21

PROGRAMMED MAINTENANCE

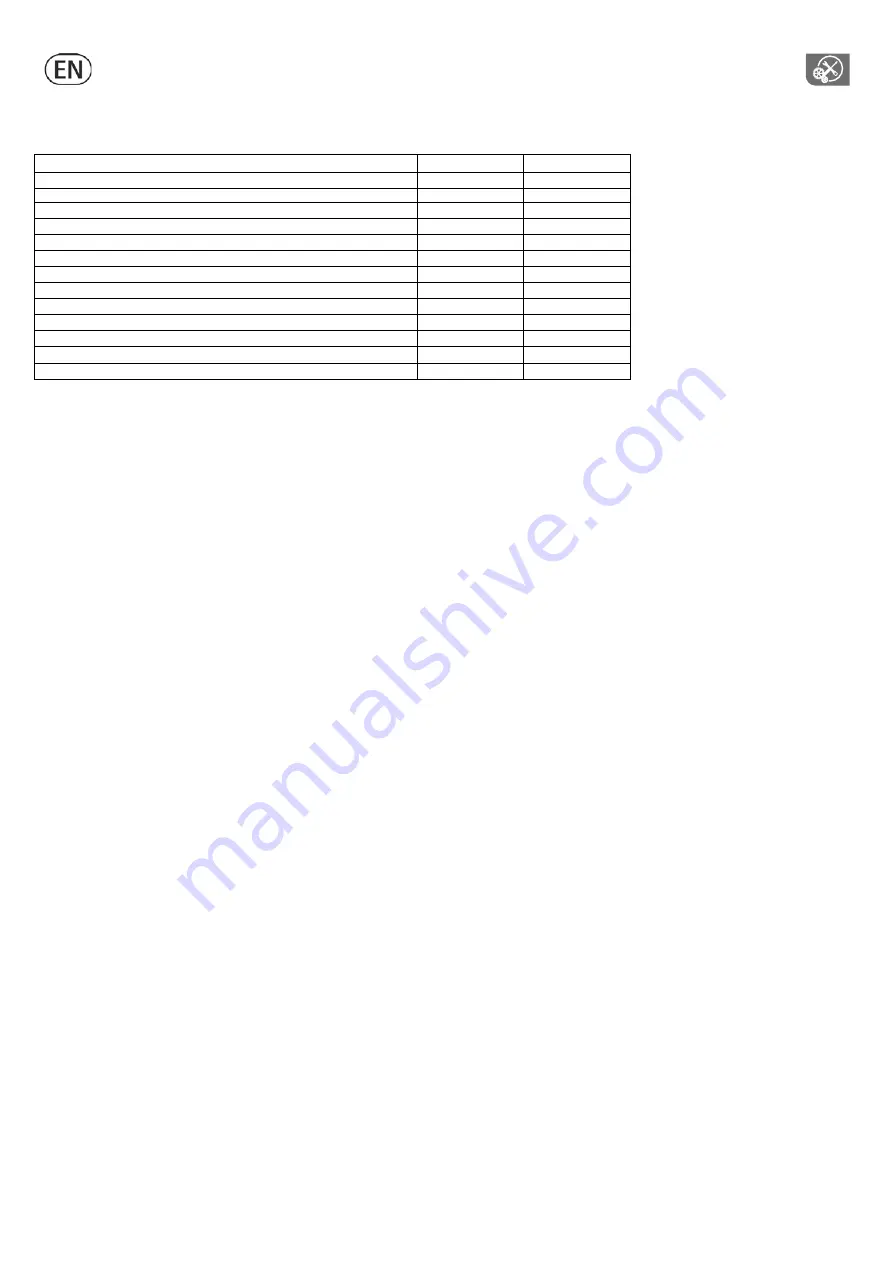

PERIODIC ORDINARY MAINTENANCE CHART

INTERVENTION

DAILY

PERIODIC

RECOVERY TANK CLEANING

•

SUCTION FILTER CLEANING

•

SOLUTION TANK FILTER CLEANING

•

BRUSHES CLEANING

•

BRUSHES DISASSEMBLY AND CLEANING

•

SQUEEGEE CLEANING

•

FRONT SQUEEGEE RUBBER CHECK

•

REAR SQUEEGEE RUBBER CHECK

•

SPLASH GUARD RUBBER CHECK

•

CHECK SQUEEGEE ADJUSTMENT

•

SQUEEGEE HOSE CLEANING

•

SOLUTION TANK CLEANING

•

CHECK BATTERIES ELECTROLYTE

•