GB

GB

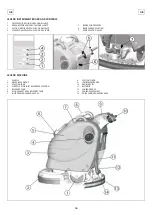

THE BRUSH MOTOR DOES NOT WORK

1. Check the charge level of the batteries that is

visible when switching on the general switch (1) (see

under “BATTERIES CHARGE LEVEL INDICATOR”).

2. Verify that the brush motor switch (2) is activat-

ed checking that its signal lamp is on.

3. Activate the scrub control levers (3).

If the problem persists, please contact the authorized

technical assistance.

INSUFFICIENT WATER ON THE BRUSH

1. Check that the solenoid valve switch (1) is acti-

vated verifying that the signal lamp is on.

2. Check the level of the liquid in the solution tank

(see under “DETERGENT SOLUTION TANK”).

3. Check that the solution flow adjusting knob (2) is

sufficiently open.

4. Press the brush control levers (3).

If the problem persists, please contact the authorized

technical assistance.

THE MACHINE DOES NOT CLEAN PROPERLY

1. The brush does not have the suitable bristle di-

mension: use only original brushes. For advice, con-

tact the authorized technical assistance.

2. The brush has got worn bristles. Check the brush

wear condition and eventually replace it (the brush

has to be replaced when the bristles have reached a

height of about 15mm).

To replace the brush, see instructions at paragraph

“BRUSH DISASSEMBLY” and “BRUSH ASSEMBLY”.

3. The solution detergent is insufficient: open more

the solution valve.

4. Check that the liquid detergent is in the recom-

mended percentage.

Contact the authorized technical assistance for ad-

vice.

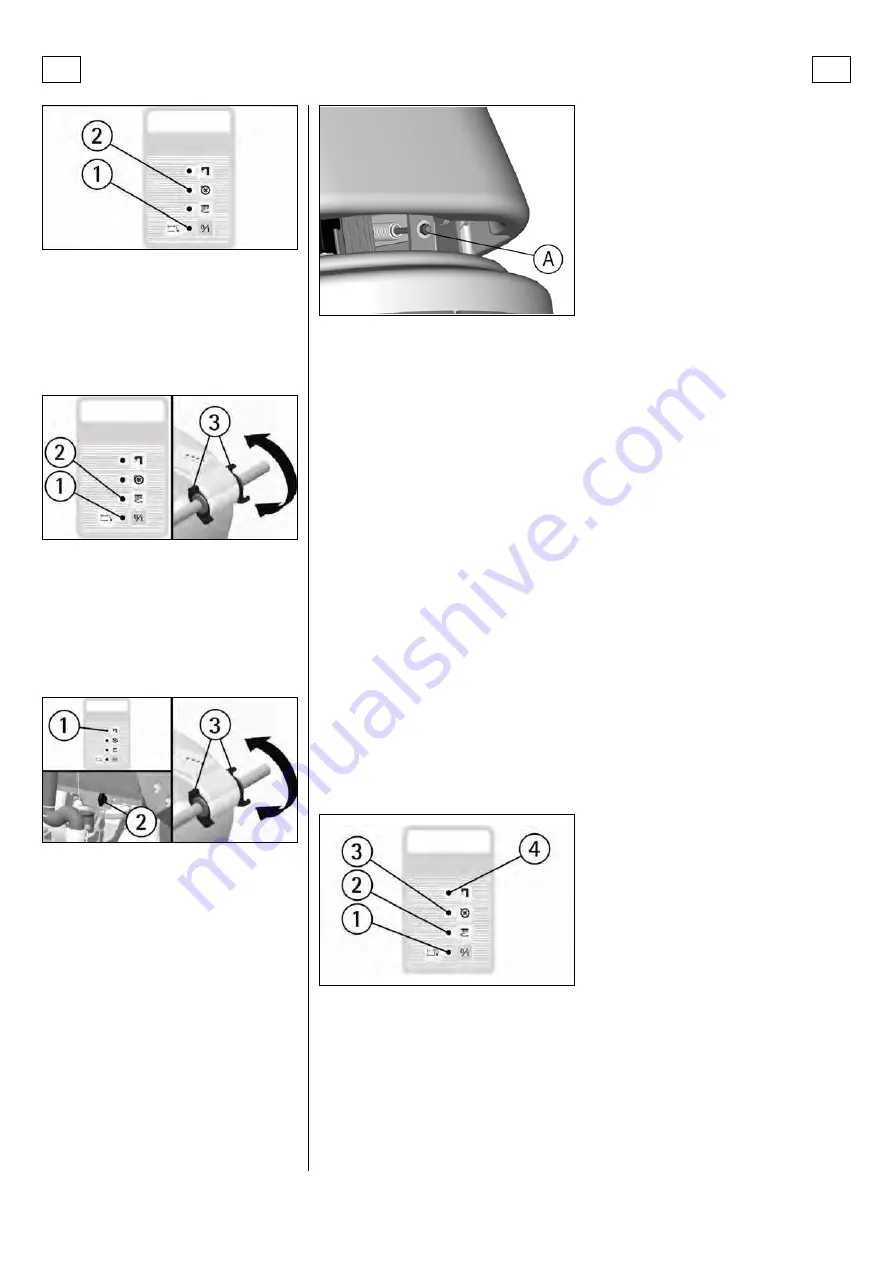

THE MACHINE TENDS TO MOVE SIDEWAYS

Acting upon the adjustment nut (A) placed on the

brush base group, it is possible to correct the direc-

tion of the machine movement. Screw down the nut

to correct the direction to the left, and unscrew it to

increase the direction to the right.

THE SQUEEGEE DOES NOT DRY PERFECTLY

1. Check that the squeegee rubbers are clean.

2. Check the height and inclination of the squeegee

(see section “SQUEEGEE ASSEMBLY” in “BEFORE

USE”).

3. Check that the suction hose is correctly inserted

in the proper seat on the recovery tank.

4. Clean the suction filter.

5. Replace the rubbers if worn out.

6. Check that the suction motor switch is on.

7. Check that the recovery tank is empty.

EXCESSIVE FOAM PRODUCTION

Check that low foam detergent has been used. Even-

tually add small quantities of anti foam liquid into

the recovery tank.

Please be aware that a bigger quantity of foam is

produced when the floor is not very dirty. In this

case please dilute detergent solution.

LED (2), (3) AND (4) BECOME RED

If the machine is in the driving sense, with the gen-

eral switch (1) on and one of the three led (2), (3) or

(4) change colour, from green to red, it means that,

an amperemetric protection is taking place, for ex-

ample:

- LED (2) RED: the brush motor is having too big

stress.

- LED (3) RED: the suction motor is aspirating water

and therefore is forcing too much.

- LED (4) RED: the coil of the solenoid valve may be

short-circuited.

To reset, switch off the general switch (1), wait a few

minutes and then switch on again.

If the problem persists, please contact the authorized

technical assistance.

24

Summary of Contents for 48803020

Page 2: ......

Page 14: ...I I 14...

Page 26: ...GB GB 26...

Page 38: ...F F 38...

Page 50: ...D D 50...