GB

GB

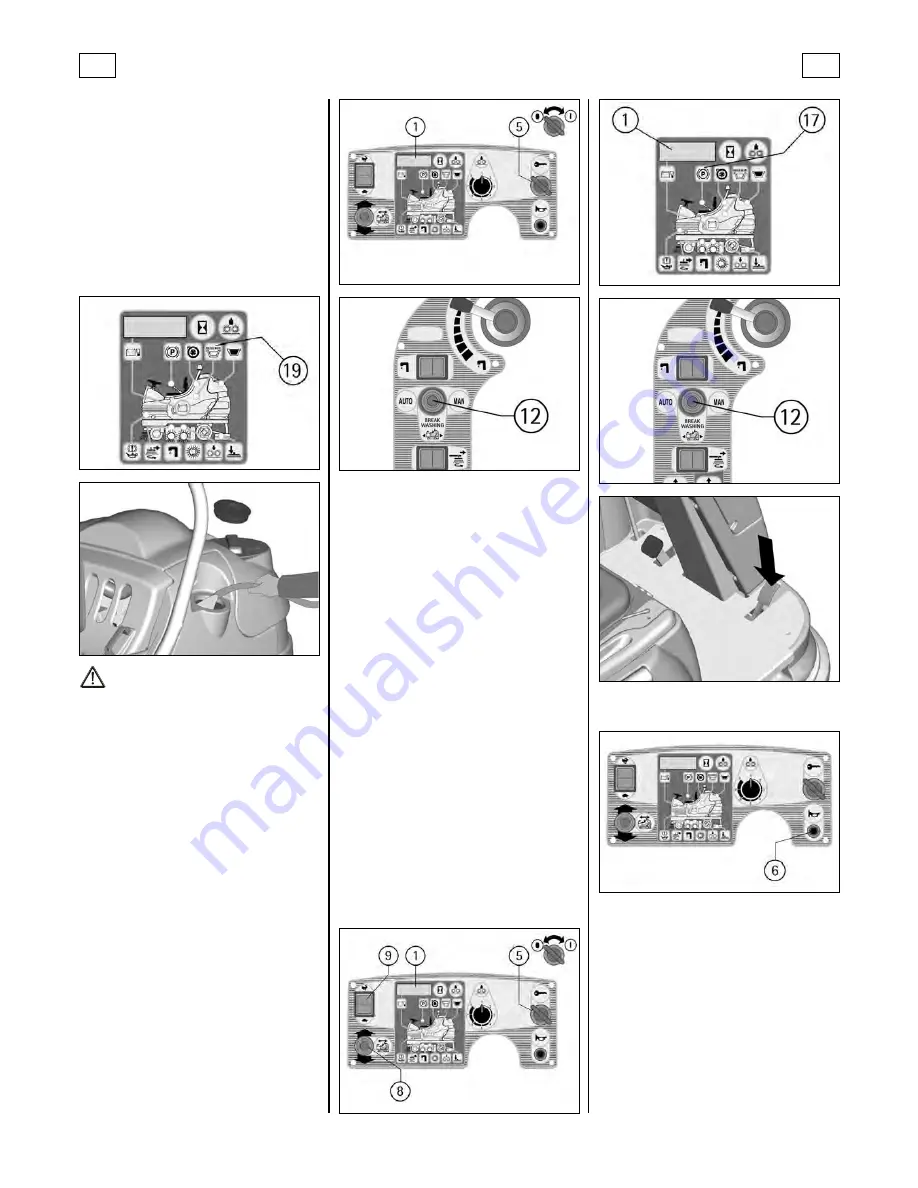

10

DETERGENT SOLUTION TANK

The capacity of the detergent solution tank is indi-

cated in the technical data.

Open the screw plug placed in the left part of the

machine and fill the detergent solution tank with

clean water at a maximum temperature of 50°C. Add

the liquid detergent in the percentage and condi-

tions foreseen by the manufacturer. To avoid exces-

sive foam presence, which could cause problems to

the suction motors, use the minimum percentage of

detergent. Screw down the plug to close the solution

tank.

The switching on of the signal lamp of low detergent

(19) indicates that the detergent solution is nearly

exhausted.

ATTENTION:

Use always low foam detergent. To avoid foam pres-

ence, before starting working operation, introduce

into the recovery tank a minimum quantity of anti-

foam product.

Never use pure acid.

STARTING OF THE MACHINE

A safety device avoids the machine’s movement if

the operator is not seated correctly on the guiding

place.

To switch on the machine:

1. Sit on the guiding place.

2. Turn the key switch (5) clockwise to switch on

the machine.

3. Check the charge level of the batteries on the

display (1).

4. With the selector (12) in central position (BREAK

WASHING) the transfer operations of the machine

are carried out (see under paragraph “FORWARD

AND BACKWARD MOVEMENT").

5. Moving the selector (12) onto the left, the auto-

matic (AUTO) functioning is chosen. Moving it in-

stead onto the right, the functioning of the machine

becomes manual (MAN):

A. If the selector (12) is in position (AUTO) the ma-

chine activates and deactivates all the working func-

tions in an automatic mode (see under paragraph

“WORKING IN AUTOMATIC MODE”).

B. If the selector (12) is in position (MAN) every

function of the machine has to be activated or deac-

tivated manually (see under paragraph “WORKING IN

MANUAL MODE”).

FORWARD AND BACKWARD MOVEMENT

It is recommendable to carry out always the mere

transfer of the machine in mode (BREAK WASHING).

To proceed to activate the movement of the machine:

1. Sit on the guiding place.

2. Turn the key switch (5) clockwise to switch on

the machine.

3. Check the charge level of the batteries on the

display (1).

4. Release the parking brake. If the brake was in-

serted, the signal lamp (17) would be switched on

(see under paragraph "EMERGENCY-PARKING

BRAKE”).

5. Bring the selector (12) in central position (BREAK

WASHING) to carry out the mere transfer of the ma-

chine. In fact, in this mode the washing functions of

the machine are not working and only the traction

system functions.

6. Select the driving sense with the selector (8).

7. Press onto the accelerator pedal placed on the

right side to start the machine.

8. Adjust the driving speed in forward choosing the

slow one (at the maximum you can reach 4,5 km/h)

or, pressing the same selector (9) upwards, the faster

one (at the maximum you can reach 7 km/h) can be

obtained.

In backward movement, when the machine is mov-

ing, an intermittent warning device is activated.

9. The machine is equipped with an automatic sys-

tem that reduces the speed when the drive direction

is changed. The speed reduction is as higher as

sharper is the curve.

The speed returns again normally as soon as the ma-

chine gets out from the curve and it runs along

straight paths.

HORN

The machine is equipped with a horn which is acti-

vated pressing the push button (6).

WORKING BRAKE

The machine is equipped with a hydraulic braking

system that acts on the rear wheels.

To brake it is sufficient to press the pedal placed at

the left side of the steering column releasing instead

the accelerator pedal.