GB

GB

15

5. Rinse with a water jet the solution tank and the

components of the filter.

6. Reassemble all parts.

NOTE: in case of need it is possible to wash only the

components of the outer solution filter as above-

mentioned by closing the solution valve adjustment

(see under paragraph “FLOW ADJUSTMENT OF THE

DETERGENT SOLUTION”), so that the detergent solu-

tion remains in the solution tank.

TWO-MONTHLY MAINTENANCE

FRONT SQUEEGEE RUBBER CHECK

Check the wear of the squeegee rubber and eventu-

ally replace it.

For the replacement it is necessary to:

1. Take off the squeegee (see under paragraph

“SQUEEGEE CLEANING”).

2. Unscrew the wing nuts in the front part of the

squeegee.

3. Take off the rubber holder blade.

4. Replace the front rubber.

5. Reassemble all parts.

SIX-MONTHLY MAINTENANCE

SPLASH GUARD RUBBER CHECK OF THE SIDE

BRUSH

With the brush assembled, the splash guard of the

side brush must slightly touch the floor. If the rubber

is worn, it has to be replaced.

The device has to be in rest position at machine stop.

ATTENTION:

To carry out above operations with the electric sup-

ply on, may cause damages to hands.

To replace the rubber:

1. Take off the side brush (see under paragraph

“SIDE BRUSH ASSEMBLY AND DISASSEMBLY”).

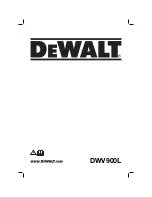

2. Take off the screws (1) that block the rubber

blade and replace the rubber.

3. Reassemble all parts.

CHECK OF THE BRAKES

Check the braking efficacy of both rear wheels.

Should the braking be insufficient, please contact

the authorized technical assistance.

TROUBLESHOOTING GUIDE

NOTE: The machine is equipped with a control sys-

tem of the main functions with indication on the

display of a probable malfunction with codified

alarms: AL 01, AL 02, etc. The alarm 20 is general and

foresees and additional check of the quantity of

blinkings to be read on the led placed on the chop-

per card.

ATTENTION:

If with the key switch positioned clockwise to switch

on the machine the display and other functions are

not activated, it is necessary to check the batteries'

connection to the machine (see under paragraph

“CONNECTION BATTERIES' CONNECTION AND

SWITCHING ON OF THE MACHINE”). If the problem

persists, please contact the authorized technical as-

sistance.

THE SUCTION MOTOR DOES NOT WORK

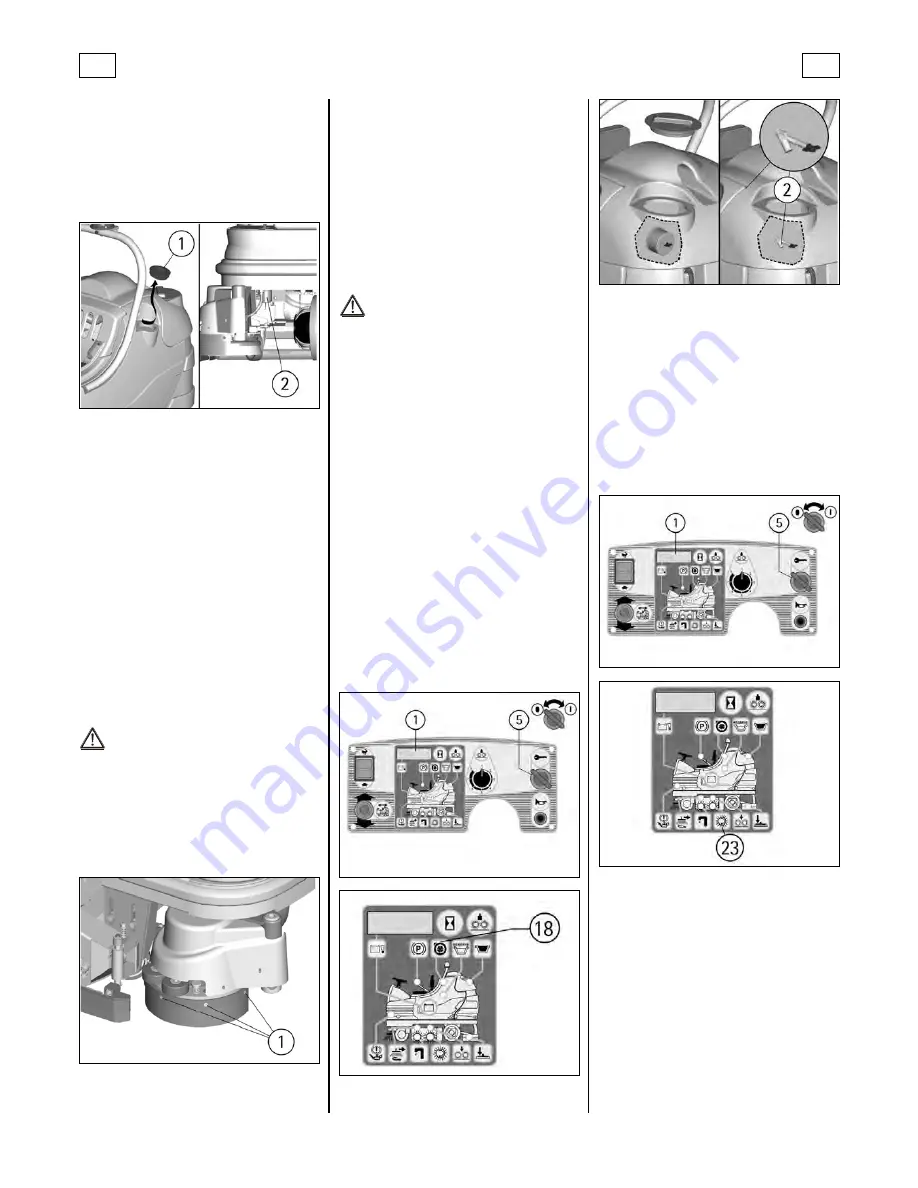

1. Verify that the key switch (5) is positioned clock-

wise to switch on the machine. In presence of alarm

signals it is necessary to switch off and on again the

machine to restore the functionality.

2. Check the charge level of the batteries on the

display (1).

3. Verify of having activated correctly the function

of drying (see under paragraph “STARTING OF THE

MACHINE”).

4. If, both in mode (MAN) as (AUTO), the signal

lamp (18) is on but the suction system does not work,

it is necessary to check the connection of the suction

motor plugs situated in the compartment behind the

seat.

5. The that the recovery tank is not full.

6. Check that the float switch (2) in the recovery

tank is assembled correctly.

If the problem persists, please contact the authorized

technical assistance.

THE BRUSHES MOTOR DOES NOT WORK

1. Verify that the key switch (5) is positioned clock-

wise to switch on the machine. In presence of alarm

signals it is necessary to switch off and on again the

machine to restore the functionality.

2. Check the charge level of the batteries on the

display (1).

3. Verify of having activated correctly the function

of washing with the brushes (see under paragraph

“STARTING OF THE MACHINE”).

4. If, both in mode (MAN) as (AUTO), the signal

lamp (23) is on but the brushes do not turn, please

contact the authorized technical assistance.

If the problem persists, please contact the authorized

technical assistance.

THE TRACTION MOTOR DOES NOT WORK

1. Sit on the guiding place.

2. Verify that the key switch (5) is positioned clock-

wise to switch on the machine. In presence of alarm

signals it is necessary to switch off and on again the

machine to restore the functionality.

3. Check the charge level of the batteries on the

display (1).

4. Check through the signal lamp (17) that the

parking brake is not inserted and eventually release

it (see under paragraph “EMERGENCY-PARKING

BRAKE”).

5. Check that the selector (8) is in the movement

position.

6. Press the accelerator pedal placed on the right

side to start the machine.

If the problem persists, please contact the authorized

technical assistance.