Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools Needed

•

¼” nut driver

•

Level

•

Screwdriver

•

Adjustable wrench

•

Tape Measure

•

Hammer

•

Sealant

•

UL listed wire nuts

Parts

Needed

Check local codes, check existing electrical supply, and read

“Ductwork Requirements,” and “Electrical Requirements,” before

purchasing parts.

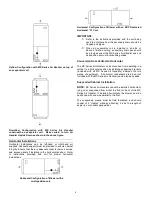

Location Requirements

NOTE:

When the unit is installed in a very humid space and

used in cooling applications, excessive sweating may occur on

outside of unit. To prevent excessive sweating wrap unit with 1”

fiberglass insulation. All openings should be sealed to prevent

air leakage that could cause condensate to form inside the

cabinet.

•

If installed in an unconditioned space, sealant should

be applied around the electrical wires, refrigerant

tubing, and condensate lines where they enter the

cabinet.

•

Electrical wires should be sealed on the inside where

they exit the conduit opening. Sealant is required to

prevent air leakage and from condensate from forming

inside the blower, control box, and on the electrical

controls.

•

The blower and its complementing coil must be

installed in such a way as to allow free access to the

blower/control compartment.

•

The blower and its complementing coil must be

installed with a ¾” drop in the horizontal position

towards the drain pan to ensure proper condensate

drainage. The blower and coil should also be tilted ½”

from back to front toward the drain line.

Installation Clearances

Non-Ducted Return Closet Installation

The blower and coil can be installed in a closet with a false

bottom to form a return air plenum or be installed with a return

air plenum under the coil section.

Louvers or return air grilles are field supplied. Local codes may

limit application of systems without a ducted return to single-

story buildings.

•

For a unit installed in a closet with a louvered return

opening, the minimum open area for the louvers will be

-

320 square inches for 08 models

-

360 square inches for 12 models

-

450 square inches for 16 and 20 models

•

If the free area is not known, assume a 25% free area

for wood or a 75% free area for metal louvers or grilles.

Using the louver dimensions and the 25% or 75%

assumption, determine if the louver open area meets

the minimum open area listed above.

•

If the return air plenum is used, the return air grille

should be immediately in front of the opening in the

plenum to allow for the free flow of return air.

•

When not installed in front of the opening, there must

be adequate clearance around the MX Series Air

Handler to allow for the free flow of return air.

Installation Configurations

For ease in installation, it is best to make any necessary coil

configuration changes before connecting the MX Series Air

Handler to the coil.

Vertical

Installations

Upflow

The blower should be set on top of the coil section being used

and the blower must be supported on the bottom only and set

on solid floor or a field supplied supporting frame.

Downflow

Turn the Air Handler upside down and place the evaporator coil

on top of the blower. Install the two supporting brackets

(support brackets are included with all MX Series Air Handlers)

between the Air Handler and Evaporator Coil to ensure a proper

fit between the two pieces of equipment. The blower must be

supported on the bottom only and set on a solid floor or a field

supplied supporting frame.

For installations of the MX Series Air Handler with hot water

heating in the downflow configuration ensure that there is

sufficient space between the plenum and the Air Handler to

make the hot water piping connections.

Side Return (Hot water applications only)

Cut and remove panel on the non-motor side, as indicated by

perforations.

Attach evaporator coil with sheet metal screws (if using).

Ensure bottom portion of unit is sealed properly to prevent air

leakage.

This can be used in an upflow or downflow position.

SIDE RETURN IS NOT APPROVED FOR USE WITH

ELECTRIC HEAT.

IMPORTANT

The Clean Air Act of 1990 bans the

intentional venting of refrigerant (CFC’s and

HFC’s) as of July 1, 1992. Approved

methods of reclaiming must be followed.

Fines and/or incarceration may be levied for

non-compliance.

3

Summary of Contents for MX Series

Page 20: ......