10

2. Connect the terminals, respecting the polarities, avoiding

contact with other parts that could create short circuit.

BATTERIES CHARGE LEVEL INDICATOR

The battery charge level is visualized on the display with its respective

symbol (see "CONTROLS DISPLAY").

When the last segment of charge starts blinking, the

battery is almost low and the suction and brushes

functions are disabled.

When even the last segment of charge turns off, the

battery is completely low and the machine stops.

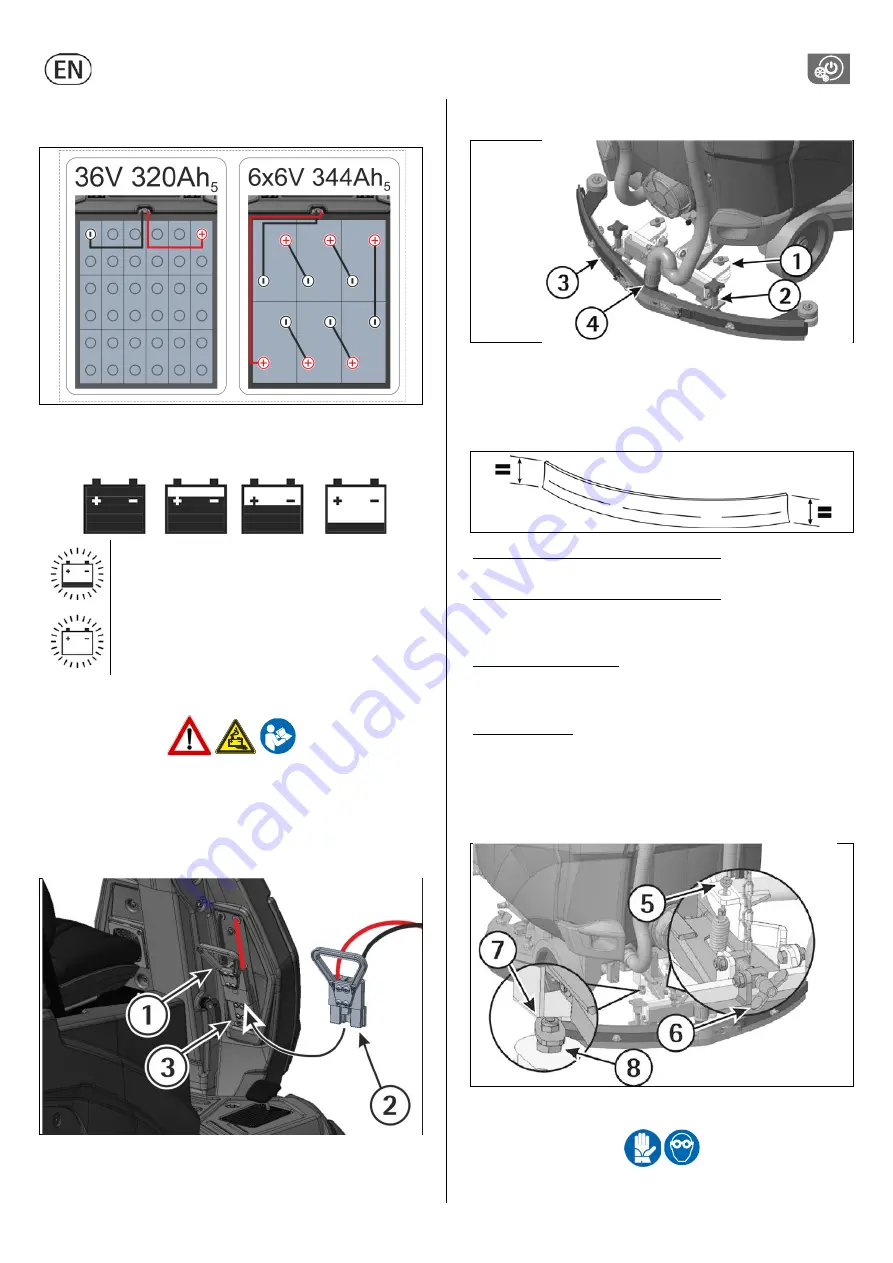

CHARGING THE BATTERIES

1.

Plug the connector (2) of the battery recharger into the battery

connector (1).

2.

Proceed for the recharging.

Once that the battery recharging is completed:

3.

Disconnect the connector of the battery recharger from the

battery connector (1).

4.

Connect instead the machine connector (3).

SQUEEGEE ASSEMBLY

1.

Insert the two stud bolts (2) situated on the upper part of the

squeegee (3) inside the slots present on the support (1).

2.

To block the squeegee, tighten the stud bolts (2).

3.

Insert the squeegee hose (4) into its coupling, respecting its

position as indicated in the figure.

ADJUSTING THE SQUEEGEE

In order to have a perfect drying result through the squeegee, the

rear rubber must have the lower bending uniformly adjusted in all its

length. For the adjustment, it is necessary to put oneself in working

condition and therefore the suction motor has to be switched on and

the brushes have to function together with the detergent solution.

The lower part of the rubber is too much bent

Take off the pressure rotating the wing nut (5) counterclockwise.

The lower part of the rubber is not much bent

Increase the pressure rotating the wing nut (5) clockwise. Check that

the wheels which adjust the height do not rest on the floor, in this

case adjust them as indicated in paragraph "Height adjustment".

The bending is not uniform

Adjust the squeegee inclination rotating counterclockwise the wing

nut (6) to increase the bending in the central part, or clockwise to

increase the bending on the extremities.

Height adjustment

Once that the pressure and inclination of the squeegee have been

adjusted, it is necessary to fix this optimum condition making touch

slightly the wheels onto the floor. Rotate clockwise the registers (7)

to lower the wheels or counterclockwise to raise them. Both wheels

must be adjusted in the same measure. To act upon the register (7)

loosen at the same time the nuts (8), adjust the height then fix the

adjustment by tighten the nuts (8).

ASSEMBLING AND DISASSEMBLING THE SPLASH GUARDS

For the splash guards cleaning, it is necessary to take off the two

metal covers.