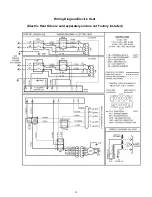

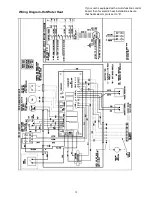

Electrical Requirements

NOTE

: Use copper conductors only.

•

All field wiring must be done in accordance with

National Electrical Code, applicable requirements of

UL and local codes, where applicable.

•

Electrical wiring, disconnect means and over-current

protection are to be supplied by the installer. Refer to

the MX Series Air Handler rating plate for maximum

over-current protection, minimum circuit ampacity, as

well as operating voltage.

•

The power supply must be sized and protected

according to the specifications supplied on the product.

•

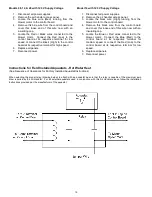

This MX Series Air Handler is factory-configured for

either 240 Volts or 120 Volts, single phase, 60 cycles.

For 208-volt applications, see “208 Volt Conversion” in

the “Make Electrical Connections” section.

•

Refer to the instructions provided with the accessory

for proper installation.

Ductwork Requirements

•

Install the conditioned air plenum, ducts and air filters

(not provided) in accordance with NFPA 90B Standard

for the installation of Warm Air Heating and Air-

Conditioning Systems (latest edition).

•

The MX Series Air Handler is provided with flanges for

the connection of the plenum and ducts.

•

Air filters must be listed as Class 2 furnace air filters

.

•

Supply and return ductwork must be adequately sized

to meet the system’s air requirements and static

pressure capabilities. Ductwork should be insulated

with a minimum of 1” thick insulation with a vapor

barrier in conditioned areas or 2” minimum in

unconditioned areas.

•

Supply plenum should be the same size as the flanged

opening provided around the blower outlet and should

extend ideally at least 3 ft. from the MX Series Air

Handler before turning or branching off plenum into

duct runs. The plenum forms an extension of the

blower housing and minimizes air expansion losses

from the blower.

Installation Instructions

Inspect Shipment

The blower section is completely factory assembled, and all

components are performance tested. Each unit consists of a

blower assembly and controls, in an insulated galvanized steel

factory finished enclosure. Knockouts are provided for electrical

wiring entrance.

1. Check the unit rating plate to confirm

specifications are as ordered.

2. Upon receipt of equipment, thoroughly inspect it

for possible shipping damage. Closely examine

the unit inside the carton if the carton is damaged.

3. If damage is found, it should be noted on the

carrier’s freight bill. Damage claims should be filed

with carrier immediately. Claims of shortages

should be filed with the seller within 5 days.

NOTE:

If any damages are discovered and reported to the

carrier, do not install the unit because your claim may be

denied.

Blower and Coil Assembly

Note:

Read and follow coil installation instructions to

ensure proper installation of refrigerant lines

and drain connections.

Upflow Configuration

1. Ensure the blower section matches the coil being

used.

2. The bottom of the blower section contains a ½”

gasket. Check to make sure gasket is attached to the

bottom of the blower section.

3. Position the blower section over the coil opening or

under the coil depending on your desired

configuration.

4. The MX is designed to fit perfectly with the ADP “C”

depth (20.5”) coil. If “E” depth is used, modify the

duct flange as follows: with the front of the MX and

coil aligned, snip the rear coil flange on each side so

that the MX will sit level on the coil (similar to the

pictures shown in the section “Horizontal

Configuration With Dedicated Horizontal A (HD) Coil.”

5

Summary of Contents for MX Series

Page 20: ......