14

WORKING ADJUSTMENTS

Both in automatic as in manual mode, during the first metres check:

1.

that the adjustment of the detergent solution flow is sufficient to

wet the floor uniformly avoiding the leakage of detergent from

the splash guards (see under paragraph “FLOW ADJUSTMENT OF

THE DETERGENT SOLUTION”).

2.

that the squeegee adjustment guarantees a perfect drying result

(see under paragraph “ADJUSTMENT OF THE SQUEEGEE”).

3.

that the brushes pressure permits an efficient washing action in

function of the dirt and the speed (see under paragraph

“ADJUSTMENT OF THE BRUSHES PRESSURE”).

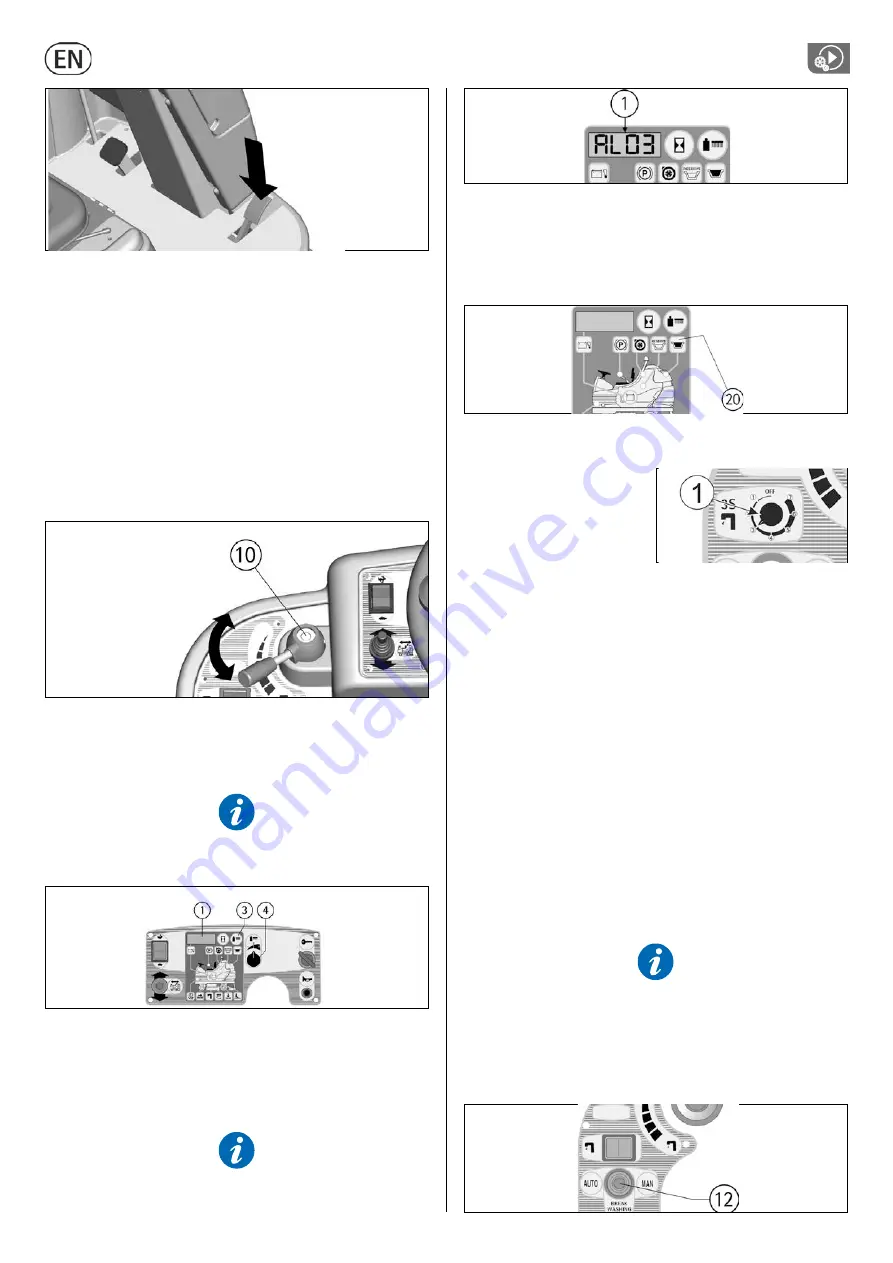

FLOW ADJUSTMENT OF THE DETERGENT SOLUTION

To adjust the detergent solution quantity that flows down onto the

brushes it is necessary to act upon the solution valve knob (10) placed

on the upper part of the side instrument board, rotating

counterclockwise to increase it and clockwise to reduce it up to closure

of the flow.

BRUSHES PRESSURE ADJUSTMENT

Using the knob (4) it is possible to adjust the brushes pressure on the

floor on three preset levels. On the display (1) the pressure previously

set can be seen, by pressing the button (3).

The adjustment is made this way on both manual and automatic mode.

To avoid overloading the brushes motors it is bette to decrease the

brushes pressure when switching from smooth to rough floors (i.e.

concrete floors).

ELECTRIC PROTECTION

The machine is equipped with an electronic system of amperemetric

protection for the principal working functions. This control device

disconnects the function of the interested component that shows the

problem and indicates on the display (1) the corresponding alarm, for

example ”AL01”, “AL03”.

The last two figures indicate the code number of the alarm.

To restore the functioning of the component, turn off and on again the

machine acting upon the key switch. If the alarm persists, please

contact the authorized technical assistance.

OVERFLOW DEVICE

In order to avoid serious damages to the suction motors, the machine is

equipped with a float that intervenes when the recovery tank is full,

closing the suction, the switching on of the signal lamp (20) for the

signaling of the full recovery tank and consequently to the drying stop.

When this happens, it is necessary to empty the recovery tank (see

under paragraph “RECOVERY TANK EMPTYING AND CLEANING”).

SELECTING AND WORKING ON 3S “SOLUTION SAVING SYSTEM”

MODE

To work with the 3S “Solution

Saving System” select a water

carriage using the knob (1).

On manual mode the detergent solution flow is constant and related to

the water carriage selected using the knob.

On automatic mode the carriage of the detergent solution flow changes

accordingly to the speed, up to the maxim set, in order to have a

constant water carriage per square meter.

If the machine is steady then the speed will be zero and no water will

come out.

STOP OF THE MACHINE AFTER CLEANING OPERATION

IN AUTOMATIC OR MANUAL WORKING MODE:

1.

At the end of the washing cycle put the selector (12) into the

central position (BREAK WASHING). In this way automatically the

brushes lift, the solenoid valve shuts down and it is possible to

finish the drying operation.

2.

When the accelerator pedal is released for more than 3 seconds,

the squeegee raises itself and the suction switches off

automatically.

3.

After three seconds, the accelerator can be pressed again, if a

machine's transfer has to be made (the transfer can be carried out

also if the pedal is never lifted, in this case the squeegee gets lifted

and the suction stop automatically after 15 seconds).

4.

Turn the switch key counterclockwise to switch off the machine.

5.

Insert the parking brake (see under paragraph “EMERGENCY-

PARKING BRAKE”).

The mode (BREAK WASHING) is specific for the transfer at the end of

the cleaning operation.

Starting again the cleaning operation:

A.

by positioning to the left the selector (12) into position (AUTO) one

can start again to work in an automatic mode.

B.

by positioning to the right the selector (12) into position (MAN)

the machine re-establishes the functions pre-set manually.