Chapter 7 - Optional Equipment Installation

82

Adept Cobra s600/s800 Robot User’s Guide, Rev H

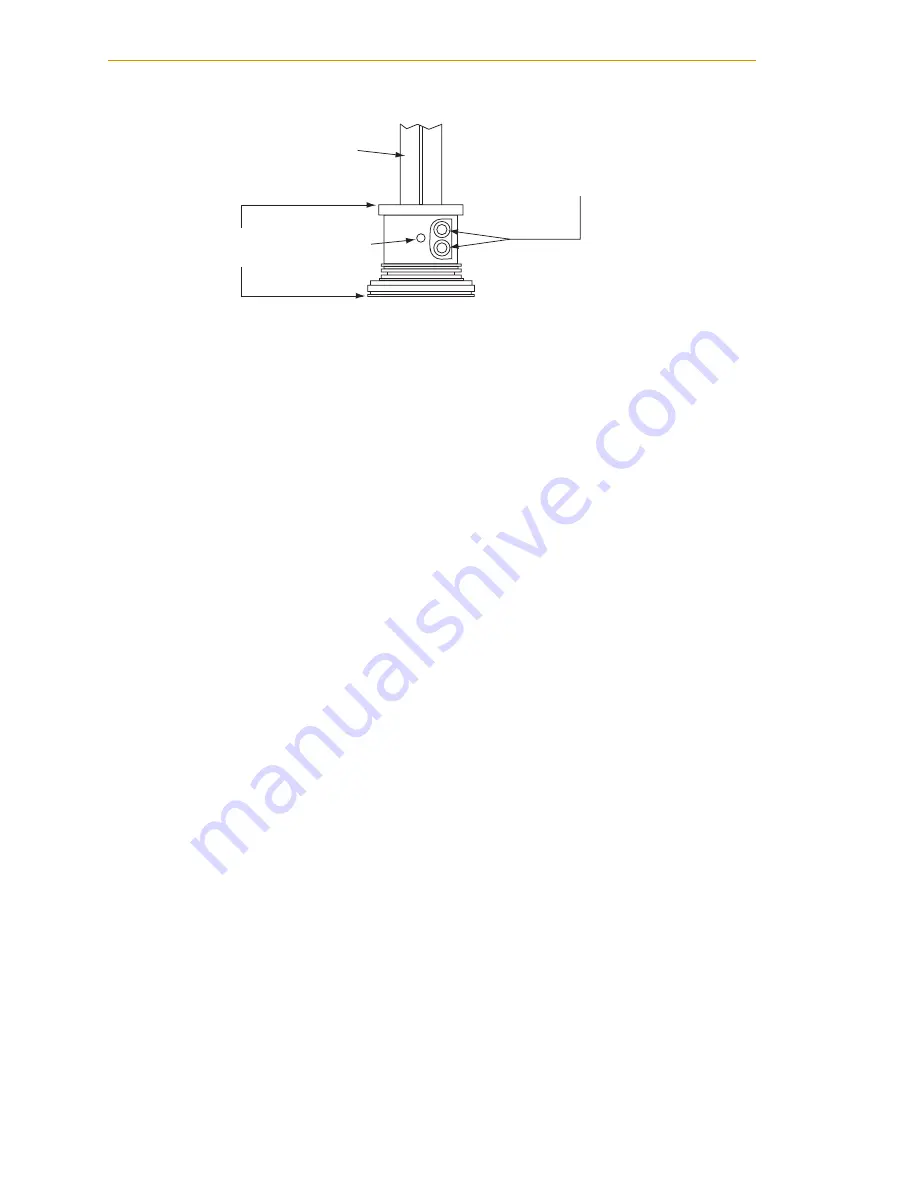

Figure 7-1. Tool Flange Removal Details

Installing the Flange

1. Make sure the steel ball is in the setscrew hole inside the flange. Hold it in place

with your finger as you get ready to install the flange.

2. Slide the flange up on the quill shaft as far as it will go, and rotate until the

setscrew is lined up with the original vertical groove.

3. Support the flange while using a 2.5 mm Allen wrench to tighten the setscrew to

finger tight. Do not over-tighten the setscrew because this will cause the flange to

be off-center from the quill shaft.

4. Use a socket driver to tighten one of the socket-head screws part of the way, then

tighten the other one the same amount. Alternate between the two screws so there

is even pressure on both once they are tight. The torque specification for each

screw is 8 N•m (70 in-lb).

User flan

g

e

assem

b

ly

Setscrew

M4 Socket-head

cap screws

Q

u

ill shaft

Summary of Contents for Cobra s600

Page 1: ...Adept Cobra s600 s800 Robot User s Guide...

Page 2: ......

Page 14: ......

Page 20: ......

Page 52: ......

Page 68: ......

Page 80: ......

Page 116: ......

Page 132: ......

Page 146: ......

Page 151: ......

Page 152: ...5960 Inglewood Drive Pleasanton CA 94588 925 245 3400 P N 03017 000 Rev H...