User Manual MIC 980

Issue 21.01.2019_01

30

No fault

Chamber symbol is displayed.

Fault or Alarm

alternate

Figure 8: Alarm

Be aware

Chamber sensor defect generally leads to program termination.

11

Information page

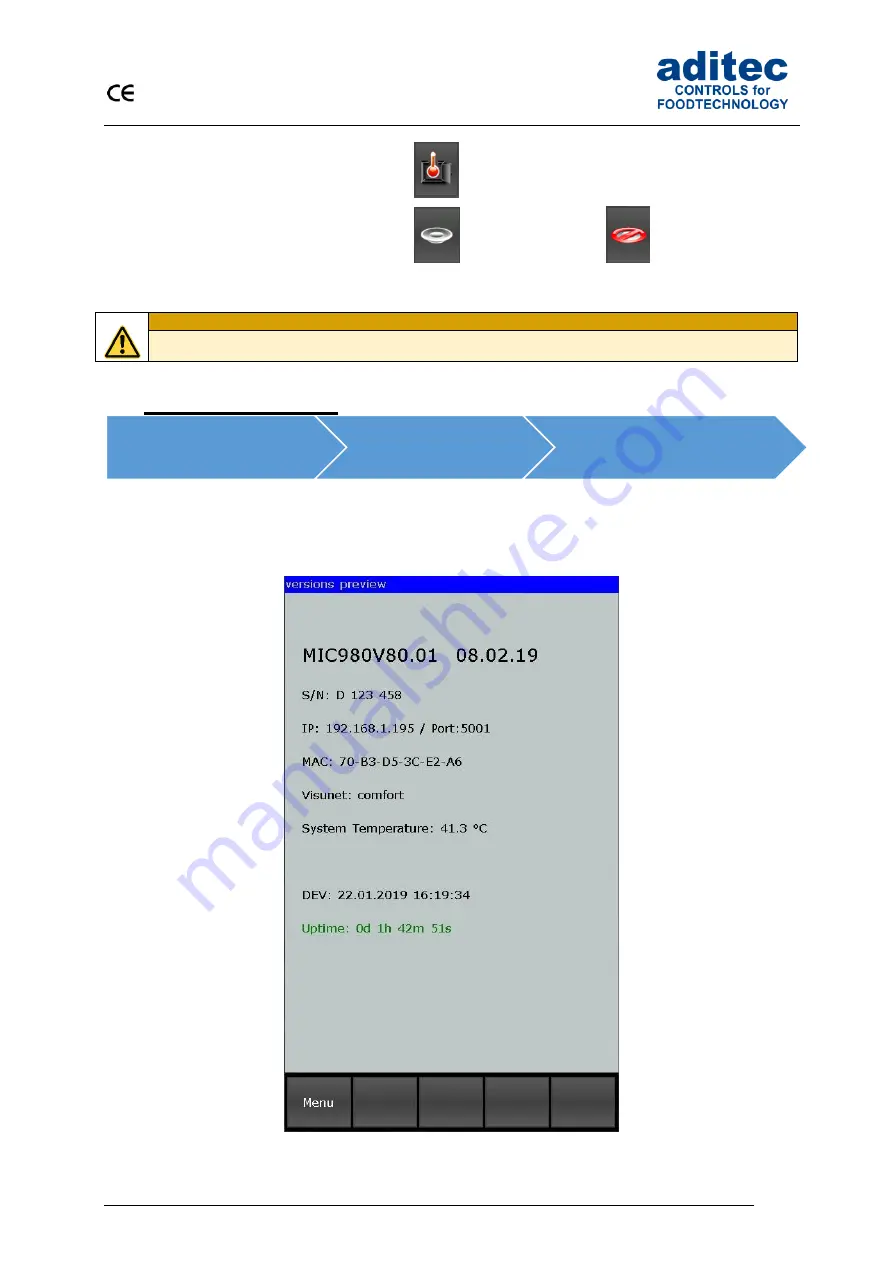

On the info page the following information is shown: which type of device you have got, the software

version, device number, IP number with port, MAC address, VisuNet if enabled and the system

temperature.

Figure 9:

Information page

Standby

Menü

Information