GB

GB

TROUBLESHOOTING GUIDE

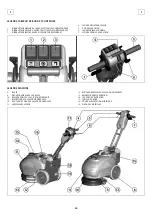

THE SUCTION MOTOR DOES NOT WORK

Verify that the suction motor switch (2) is activated,

checking that its signal lamp is on.

If the problem persists, please contact the authorized

technical assistance.

THE BRUSH MOTOR DOES NOT WORK

1. Verify that the brush motor switch (1) is activat-

ed, checking that its signal lamp is on.

2. Activate the scrub control levers (6).

If the problem persists, please contact the authorized

technical assistance.

INSUFFICIENT WATER ON THE BRUSH

1. Check that the solenoid valve switch (3) is acti-

vated verifying that the signal lamp is on.

2. Check the level of the liquid in the solution tank

(see under “SOLUTION TANK”).

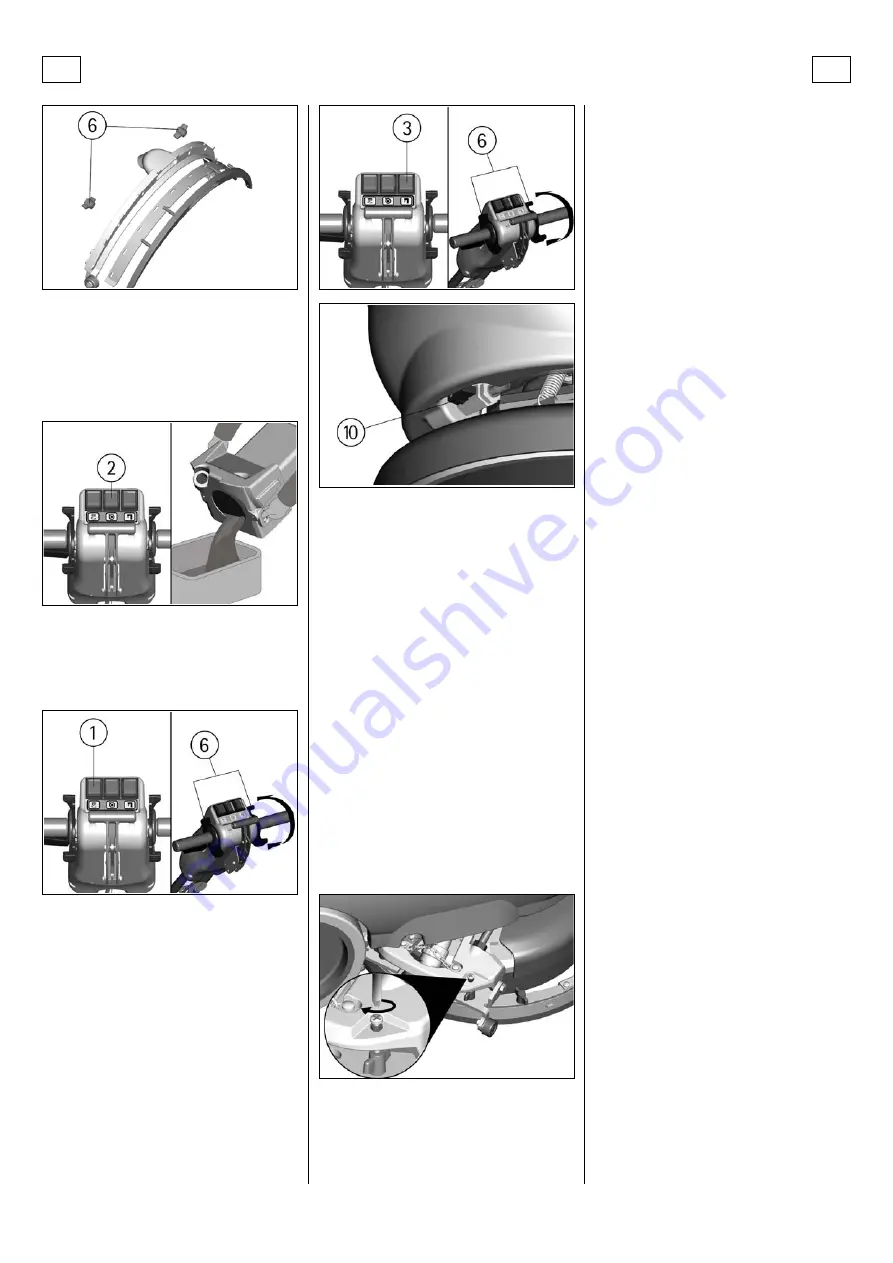

3. Check that the solution flow adjuster (10), placed

in front underneath the solution tank, is sufficiently

open.

4. Press the brush control levers (6).

If the problem persists, please contact the authorized

technical assistance.

THE MACHINE DOES NOT CLEAN PROPERLY

1. The brush does not have the suitable bristle di-

mension: use only original brushes. For advice, con-

tact the authorized technical assistance.

2. The detergent solution is insufficient: open the

solution flow adjuster (10).

3. Check that the liquid detergent is in the recom-

mended percentage.

Contact the authorized technical assistance for ad-

vice.

THE SQUEEGEE DOES NOT DRY PERFECTLY

1. Check that the squeegee rubbers are clean, inte-

gral and not too much worn. If necessary, they need

to be eventually rotated or replaced (see under

“REAR SQUEEGEE RUBBER REPLACEMENT”).

2. Check that the coupling of the suction hose is

correctly inserted in the proper seat on the recovery

tank.

3. Check the suction filter is clean.

4. Replace the rubbers if worn.

5. Check that the suction motor switch is on.

6. Check the level in the recovery tank (see under

“OVERFILL PROTECTION”) and if necessary, empty the

tank.

7. If the floor remains wet in the central part of the

drying, it is necessary to give more pressure in the

rear part of the squeegee, screwing down of some

turns the screw, as shown in the picture.

EXCESSIVE FOAM PRODUCTION

Check that low foam detergent has been used. Add

small quantities of anti foam liquid into the recovery

tank.

Do not use excessive amounts of detergent as even

with low foaming agent, the foam will be created

and lead to vacuum motor damage. Also excessive

detergent will result in solution pipe blockages over

time.

Please be aware that a larger quantity of foam is

produced when the floor is not very dirty. In this ca-

se please dilute detergent solution.

20

Summary of Contents for Baby-e

Page 2: ......