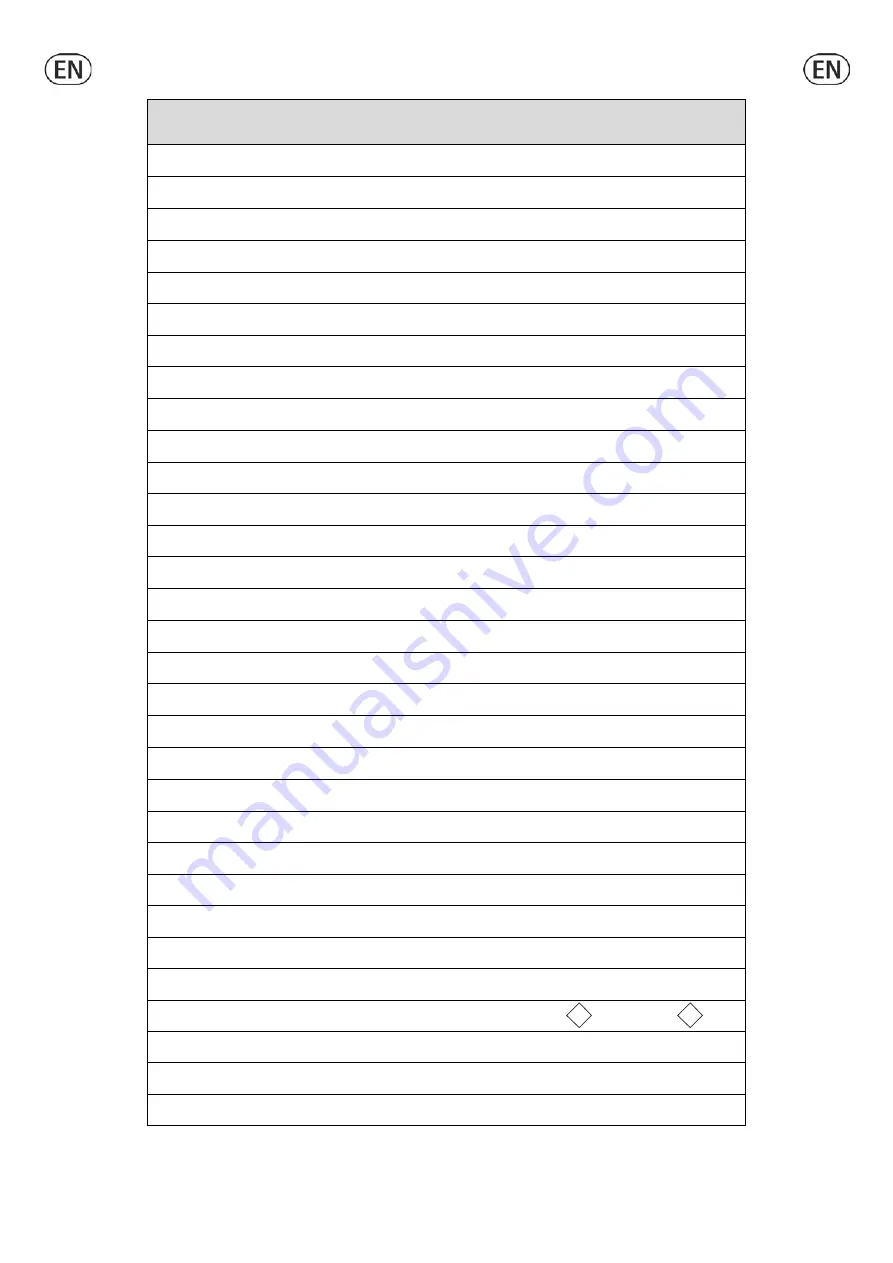

TECHNICAL DESCRIPTION

diamond

100AC

diamond 130

Cleaning width

mm

1000

1300

in

40

51

Squeegee width

mm

1175

1550

in

46

61

Working capacity, up to

m

2

/h

7000

9100

sqft/h

75347

97951

Brushes diameter

mm

2x510

4 x 355

in

2x20

4 x 14

Brushes rpm

rpm

162

220

Pressure on the brushes

kg

160

160

lbs.

353

353

Brushes motor

W

2000

1920

A

56

53

Suction motor

W

2x570

2x570

A

2x16

2x16

Suction vacuum

mbar

190

190

water lift

76

76

Traction motor

W

1200

1400

A

33

39

Type of drive

Autom.

Autom.

Movement speed (max)

km/h

7

7

mph

4.35

4.35

Maximum gradient

%

10

10

Solution tank

l

235

235

gal

62

62

Recovery tank

l

250

250

gal

66

66

Machine length

mm

2025

2025

in

80

80

Machine height without roll-bar

mm

1330

1330

in

53

53

Height with rollbar, without blinking light

mm

1685

1685

in

66

66

Height with rollbar and blinking light

mm

1850

1850

in

73

73

Machine width (without squeegee)

mm

1040

1400

in

41

55

Weight of the machine (empty and without

batteries)

kg

600

600

lbs.

1323

1323

Gross weight of the machine

(in conformity with EN 60335-2-72 art. 5.z102)

kg

1510

1530

lbs.

3329

3373

Battery voltage

V

36

36

Capacity of the batteries

Ah

5

500

500

Weight of the batteries

kg

600

600

lbs.

1323

1323

Battery van (LxPxH)

mm

665x640x530

665x640x530

in

26x25x21

26x25x21

Acoustic pressure level

(in conformity with EN 60704-1) Lpa

dB (A)

<70

<70

Class

Protection level

IP

X3

X3

Packed machine weight

kg

650

650

lbs.

1433

1433

Package dimensions (LxDxH)

cm

213 x 115 x 165

213 x 115 x 165

in

84 x 45 x 65

84 x 45 x 65

III

III