Call StormTech at

860.529.8188

or

888.892.2694

or visit our website at

www.stormtech.com

for technical and product information.

24

7.0 Inletting the Chambers

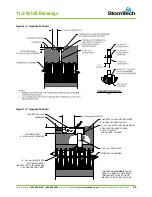

Figure 8 – StormTech Isolator Row Detail

filter fabric prevents sediments from migrating out of the

chamber perforations while allowing modest amounts of

water to flow out of the Isolator Row.

Figure 8

is a detail

of the Isolator Row that shows proper application of the

geotextiles. Contact StormTech for a table of acceptable

geotextiles.

7.4 ENHANCED TREATMENT (BMP) – TREATMENT TIER 3

As regulations have become more stringent, requiring

higher levels of containment removal, water quality

systems may be required to treat higher flow rates,

greater volumes or to provide a higher level of filtration

or other more sophisticated treatment process.

StormTech systems can easily be configured with

enhanced treatment techniques located either upstream

or downstream of the retention or detention chamber

system. Located upstream of an infiltration bed, between

the pretreatment device and the Isolator Row, enhanced

treatment provides a high level of contaminant removal

which protects groundwater or better preserves the

infiltration surface. Located downstream of detention,

enhanced treatment provides a higher level of

contaminant removal prior to discharge to a receiving

body.

Enhanced treatment BMPs are normally applied where

specific regulations and specific water quality product

approvals are in place. StormTech works closely with

providers of enhanced treatment technologies to meet

local requirements.

7.5 TREATMENT TRAIN CONCLUSION

The treatment train is a highly effective water-quality

approach that may not add significant cost to a StormTech

system being installed under commercial parking areas.

The StormTech Isolator Row adds a significant level

of treatment, easy inspection and maintenance, while

maintaining storage volume credit for the cost of a

modest amount of geotextile. Finally where higher levels

of treatment are required, StormTech can integrate other

technologies into the treatment train to provide the most

cost effective treatment approach. This treatment train

concept provides three levels of treatment, inspection and

maintenance upstream and downstream of the StormTech

detention/retention bed.

Inspection is easily accomplished through the upstream

manhole or optional inspection ports. Maintenance of an

Isolator Row is fast and easy using the JetVac process

through the upstream manhole. Section 12.0 explains the

inspection and maintenance process in more detail.

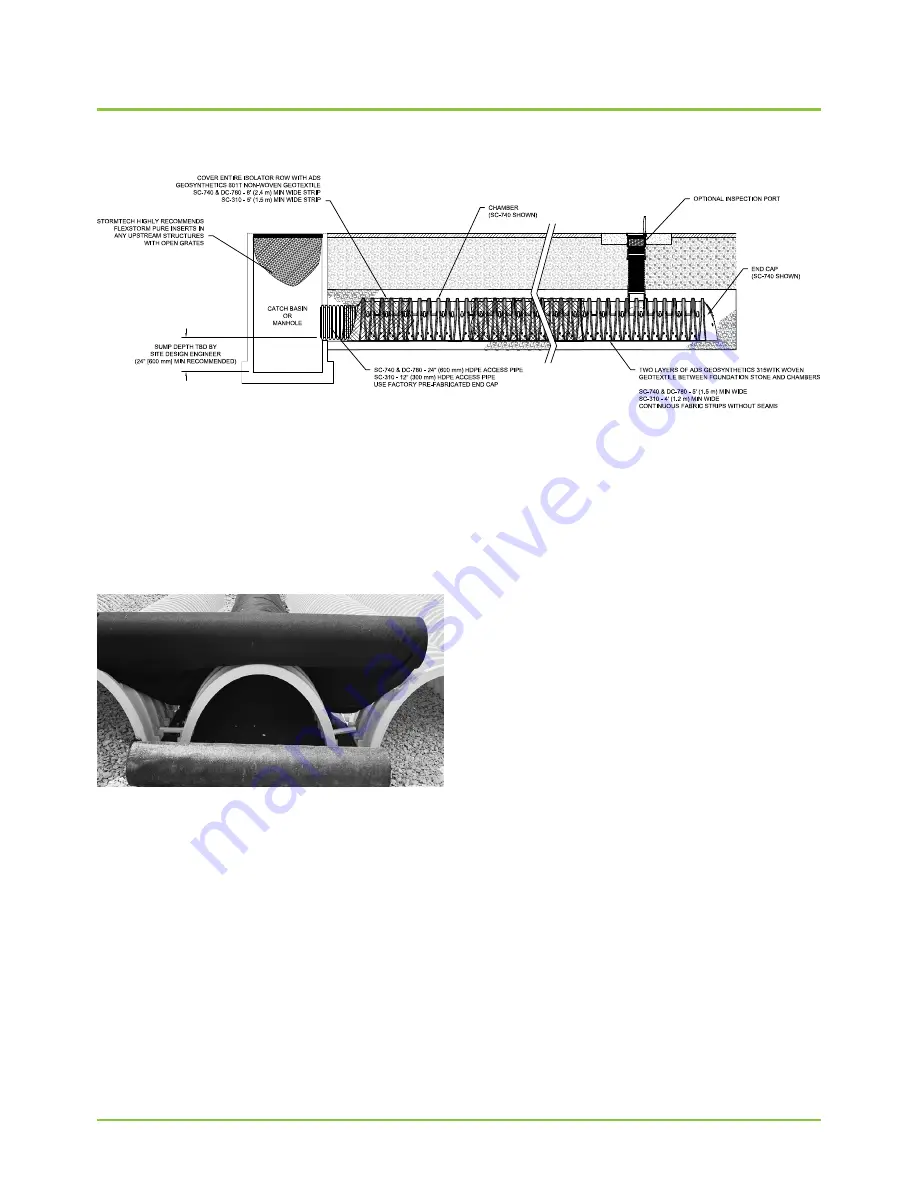

Isolator Rows can be sized to accommodate either

a water quality volume or a water quality flow rate

requirement. The use of filter fabric around the Isolator

Row chambers allows stormwater to egress out of the row

during and between storm events. The rate of egression

for design is dependent upon the chamber model and

sediment accumulation on the geotextile. Contact

StormTech’s Technical Services Department for more

information on Isolator Row sizing.

SC-160LP - 8" (200 mm) HDPE ACCESS PIPE

SC-160LP - 3' (1.0m) MIN WIDE

Note:

Non-woven geotextile over DC-780 Isolator Row chambers is not required.

Summary of Contents for StormTech DC-780

Page 2: ...An company TOOL 2 0 DESIGN ...

Page 39: ......