- 16 -

Trouble Shooting

This section provides an easy reference guide to the more common problems that may occur during the

operation of your equipment. The fault finding guide in this section is intended to help you correct, or at

least accurately diagnose problems with your equipment.

Although this section covers the most common problems reported, you may encounter a problem not

covered in this section. In such instances, please contact your local authorized service agent who will

make every effort to help you identify and resolve the problem. Please note that the service agent will

require the following information:

•

Model Code and the Serial Number of the appliance. (Both of them can be found on the Rating

Plate located on the appliance).

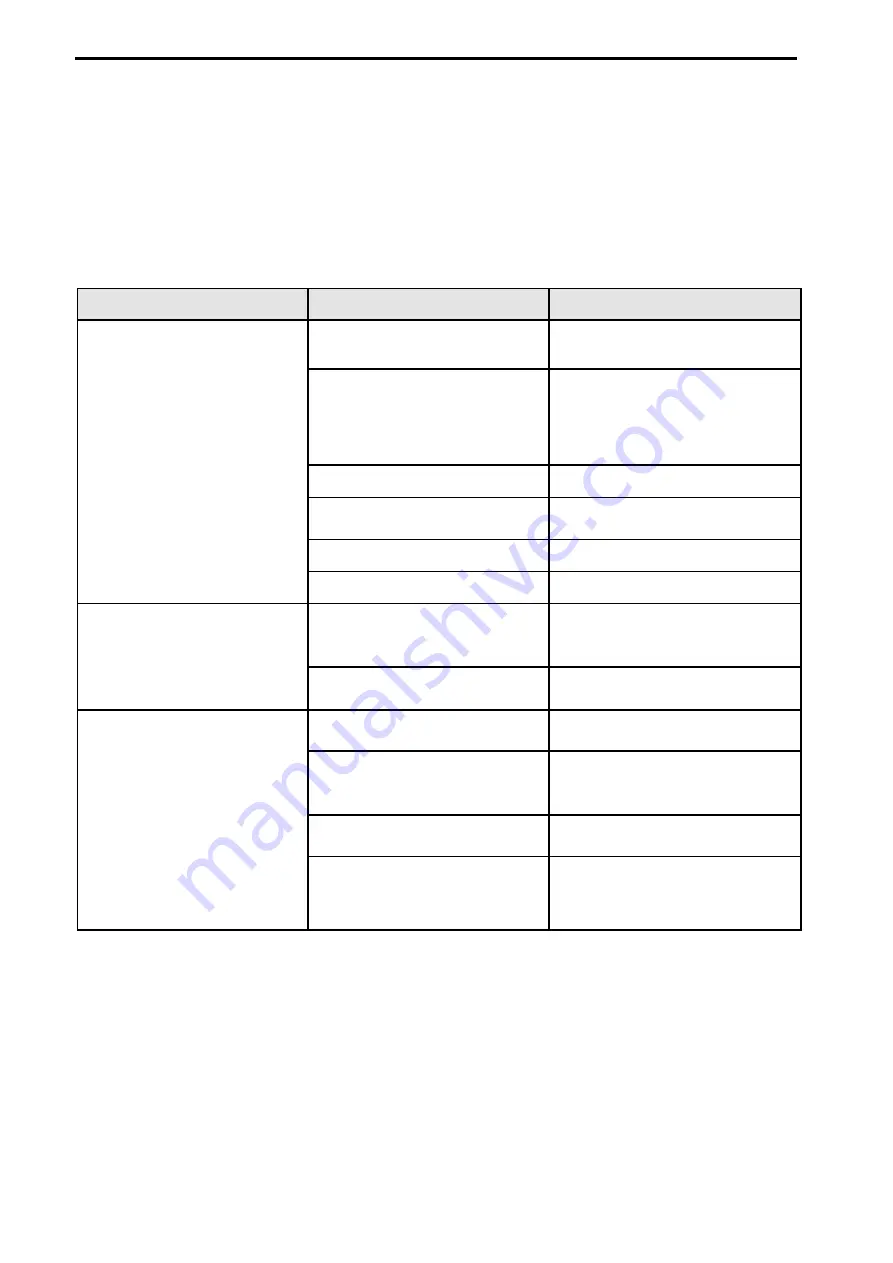

Fault

Possible Cause

Remedy

Main burner will not light.

Insufficient gas pressure

in pipe

Contact the local gas supply dept.

No gas supply.

Ensure gas isolation valve

is turned on, and that

bottles are not empty.

Call the service provider. .

Nozzle occlusion

Dredge nozzle

Thermocouple connection

loose

Tighten thermocouple

Thermocouple damage

Replace thermocouple

Gas control valve failure

Replace control valve

No spark flame on main burner

Faulty battery for

electronic pulse ignition

device

Put No 7 battery into

ignition device

Faulty electronic pulse

ignition device

Replace electronic pulse

ignition device

Yellow flame and black smoke

Use the gas of bottom

Replace gas

Not match nozzle

diameter with gas

resources

Adjust nozzle diameter

Not enough air to ignite

Increase damper opening

degree

In the peak of using

gas, sources of gas float

heavy

Turn down valves flow.

Turn it up after

the peak

The problems mentioned above are only for reference. If any fault occurs, please stop using, and contact

technicians to check and repair. Safety first, turns off the power and gas supply before maintenance.

NOTE:

Components having adjustments protected by the manufacturer are only to be adjusted by an

authorized service agent. They are not to be adjusted by an unauthorized service person.

Summary of Contents for EGG-16S

Page 2: ......

Page 8: ...5 Dimensions EGG 48S EGG 36S EGG 24S EGG 16S...

Page 21: ...18 Explosion Drawing EGG 48S...