Call StormTech at

860.529.8188

or

888.892.2694

or visit our website at

www.stormtech.com

for technical and product information.

23

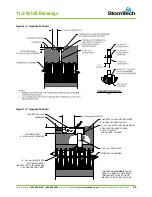

7.0 Inletting the Chambers

The design flexibility of a StormTech chamber system

includes many inletting possibilities. Contact StormTech’s

Technical Service Department for guidance on designing

an inlet system to meet specific site goals.

7.1 TREATMENT TRAIN

A properly designed inlet system can ensure good water

quality, easy inspection and maintenance, and a long

system service life. StormTech recommends a treatment

train approach for inletting an underground stormwater

management system under a typical commercial parking

area. Treatment train is an industry term for a multi-tiered

water quality network. As shown in

Figure 7

, a StormTech

recommended inlet system can inexpensively have tiers of

treatment upstream of the StormTech chambers:

Tier 1 – Pre-treatment (BMP)

Tier 2 - StormTech Isolator

®

Row

Tier 3 - Enhanced Treatment (BMP)

7.2 PRE-TREATMENT (BMP) – TREATMENT TIER 1

In some areas pre-treatment of the stormwater is required

prior to entry into a stormwater system. By treating the

stormwater prior to entry into the system, the service

life of the system can be extended, pollutants such as

hydrocarbons may be captured, and local regulations

met. Pre-treatment options are often described as a Best

Management Practice or simply a BMP.

Pre-treatment devices differ greatly in complexity, design

and effectiveness. Depending on a site’s characteristics

and treatment goals, the simple, least expensive

pretreatment solutions can sometimes be just as effective

as the complex systems. Options include a simple deep

sumped manhole with a 90° bend on its outlet, baffle

boxes, swirl concentrators, and devices that combine

these processes. Some of the most effective pretreatment

options combine engineered site grading with vegetation

such as bio-swales or grassy strips.

Figure 7 - Typical StormTech Treatment Train Inlet System

The type of pretreatment device specified as the first

level of treatment up-stream of a StormTech chamber

system can vary greatly throughout the country and

from site-to-site. It is the responsibility of the design

engineer to understand the water quality requirements

and design a stormwater treatment system that will

satisfy local regulators and follow applicable laws. A

design engineer should apply their understanding of local

weather conditions, site topography, local maintenance

requirements, expected service life, etc. to select an

appropriate stormwater pre-treatment system.

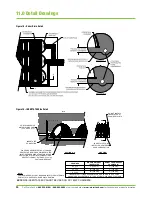

7.3 STORMTECH ISOLATOR ROW – TREATMENT TIER 2

StormTech has a patented technique to inexpensively

enhance Total Suspended Solids (TSS) removal and

provide easy access for inspection and maintenance. The

StormTech Isolator Row is a row of standard StormTech

chambers surrounded with appropriate filter fabrics and

connected to a manhole for easy access. This application

basically creates a filter/detention basin that allows water

to egress through the surrounding filter fabric while

sediment is trapped within. It may be best to think of

the Isolator Row as a first-flush treatment device. First-

Flush is a term typically used to describe the first 1/2” to

1” (13-25 mm) of rainfall or runoff on a site. The majority

of stormwater pollutants are carried in the sediments of

the firstflush, therefore the Isolator Row is an effective

component of a treatment train.

The StormTech Isolator Row should be designed with

a manhole with an overflow weir at its upstream end.

The diversion manhole is multi-purposed. It can provide

access to the Isolator Row for both inspection and

maintenance and acts as a diversion structure. The

manhole is connected to the Isolator Row with a short

length of 8” (200mm) pipe for the SC-160LP chambers,

12” (300 mm) pipe for the SC-310 chamber and 24” (600

mm) pipe for the SC-740 and DC-780 chambers. These

pipes are connected to the Isolator Row with an 8”

(200mm) precored end cap for the SC-160LP, a 12” (300

mm) fabricated end cap for the SC-310 chamber and a

24” (600 mm) fabricated end cap for the SC-740 and DC-

780 chambers. The overflow weir typically has its crest

set between the top of the chamber and its midpoint.

This allows storm water in excess of the Isolator Row’s

storage/conveyance capacity to bypass into the chamber

system through the downstream manifold system.

Specifying and installing proper geotextiles is essential

for efficient operation and to prevent damage to the

system during the JetVac maintenance process. In a

typical configuration, two strips of woven geotextile that

meet AASHTO M288 Class 1 requirements are required

between the chambers and the stone foundation. This

strong filter fabric traps sediments and protects the stone

base during maintenance. A strip of non-woven AASHTO

M288 Class 2 geotextile is draped over the Isolator

chamber row. This 6-8 oz. (217-278 g/m2) nonwoven

STRUCTURE WITH OVERFLOW WEIR

(48” (1200 mm) MIN. DIA. WITH 24” (600 mm)

SUMP RECOMMENDED FOR ACCESS)

OVERFLOW MANIFOLD

ADS 315WTM (OR EQUAL) WOVEN

GEOTEXTILE OVER FOUNDATION

STONE FOR SCOUR PROTECTION

AT ALL CHAMBER INLET ROWS

OPTIONAL PRE-TREATMENT

24” (600 mm) DIA. ACCESS

PIPE REQUIRED

STORMTECH

ISOLATOR ROW

STORMTECH

CHAMBERS

Summary of Contents for StormTech DC-780

Page 2: ...An company TOOL 2 0 DESIGN ...

Page 39: ......