GB

GB

ATTENTION:

For the daily recharge of the batteries it is necessary

to follow strictly all the indications given by the

manufacturer/distributor. All the installation and

maintenance operations must be carried out by

qualified staff.

Danger of gas exhalations. Fire

danger: do not approach with free flames.

BATTERIES DISPOSAL

It is compulsory to hand over exhaust batteries, clas-

sified as dangerous waste, to an authorized institu-

tion according to the current laws.

BATTERIES CHARGE LEVEL INDICATOR

The charge level of the batteries is visible by switch-

ing on the machine with the general switch (1).

green led on = batteries charged.

green led blinking = batteries almost discharged.

red led on = complete discharge of the batteries

with consequent automatic switching off of all the

functions (immediate recharge necessary).

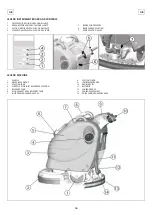

SQUEEGEE ASSEMBLY

With the squeegee support lowered, slide the two

stud bolts (A) placed on the upper part of the squee-

gee, inside the slots on the support. Block the squee-

gee by rotating the lever (B) clockwise.

Insert the squeegee hose (C) into its coupling, re-

specting its position as indicated in the figure.

ADJUSTMENT OF THE SQUEEGEE HEIGHT

The squeegee must be adjusted in height depending

on the rubber wear. In order to guarantee a perfect

drying during the operation, the lower blade of the

rear squeegee rubber (D) must work slightly bent

backwards (operator side) in uniformed way in all its

length.

Acting clockwise upon the two registers (E) it is pos-

sible to increase the bending of the rubber. Acting

counterclockwise it is possible to decrease the rubber

bending.

The label (G) indicates the rotation sense to increase

or reduce the height.

Note: The wheels of the squeegee support must be

adjusted through the registers (E) at the same height

so that the squeegee works parallel to the floor.

ADJUSTMENT OF THE SQUEEGEE INCLINATION

In case of need, to increase the rubber bending in

the central part, it is necessary to tilt the squeegee

body rotating counterclockwise the register (F). To

increase the rubber bending on the squeegee ex-

tremities, rotate the register clockwise.

SPLASH GUARD ASSEMBLY

The two splash guards have to be assembled onto the

brush base group. Insert the metal strips inside the

suitable slots present on the rubber. Place the round

hole at the flat extremity of the strip onto the screw

placed in the front part of the brush base group. Se-

cure the strips through the nut blocking it.

Screw down the knobs in the rear part of the cover

in the free extremity of the metal strips. The opera-

tion has to be carried out for both splash guards.

With the brush assembled, the splash guard must

slightly touch the floor.

BRUSH ASSEMBLY

1. Take off the electric supply to the brush motor

unplugging the connector (1).

2. Take off the squeegee.

3. Lift the support raising the lever.

4. Rotate backwards the machine until it rests on

the support wheels, so to lift the brush base.

5. With the brush base group in lifted position, in-

sert the brush into its plate seat underneath the

brush base turning it until the three metal buttons

are properly seated in their slots; rotate energically

the brush to push the button towards the coupling

spring until it gets blocked.

The figure shows the rotating sense for the brush

coupling.

ATTENTION:

The handling of the brushes operation must be car-

ried out using suitable gloves to protect both me-

chanically from contact with the bristles and the

chemical risk of contact with dangerous solutions.

ATTENTION:

Use only the brush supplied with the machine or the

ones indicated in the paragraph “RECOMMENDED

BRUSHES”. The use of other brushes can compromise

security.

20

Summary of Contents for 48803020

Page 2: ......

Page 14: ...I I 14...

Page 26: ...GB GB 26...

Page 38: ...F F 38...

Page 50: ...D D 50...