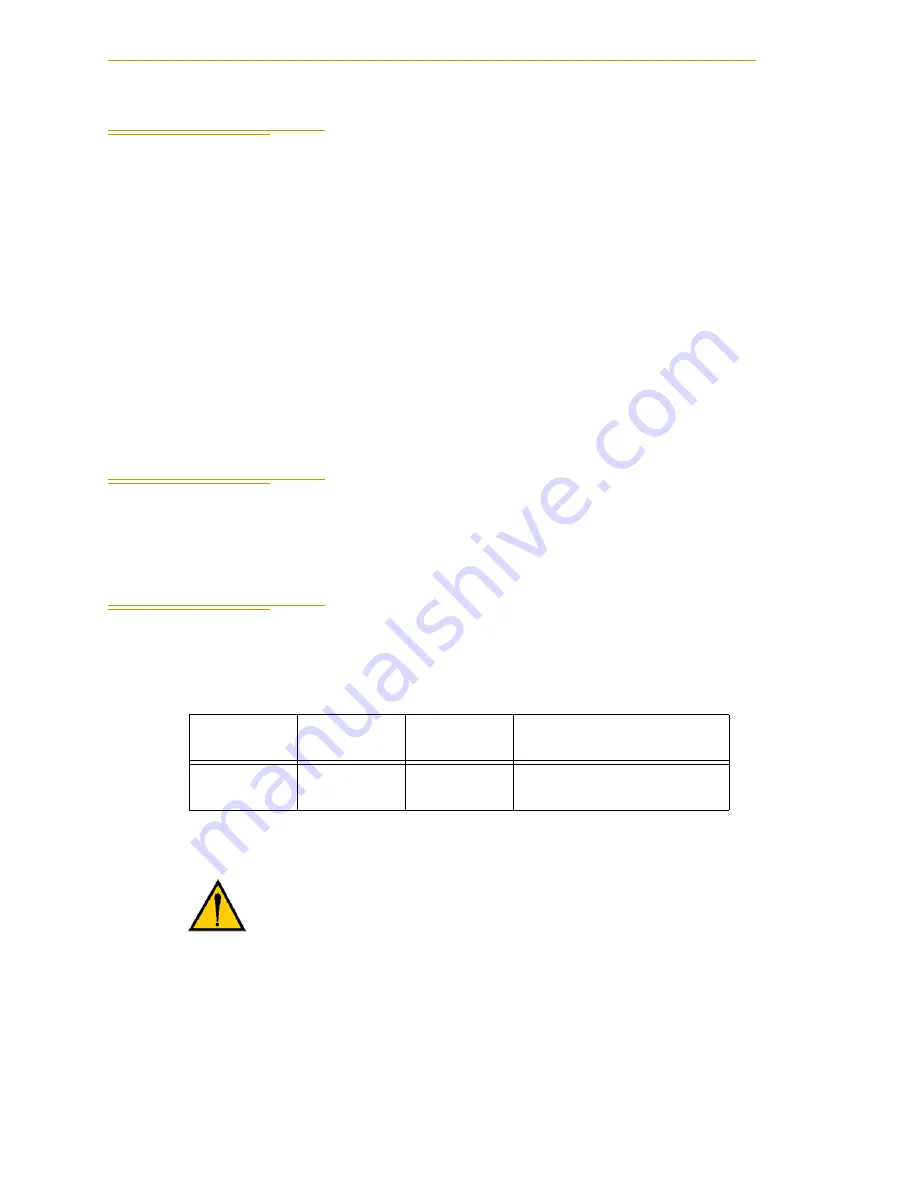

Table 8-2.

Lubrication

Point

Lubrication

Type

Lubrication

Amount

Remarks

Joint 3 quill

shaft

Epinoc AP1

2 to 3 cc

Apply grease to entire shaft.

CAUTION:

Using improper lubrication products on the

Adept Cobra s350 robot may cause damage to the robot.

Summary of Contents for Cobra s350

Page 1: ...Adept Cobra s350 Robot User s Guide...

Page 2: ......

Page 16: ...Chapter 1 Introduction 16 Adept Cobra s350 User s Guide Rev A...

Page 34: ...Chapter 3 Robot Installation 34 Adept Cobra s350 User s Guide Rev A...

Page 50: ...Chapter 4 MotionBlox 40R 50 Adept Cobra s350 User s Guide Rev A...

Page 62: ...Chapter 5 System Installation 62 Adept Cobra s350 User s Guide Rev A...

Page 66: ...Chapter 6 System Operation 66 Adept Cobra s350 User s Guide Rev A...

Page 84: ...Chapter 8 Maintenance 84 Adept Cobra s350 User s Guide Rev A...

Page 90: ...Chapter 9 Technical Specifications 90 Adept Cobra s350 User s Guide Rev A...

Page 98: ...Chapter 10 Cleanroom Robots 98 Adept Cobra s350 Robot User s Guide Rev A...

Page 102: ...Index 102 Adept Cobra s350 User s Guide Rev A...

Page 103: ......

Page 104: ...3011 Triad Drive Livermore CA 94551 925 245 3400 P N 05624 000 Rev A...