Call StormTech at

860.529.8188

or

888.892.2694

or visit our website at

www.stormtech.com

for technical and product information.

25

7.0 Inletting the Chambers

7.6 OTHER INLET OPTIONS

While the three-tiered treatment train approach is the

recommended method of inletting StormTech chambers

for typical under-commercial parking applications, there

are other effective inlet methods that may be considered.

For instance, Isolator Rows, while adding an inexpensive

level of confidence, are not always necessary. A header

system with fewer inlets can be designed to further

minimize the cost of a StormTech system. There may be

applications where stormwater pre-treatment may not

be necessary at all and the system can be inlet directly

from the source. Contact StormTech’s Technical Service

Department to discuss inlet options.

7.7 LATERAL FLOW RATES

The embedment stone surrounding the StormTech

chambers allows the rapid conveyance of stormwater

between chamber rows. Stormwater will rise and fall

evenly within a bed of chambers. A single StormTech SC-

740 chamber is able to release or accept stormwater at a

rate of at least 0.5 cfs (14.2 l/s) through the surrounding

stone.

7.8 INLETTING PERPENDICULAR TO A ROW OF

CHAMBERS WITH INSERTA TEE

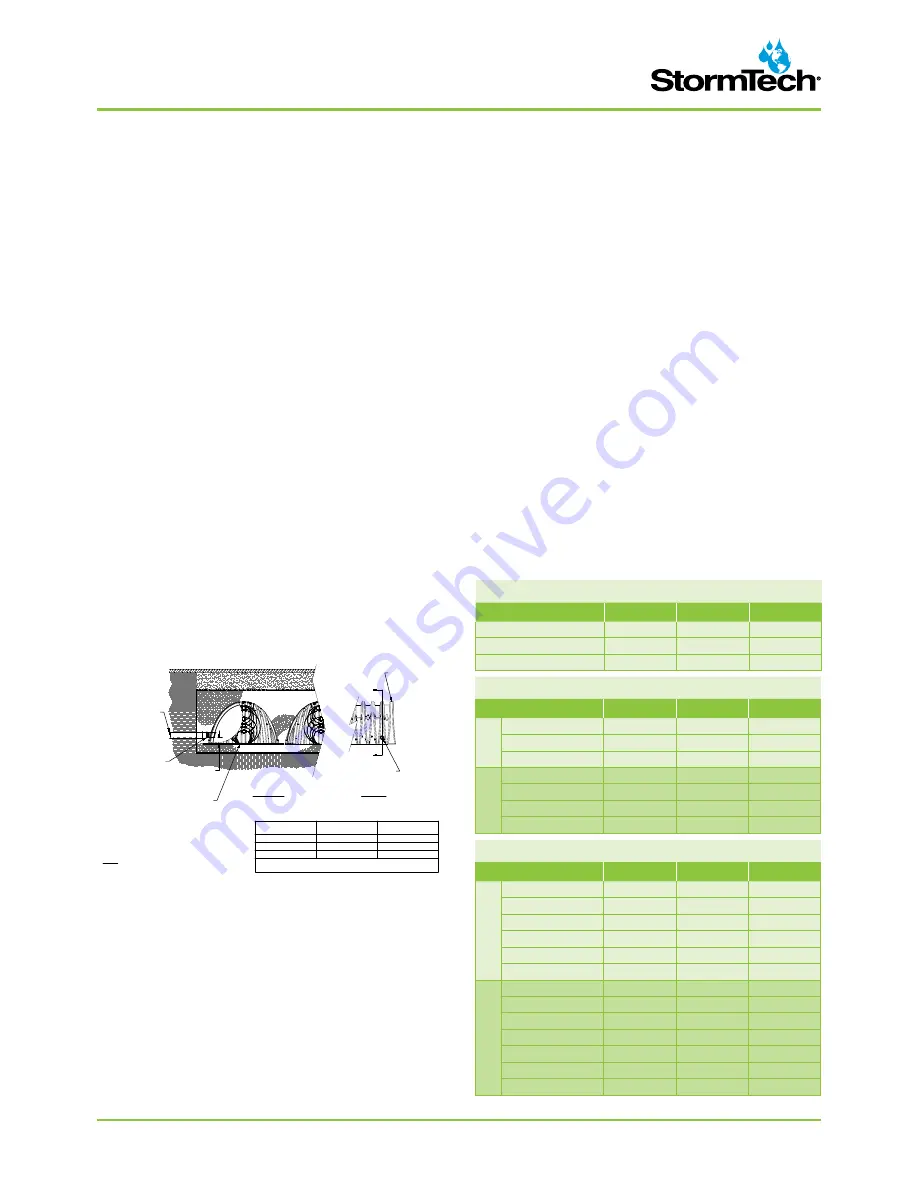

There is an easy, inexpensive method to perpendicularly

inlet a row of chambers. Simply connect the inlet directly

to the chamber with an Inserta Tee. Figure 9 shows a

typical detail along with the standard sizes offered for

each chamber model.

Figure 9 – Inserta Tee Side Detail

Table 9A – Standard Distances from Base of Chamber to

Invert of Inlet and Outlet Manifolds on StormTech End Caps

7.9 MAXIMUM INLET PIPE VELOCITIES TO

PREVENT SCOURING OF THE STONE FOUNDATION

The primary function of the inlet manifold is to convey

and distribute flows to a sufficient number of rows in

the chamber bed such that there is ample conveyance

capacity to pass the peak flows without creating an

unacceptable backwater condition in upstream piping or

scour the foundation stone under the chambers.

Manifolds are connected to the end caps either at the top

or bottom of the end cap. High inlet flow rates from either

connection location produce a shear scour potential of the

NOTE:

SIDe I

NSERTA TEES CANNOT BE USED ON SC-160LP CHAMBERS.

*See StormTech’s Tech Sheet #7 for manifold sizing guidance*

foundation stone. Inlet flows from top inlets also produce

impingement scour potential. Scour potential is reduced

when standing water is present over the foundation

stone. However, for safe design across the wide range of

applications, StormTech assumes minimal standing water

at the time the design flow occurs.

To minimize scour potential, StormTech recommends

the installation of woven scour protection fabric at each

inlet row. This enables a protected transition zone from

the concentrated flow coming out of the inlet pipe to

a uniform flow across the entire width of the chamber

for both top and bottom connections. Allowable flow

rates for design are dependent upon: the elevation of

inlet pipe, foundation stone size and scour protection.

An appropriate scour protection geotextile is installed

from the end cap to at least 10.5’ (3.2 m) for the SC-310,

SC- 740 and DC 780 chambers for both top and bottom

feeding inlet pipes.

See StormTech’s Tech Sheet #7 for guidance on manifold

sizing. ADS’s Technical Services department can also

assist with sizing inlet manifolds for the StormTech

chamber systems.

SC-310 END CAPS

PIPE DIA.

INV. (IN)

INV. (FT)

INV. (MM)

TOP

6” (150 mm)

5.8

0.48

146

8” (200 mm)

3.5

0.29

88

10” (250 mm)

1.4

0.12

37

BO

TTOM

6” (150 mm)

0.5

0.04

12

8” (200 mm)

0.6

0.05

15

10” (250 mm)

0.7

0.06

18

12” (750 mm)

0.9

0.08

24

SC-160LP END CAPS

PIPE DIA.

INV. (IN)

INV. (FT)

INV. (MM)

6" (150mm)

0.66

0.05

16

8" (200mm)

0.80

0.07

20

8" (200mm) Cored

0.96

0.08

24

SC-740 / DC-780 ENDCAPS

PIPE DIA.

INV. (IN)

INV. (FT)

INV. (MM)

TOP

6” (150 mm)

18.5

1.54

469

8” (200 mm)

16.5

1.38

421

10” (250 mm)

14.5

1.21

369

12” (300 mm)

12.5

1.04

317

15” (375 mm)

9

0.75

229

18” (450 mm)

5

0.42

128

BO

TTOM

6” (150 mm)

0.5

0.04

12

8” (200 mm)

0.6

0.05

15

10” (250 mm)

0.7

0.06

18

12” (750 mm)

1.2

0.10

30

15” (900 mm)

1.3

0.11

34

18” (1050 mm)

1.6

0.13

40

24” (1200 mm)

0.1

0.01

3

INSERTA TEE DETAIL

NTS

INSERTA TEE

CONNECTION

CONVEYANCE PIPE

MATERIAL MAY VARY

(PVC, HDPE, ETC.)

PLACE ADS GEOSYNTHETICS 315 WOVEN

GEOTEXTILE (CENTERED ON INSERTA-TEE

INLET) OVER BEDDING STONE FOR SCOUR

PROTECTION AT SIDE INLET CONNECTIONS.

GEOTEXTILE MUST EXTEND 6" (150 mm)

PAST CHAMBER FOOT

INSERTA TEE TO BE

INSTALLED, CENTERED

OVER CORRUGATION

SIDE VIEW

SECTION A-A

A

A

DO NOT INSTALL

INSERTA-TEE AT

CHAMBER JOINTS

NOTE:

PART NUMBERS WILL VARY BASED ON INLET PIPE MATERIALS.

CONTACT STORMTECH FOR MORE INFORMATION.

CHAMBER

MAX DIAMETER OF

INSERTA TEE

HEIGHT FROM BASE OF

CHAMBER (X)

SC-310

6" (150 mm)

4" (100 mm)

SC-740

10" (250 mm)

4" (100 mm)

DC-780

10" (250 mm)

4" (100 mm)

INSERTA TEE FITTINGS AVAILABLE FOR SDR 26, SDR 35, SCH 40 IPS

GASKETED & SOLVENT WELD, N-12, HP STORM, C-900 OR DUCTILE IRON

(X)

Summary of Contents for StormTech DC-780

Page 2: ...An company TOOL 2 0 DESIGN ...

Page 39: ......