4

Introduction

*Specifications are subject to change without notice.

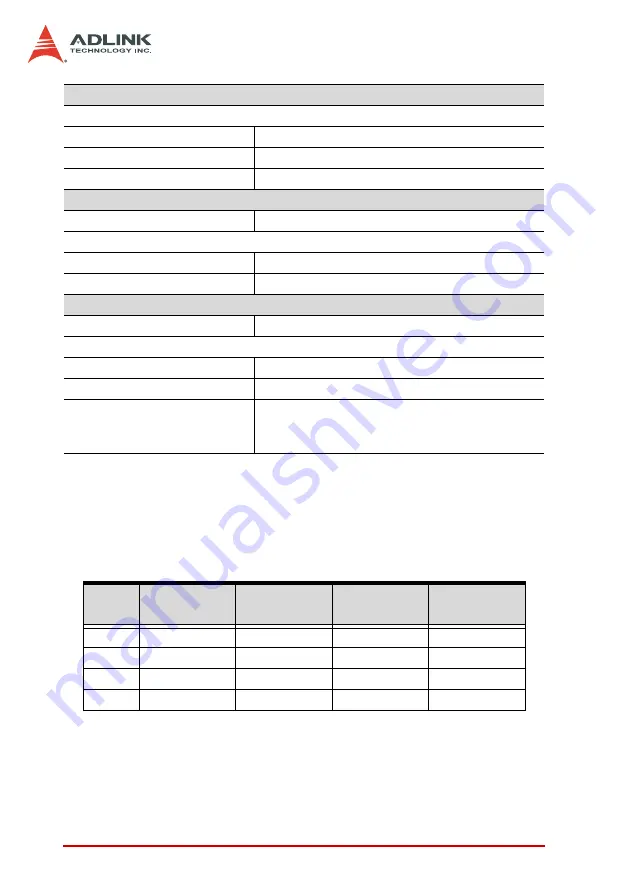

DC Output Table

The combined output power of +5V and +3.3V shall not exceed 35A.

Storage environment

Ambient temperature

PXIS-2508

-20°C to 70°C

PXIS-2558T

0°C to 70°C

Relative humidity

10% to 90%, non-condensing

Shock and vibration

Functional shock

30 G half-sine, 11 ms pulse duration

Random vibration

Operating

5 Hz to 500 Hz, 0.5 Grms, 3 axes

Non-operating

5 Hz to 500 Hz, 2.46 Grms, 3 axes

Certifications

Safety

IEC 61010-1/EN 61010-1

Electromagnetic compatibility

Emissions

EN 55011 Class A

Immunity

EN 61326-1

CE compliance

The PXIS-2508 and PXIS-2558T meet the

essential requirements of applicable European

Directives

1

See DC Output Table below.

2

Measured at operator position, tested in accordance with ISO 7779:1999/

Amd.1:2003(E)

3

Tested in accordance with ISO 7779:1999/Amd.1:2003(E)

VDC

Minimum

Maximum

Load

Regulation

Max. Ripple

& Noise

+5 V

3.0 A

35 A

±5%

50 mV

+12 V

2.0 A

18 A

±5%

120 mV

+3.3 V

1.0 A

20 A

±5%

50 mV

-12 V

0.1 A

2 A

±10%

150 mV

Summary of Contents for 96864-1

Page 11: ......

Page 17: ...6 Introduction ...

Page 20: ...Chassis Overview 9 Rear Panel Figure 2 2 PXIS 2508 2558T Rear Panel Foot stand ...

Page 21: ...10 Chassis Overview Left Panel Figure 2 3 PXIS 2508 2558T Left Panel ...

Page 22: ...Chassis Overview 11 Right Panel Figure 2 4 PXIS 2508 2558T Right Panel ...

Page 23: ...12 Chassis Overview Top Panel Figure 2 5 PXIS 2508 2558T Top Panel ...

Page 24: ...Chassis Overview 13 Base Panel Figure 2 6 PXIS 2508 2558T Base Panel ...

Page 31: ...20 Installation 5 Fasten the screw on the module front panel then con nect all devices ...

Page 41: ...30 Installation ...

Page 53: ...42 Remote Management ...