Chapter 8 - Technical Specifications

108

Adept Cobra s600/s800 Robot User’s Guide, Rev H

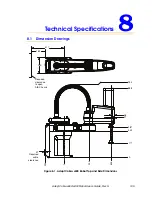

Figure 8-4. Tool Flange Dimensions for Adept Cobra Robots

4X M6 x 1- 6H Thr

u

User Gro

u

nd

See Detail A

Detail A

6.

8

0 mm

(0.26

8

in.)

1.5 mm

(0.059 in.)

4.14 mm

(0.163 in.)

12.0 mm

(0.47 in.)

20.0 mm

(0.79 in.)

3.0 mm

(0.12 in.)

43 mm

(1.69 in.)

30

˚

25

˚

45˚

∅

41.15 mm

∅

63.0 mm (2.4

8

in.)

Dowel Pin Hole

C

B

A

∅

.10 mm (.004 in.)

∅

50.0 mm (1.96

8

5 in.)

BC

∅

6.0 mm

-C-

-A-

-B-

+.03 mm

–.00 mm

(

∅

1.620 in.) (+.001 in.)

(–.000 in.)

M

M

M

R 3.56mm (R 0.140in)

5.0

8

mm (0.20in)

M3 X 0.5-6H Thr

u

(0.2362 in.)

+.01 mm

– 0 mm

(+.0005 in.)

(– 0 in.)

Summary of Contents for Cobra s600

Page 1: ...Adept Cobra s600 s800 Robot User s Guide...

Page 2: ......

Page 14: ......

Page 20: ......

Page 52: ......

Page 68: ......

Page 80: ......

Page 116: ......

Page 132: ......

Page 146: ......

Page 151: ......

Page 152: ...5960 Inglewood Drive Pleasanton CA 94588 925 245 3400 P N 03017 000 Rev H...