Rubber Scratch Force

displays and sets the down force used during tangential emulation.

This is primarily used when cutting thick materials such as sandblast rubber. Tangential emulation

simulates a tangential or servo controlled rotating knife by moving to a position short of the vector

to be cut and putting the knife blade down with a very light force while moving toward the

direction of cut to align the knife before applying the full cutting force. This improves the cut

quality in thick materials. (default 0.1%).

Rubber Backup Multiplier

(default 20) displays and sets the distance the knife will be dragged

at the light force used to align it. This parameter is used with and is additive to the

Rubber

Backup Offset

(default 0.001)

. The Rubber Backup Multiplier is based on the change of angle

between vectors and the Rubber Backup Offset is a constant added to the distance calculated based

on angle. Amount of backup to align knife is angle between vectors in radians * mult

offset.

Max Motion Vector Length

(default 0.001) (Named after the driver that outputs very small

vectors) Allen Cutters very accurately replicate the vectors in the HPGL plot file. Some design

programs output vectors that are very short. It is sometimes desirable to combine some of these

vectors into a longer vector to eliminate jagged edges or slow cutting. This parameter works like a

curve-smoothing algorithm and is used to improve poor HPGL files.

Anticipation Rubber

(

default 0.001)

and Anticipation Vinyl

(default 0.0004) is a parameter

that adjusts the backlash compensation in the cutter. The Anticipation Rubber is the parameter

used when the cutter is in tangential emulation mode and the Anticipation Vinyl is the parameter

used when not in tangential emulation mode. Heavier materials require more backlash

compensation. These numbers are individually set at the factory and should not require adjustment

except when cutting heavy materials. If you are experiencing thick and thin lines or misshaped

letters, adjust the anticipation parameter to obtain satisfactory results.

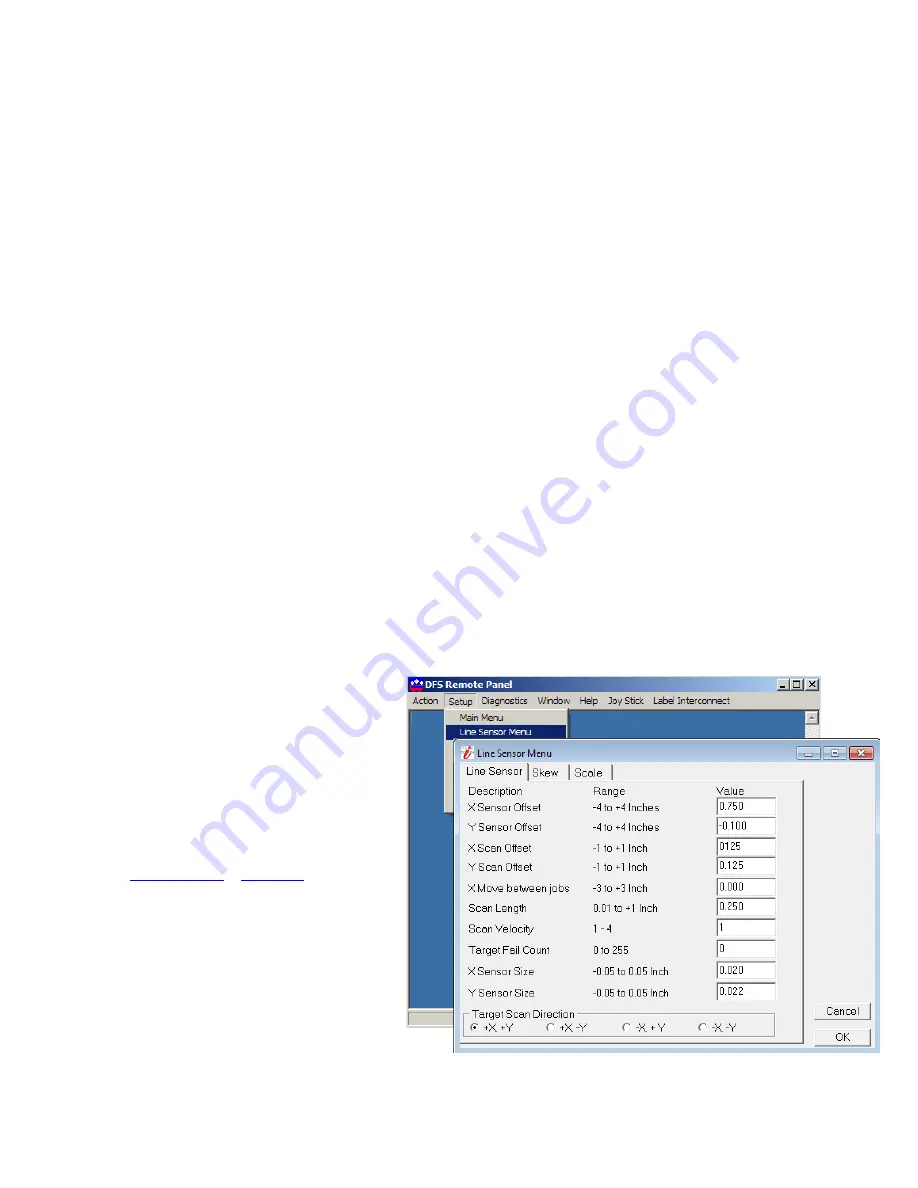

Line Sensor

Clicking on Setup Line Sensor menu opens the SmartMark

TM

Menu.

Sensor Offsets

- The SmartMark

sensor is offset from the center of the

knife. The sensor offset distance is

preset at the factory or during

installation, but may need to be

adjusted on occasion. The i-TECH can

automatically calculate and set the

SmartMark

offset and sensor size

parameters. See drawing for definition

of sensor offsets. Title: Calibration

Sensor size

is the offset from the

exact center of the red dot of the

SmartMark

sensor to the sense radius

and may change based on sensor

sensitivity or media reflectivity. This

parameter is best set using the

procedure in the above TSB. The

Sensor Size parameter is only useful in origin

scale and three target scanning. If you are not,

18