Chapter 6 - Optional Equipment Installation

70

Adept Cobra s800 Inverted Robot User’s Guide, Rev C

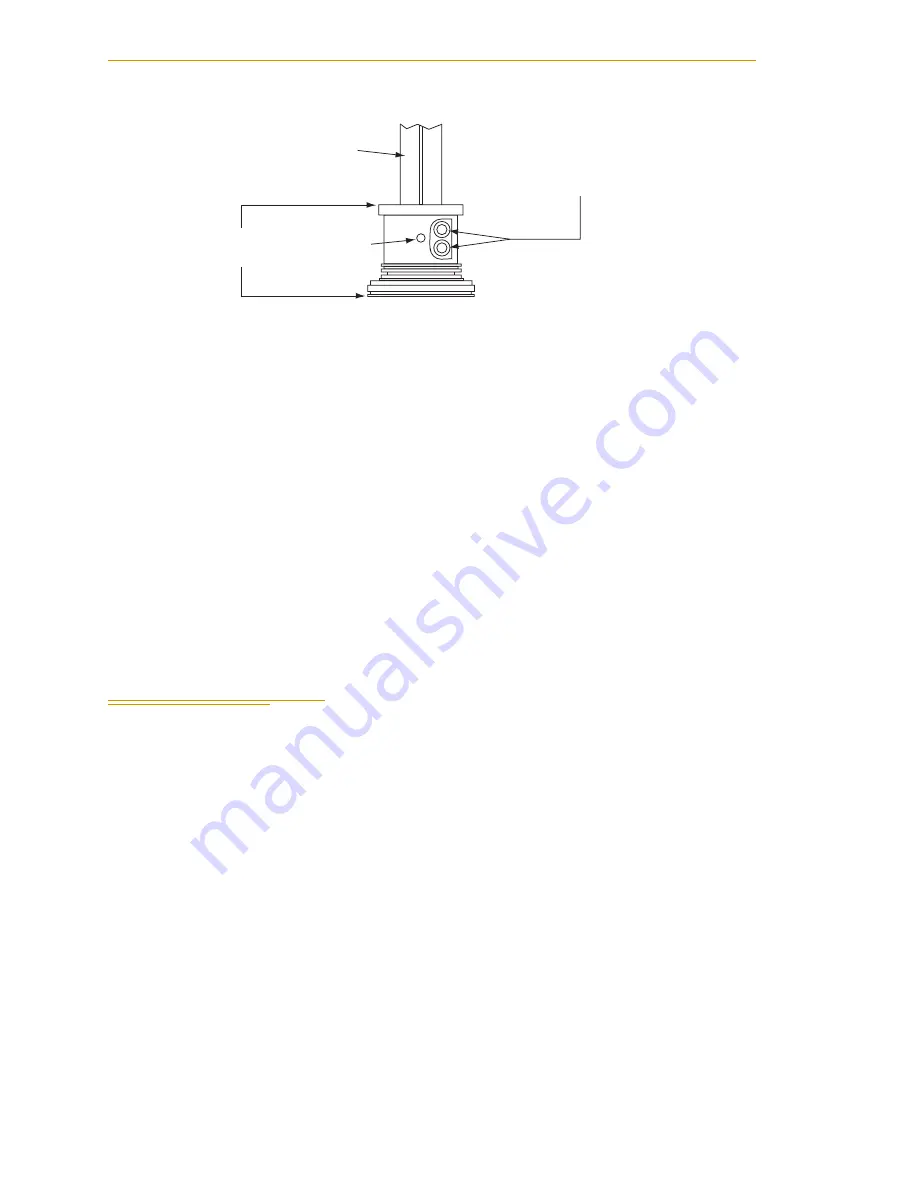

Figure 6-1. User Flange Removal Details

Installing the Flange

1. Make sure the ball bearing is in the setscrew hole inside the flange. Hold it in

place with your finger as you get ready to install the flange.

2. Slide the flange up on the quill shaft as far as it will go, and rotate until the

setscrew is lined up with the original vertical groove.

3. Support the flange while using a 2.5 mm Allen driver to tighten the setscrew to

finger tight. Do not over-tighten the setscrew because this will cause the flange to

be off-center from the quill shaft.

4. Use a socket driver to tighten one of the socket-head screws part of the way, then

tighten the other one the same amount. Alternate between the two screws so there

is even pressure on both once they are tight. The torque specification for each

screw is 8 N

·

m (70 in-lb).

6.3

User Connections on Robot

User Air Lines

There are five user air line connectors on the robot user panel on the back of Joint 1 (see

). The five air lines run through the robot up to another set of five matching

connectors on the top of the outer link. See

NOTE:

On the IP-65 version robot, the connectors are under the outer link

cover. See

.

• The two larger connectors are 6 mm diameter.

• The three smaller connectors are 4 mm diameter.

User flange

assembly

Setscrew

M4 Socket-head

cap screws

Quill shaft