User manual MKA 120

Conforms to

Issue 07.07.2021_01 Page 17

2) The programis paused and th edisply will show the message

„Temperature reached!“, the

„Start/Stop“ button will be flashing. The program will only be resumed when the „Start/Stop“

button is pressed and the step time counter will then start.

Hint

This function is pre-defined by your service technician!

5.10 Working with single step control

(V20.11)

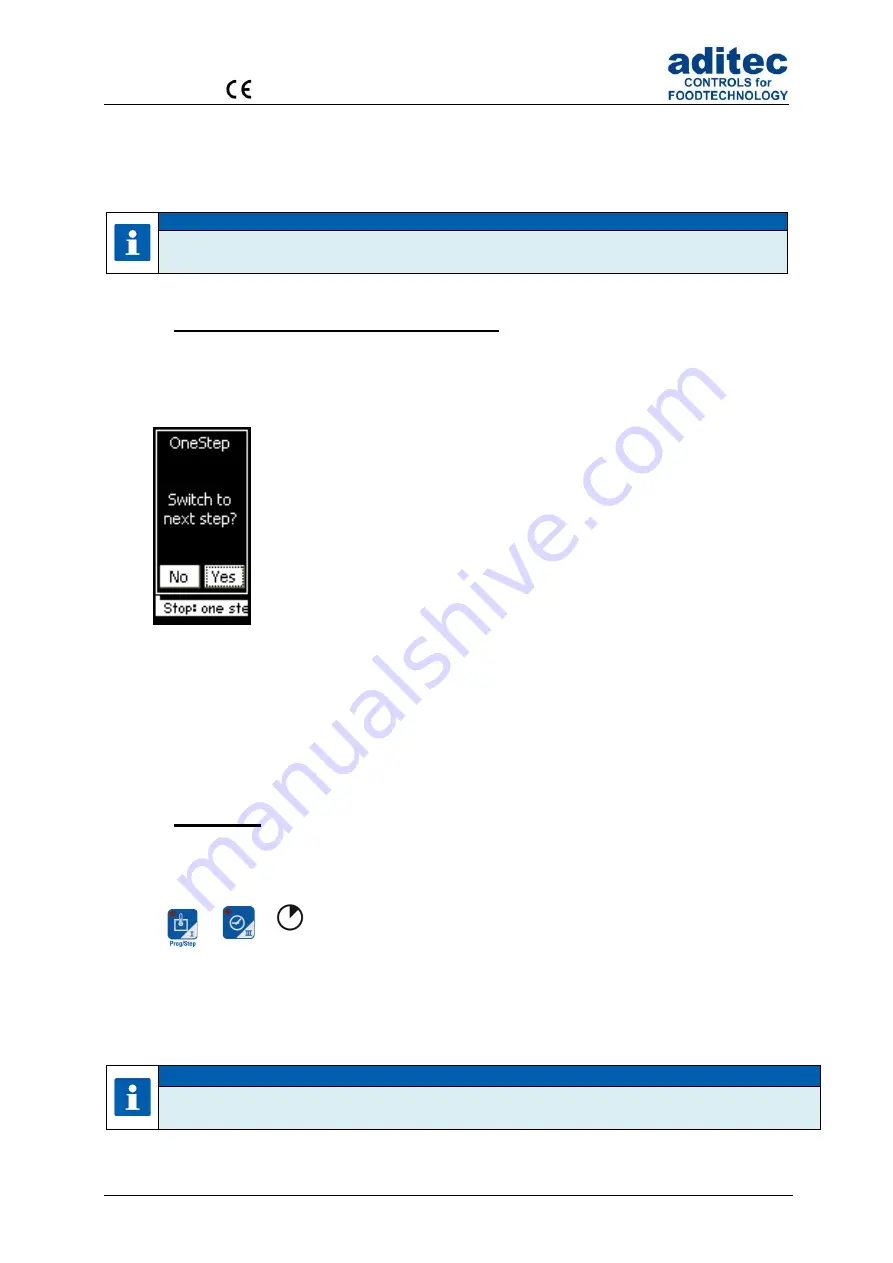

The controller can be configured to pause at the end of every step. The message „Stop: one

step control active“ will be shown and the signal relay will be energised for a pre-programmable

time interval

„Yes “Yes“, controller will switch into the next step (if one exists).

„No“ , message will be hidden, operating screen is shown:

There are 4 options of how to proceed:

1. The program can be switched into the next step manually by the operator who can select

and enter a new step number.

2. The nominal value which triggered the end of the step, e.g. the step time, can be changed

and when you press the „Start/Stop button“ the controller will repeat the paused step.

3.

Change nominal value „Single step control“ to „OFF“ then press the „Start/Stop button“ and

the controller will continue the program with the next step. (if one is pre-programmed).

4.

Press and hold the „Start/Stop button, which will terminate the program immediately.

5.11 Key lock

By locking the keypad, the device is protected against accidental entries.

To activate or deactivate the key lock, a combination of two keys must be pressed for about 3

seconds.

+

When the key lock is activated, the text "KEYLOCK!!!" appears on the display for about 3

seconds.

If you press a key while the key lock is active, the text "KEYLOCK!!!" is also displayed.

If the key lock is deactivated, the text "KEY UNLOCK!" appears on the display for approx. 3

seconds. The controller can be operated normally.

Hint

After a power failure of the control unit, the key lock remains active.

3 sec.