GB

GB

ATTENTION:

When the indication -10- appears blinking, auto-

matically the brushes stop, while the suction contin-

ues to work. When visualizing the four lines blinking,

also the suction will stop automatically. Instead, the

traction system remains functioning to enable the

transfer of the machine to the place provided for the

tank emptying and for the recharge of the batteries.

SETTING OF THE BATTERY CHECK CARD

The setting of the battery check card can be:

GE 24 (check card set for GEL batteries).

or

Pb 24 (check card set for lead batteries).

The machine, if not specified otherwise, is supplied

with the battery check card set for lead batteries. To

modify this setting, it is necessary to:

1. Switch off and on the machine.

2. Immediately after having switched on, when on

the display (1) the writing Pb24 appears, press simul-

taneously the push buttons (3) and (6) up to the

blinking of the writing.

3. When the writing begins to blink, take off the

fingers from the push buttons and press once the

push button (6).

4. The writing GE24 appears blinking.

5. When the writing stops to blink, the setting is

modified.

For the passage of the setting from gel batteries into

lead batteries, repeat the procedure pressing button

(3) instead of button (6).

ATTENTION:

As the machine is a 24V model, do not set the bat-

teries at 36V.

HOUR METER

The machine is equipped with an hour meter located

on the same display (1) of the battery charge level

indicator. Keeping the button (13) pressed, the first

data indicates the working hours and after a few se-

conds the working minutes are shown.

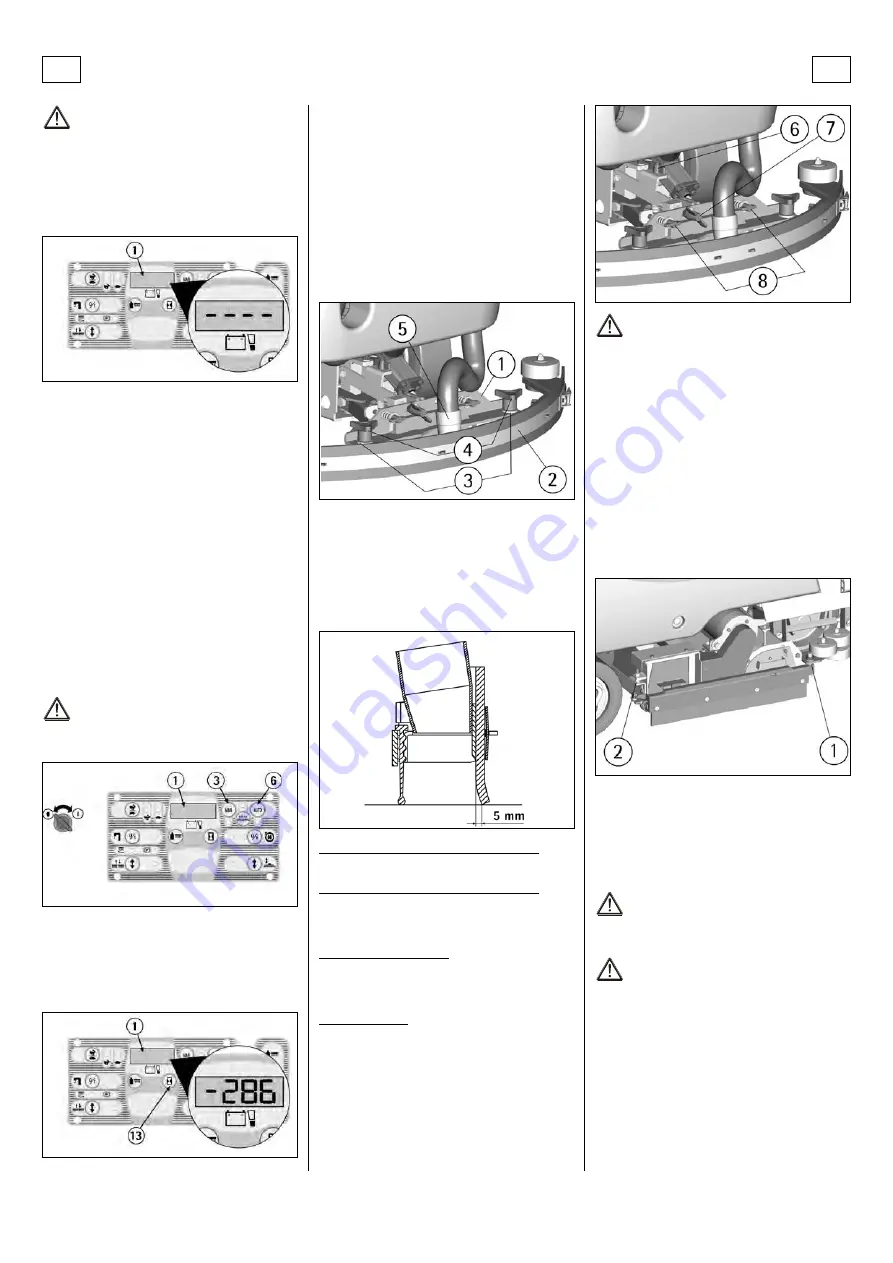

SQUEEGEE ASSEMBLY

1. Maintain the squeegee support (1) slightly lifted

from the floor.

2. Insert the threaded parts of the two knobs (4)

making them slide inside the two slots on the sup-

port placed on the upper part of the squeegee (2).

3. Put the washers (3) into position, they are two

for each knob, so that they are assembled one under

and the other on each of the two slots present on

the support.

4. Block the squeegee by rotating the two knobs (4)

clockwise.

5. Insert the squeegee hose (5) into its coupling, re-

specting its position as indicated in the figure.

ADJUSTMENT OF THE SQUEEGEE

In order to have a perfect drying result through the

squeegee, the rear rubber must have the lower bend-

ing uniformly adjusted in all its length. For the ad-

justment, it is necessary to put oneself in working

condition and therefore the suction motor has to be

switched on and the brushes have to function to-

gether with the detergent solution.

The lower part of the rubber is too much bent

Take off the pressure rotating the wing nut (6) coun-

terclockwise.

The lower part of the rubber is not much bent

Increase the pressure rotating the wing nut (6)

clockwise. Check that the wheels which adjust the

height do not rest on the floor, in this case adjust

them as indicated in paragraph "Height adjustment".

The bending is not uniform

Adjust the squeegee inclination rotating counter-

clockwise the wing nut (7) to increase the bending in

the central part, or clockwise to increase the bending

on the extremities.

Height adjustment

Once that the pressure and inclination of the squee-

gee have been adjusted, it is necessary to fix this op-

timum condition making touch slightly the wheels

onto the floor. Rotate clockwise the registers (8) to

lower the wheels or counterclockwise to raise them.

Both wheels must be adjusted in the same measure.

ATTENTION:

Every type of floor requires a specific adjustment.

For example, concrete floors (where the friction re-

sults to be high) need little pressure, while smooth

floors (ceramics) need higher pressure.

If the cleaning operations are made always on the

same type of floor, the adjustment can change only

in function of the rubber wear.

ADJUSTMENT HEIGHT SIDE RUBBERS

To adjust the side rubbers, it is necessary to act upon

the adjusting screws (1) and (2) after having loos-

ened the upper blocking nuts. Unscrewing, the rub-

ber lowers, while screwing down, the rubber is lifted.

The reason of the adjustment is to obtain an uniform

bending.

Having finished the adjustment, tighten the blocking

nuts to fix the position.

BRUSHES ASSEMBLY AND DISASSEMBLY

Normally, the machine is delivered with the brushes

assembled.

To assemble and disassemble the brushes on both

sides of the machine:

1. Make sure the machine is switched off and with

the brushes base in up position (lifted).

ATTENTION:

To carry out brushes assembly operations with the

electric supply on, may cause damages to hands.

ATTENTION:

This operation must be carried out using gloves to

protect from contact with dangerous solutions.

2. Unblock the bar of the side rubber after having

released the knob (1).

23

Summary of Contents for coral 70s

Page 2: ......