GB

GB

8

3. The batteries charge level indicator is digital and

remains fixed on the display. The battery charge level

starts from 100, which indicates the 100% of the to-

tal charge and decreases from 10 to 10. When the

charge level reaches 20%, the display starts blinking,

so you are about the end of working.

ATTENTION:

After a few seconds of the indication 10% and after

this, the blinking of the four lines, all the functions

stop automatically. With the remaining charge it is

anyhow possible to finish the drying operation be-

fore proceeding to the recharge.

HOUR METER

The machine is equipped with an hour meter located

on the same display (1) of the battery charge level

indicator. Pressing the button (2), the first data indi-

cates the working hours and after a few seconds the

working minutes are shown.

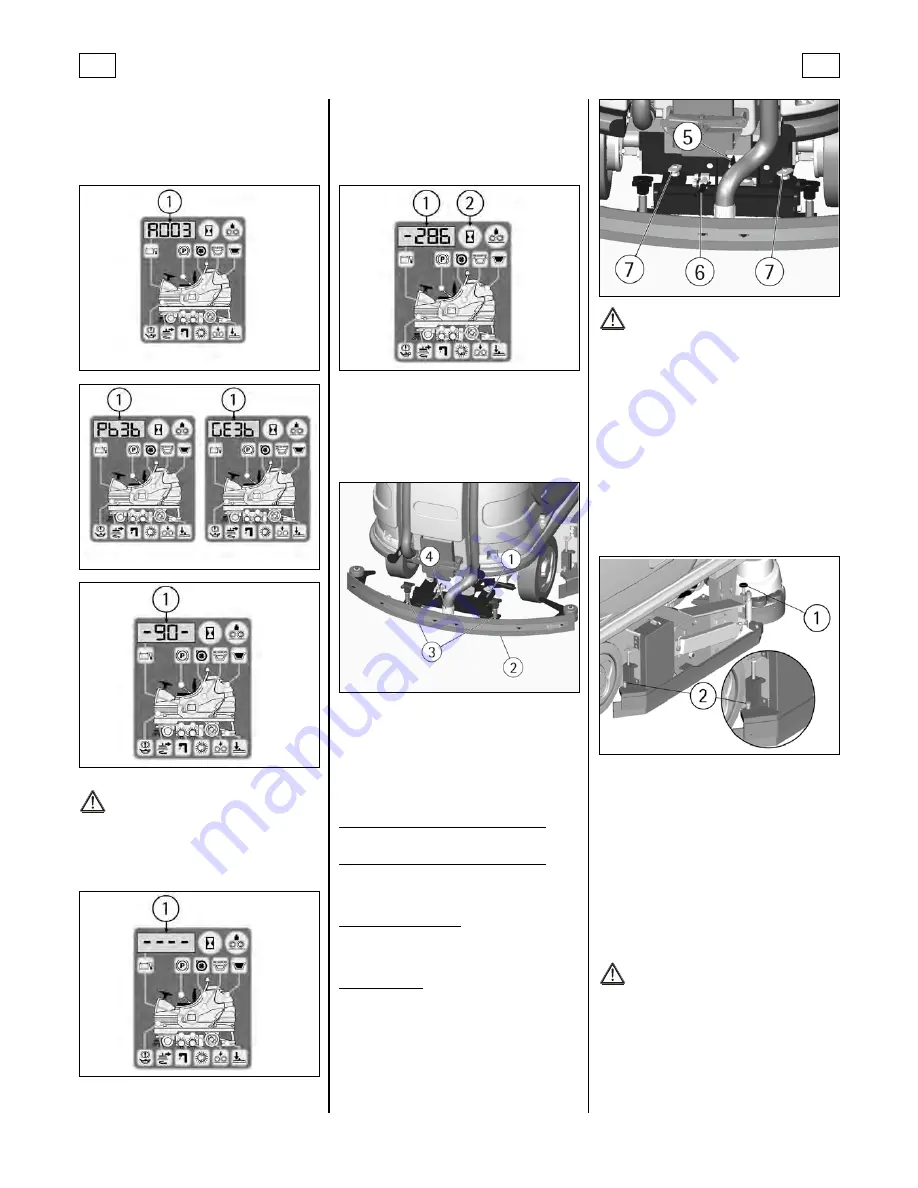

SQUEEGEE ASSEMBLY

1. Insert the two screws (3) situated on the upper

part of the squeegee (2) inside the slots present on

the support.

2. To block the squeegee tighten the stud bolts (3).

3. Insert the squeegee hose (4) into its coupling, re-

specting its position as indicated in the figure.

ADJUSTMENT OF THE SQUEEGEE

In order to have a perfect drying result through the

squeegee, the rear rubber must have the lower bend-

ing uniformly adjusted in all its length. For the ad-

justment, it is necessary to put oneself in working

condition and therefore the suction motor has to be

switched on and the brushes have to function to-

gether with the detergent solution.

The lower part of the rubber is too much bent

Take off the pressure rotating the wing nut (5) coun-

terclockwise.

The lower part of the rubber is not much bent

Increase the pressure rotating the wing nut (5)

clockwise. Check that the wheels which adjust the

height do not rest on the floor, in this case adjust

them as indicated in paragraph "Height adjustment".

The bending is not uniform

Adjust the squeegee inclination rotating counter-

clockwise the wing nut (6) to increase the bending in

the central part, or clockwise to increase the bending

on the extremities.

Height adjustment

Once that the pressure and inclination of the squee-

gee have been adjusted, it is necessary to fix this op-

timum condition making touch slightly the wheels

onto the floor. Rotate clockwise the registers (7) to

lower the wheels or counterclockwise to raise them.

Both wheels must be adjusted in the same measure.

To act upon the register (7) loosen at the same time

the two milled ring nuts, adjust the height acting on

the upper one and then fix the adjustment screwing

and blocking the lower one.

ATTENTION:

Every type of floor requires a specific adjustment.

For example, concrete floors (where the friction re-

sults to be high) need little pressure, while smooth

floors (ceramics) need higher pressure.

If the cleaning operations are made always on the

same type of floor, the adjustment can change only

in function of the rubber wear.

ADJUSTMENT SIDE RUBBERS

To adjust the side rubbers, it is necessary to act upon

the knob (1). Screwing down, more pressure is given

and unscrewing, pressure is being taken off. The rea-

son of the adjustment is to obtain an uniform rubber

bending.

NOTE: If the rubber should lower in the rear part, it

is necessary to restore the correct bending by acting

upon the screw (2).

BRUSHES ASSEMBLY AND DISASSEMBLY

Normally, the machine is delivered with the brushes

assembled.

To assemble and disassemble the brushes:

1. Position the selector (4) for the adjustment of

the brushes pressure on position P1.

2. Activate the machine (see under paragraph

“STARTING OF THE MACHINE”) positioning the selec-

tor (12) to the right to choose the manual mode

(MAN).

3. Activate the selector (14) of up/down of the

brushes base to lower the brushes. Once that it is

lowered, the brushes begin to turn.

4. Turn the key counterclockwise to turn off the

machine.

ATTENTION:

To carry out brushes assembly operations with the

electric supply on, may cause damages to hands.