Call StormTech at

860.529.8188

or

888.892.2694

or visit our website at

www.stormtech.com

for technical and product information.

32

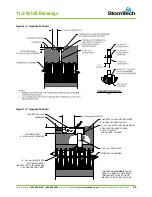

12.0 Inspection & Maintenance

12.3 ECCENTRIC PIPE HEADER INSPECTION

Theses guidelines do not supercede a pipe

manufacturer’s recommended I&M procedures. Consult

with the manufacturer of the pipe header system for

specific I&M procedures. Inspection of the header system

should be carried out quarterly. On sites which generate

higher levels of sediment more frequent inspections may

be necessary. Headers may be accessed through risers,

access ports or manholes. Measurement of sediment

may be taken with a stadia rod or similar device. Cleanout

of sediment should occur when the sediment volume

has reduced the storage area by 25% or the depth of

sediment has reached approximately 25% of the diameter

of the structure.

12.4 ECCENTRIC PIPE MANIFOLD MAINTENANCE

Cleanout of accumulated material should be

accomplished by vacuum pumping the material from the

header. Cleanout should be accomplished during dry

weather. Care should be taken to avoid flushing sediments

out through the outlet pipes and into the chamber rows.

Eccentric Header Step-by-Step Maintenance

Procedures

1. Locate manholes connected to the manifold system

2.

Remove grates or covers

3.

Using a stadia rod, measure the depth of sediment

4.

If sediment is at a depth of about 25% pipe volume or

25% pipe diameter proceed to step 5. If not proceed

to step 6.

5. Vacuum pump the sediment. Do not flush sediment

out inlet pipes.

6. Replace grates and covers

7. Record depth and date and schedule next inspection

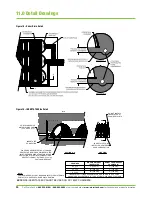

STORMTECH ISOLATOR™ ROW - STEP-BY-STEP

MAINTENANCE PROCEDURES

Step 1)

Inspect Isolator Row for sediment

A) Inspection ports (if present)

i. Remove lid from floor box frame

ii. Remove cap from inspection riser

iii. Using a flashlight and stadia rod, measure

depth of sediment

iv. If sediment is at, or above, 3” (76 mm) depth

proceed to Step 2. If not proceed to Step 3.

B) All Isolator Rows

i. Remove cover from manhole at upstream

end of Isolator Row

ii. Using a flashlight, inspect down Isolator

Row through outlet pipe

1. Follow OSHA regulations for confined

space entry if entering manhole

2. Mirrors on poles or cameras may be used

to avoid a confined space entry

iii. If sediment is at or above the lower row of

sidewall holes [approximately 3” (76 mm)]

proceed to Step 2. If not proceed to Step 3.

Step 2)

Clean out Isolator Row using the JetVac process

A) A fixed floor cleaning nozzle with rear facing

nozzle spread of 45” (1143 mm) or more is

preferable

B) Apply multiple passes of JetVac until

backflush water is clean

C) Vacuum manhole sump as required during

jetting

Step 3)

Replace all caps, lids and covers

Step 4)

Inspect and clean catch basins and manholes

upstream of the StormTech system following local

guidelines.

Figure 20 – StormTech Isolator Row (not to scale)

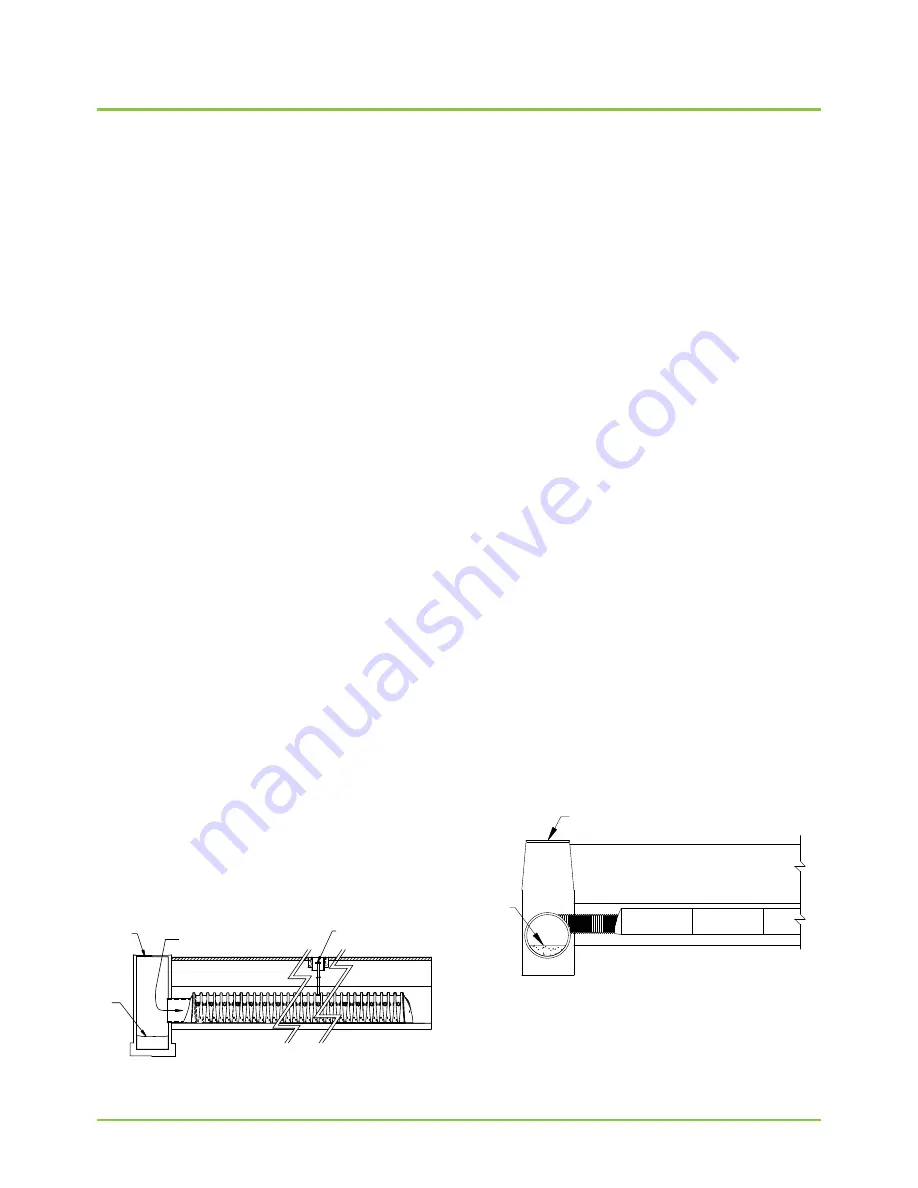

Figure 21 – Eccentric Manifold Maintenance

4

2

1) B)

1) A)

1, 2, 6

3, 4, 5

Please contact StormTech’s Technical Services

Department at 888-892-2894 for a spreadsheet to

estimate cleaning intervals.

Summary of Contents for StormTech DC-780

Page 2: ...An company TOOL 2 0 DESIGN ...

Page 39: ......