C N C 4 2 2 0 M a c hi ne Too l Op e ra t ion an d Te st

21

2.3

Emergency operation

During the processing, due to user programming, operation and product failures, certain

unexpected events may occur. At this moment, please stop the system immediately. This section

involves the treatment that the system can perform under emergency conditions. Please refer to the

instructions of machine tool for the treatment that the machine tool can perform under emergency

conditions.

2.4

Reset

When the system output or coordinates action is abnormal, press the Reset

key to reset the

system:

1. The motion of all axes stops;

2. M, S function output is invalid (it is possible to set whether disable main axis

positive/negative rotation, lubricant and cooling signals automatically after pressing the

Reset key

);

3. Automatic running stops, and mode function and state maintain.

2.5

Emergency stop

When the machine tool is running, press the Emergency stop button (when external emergency

stop signal is valid) if there is any danger or emergency, and the system will enter the emergency

stop state immediately. At this moment, the machine tool stops moving immediately, and all

outputs (e.g. rotation of main axis, cooling liquid, etc.) are off. Release the button to relieve the

alarm, and then the system enters reset state.

Note 1: Please make sure that the failure has been eliminated before relieving the alarm;

Note 2: Before turning on/off the machine, press the emergency stop button to reduce the electric

impact to the equipment;

Note 3: After relieving the alarm, please re-execute the mechanical reset operation to ensure the

accuracy of the coordinates (if the machine tool doesn’t have mechanical origin, do not perform this

operation);

The emergency stop function is controlled by system parameters ---- emergency stop function. The

function is valid only when the value is set to 1.

The level of emergency stop signal is controlled and set by system parameters ---- emergency stop

signal level.

2.6

Feeding maintaining

When the machine tool is running, press the Pause key

to hold the running. Please note

that the running can’t be stopped immediately during screw thread cutting and circle instruction

running.

2.7

Cutting off power supply

If any danger or emergency occurs when the machine tool is running, please cut off the power

supply immediately to prevent accidents. Please note that the system coordinates may be

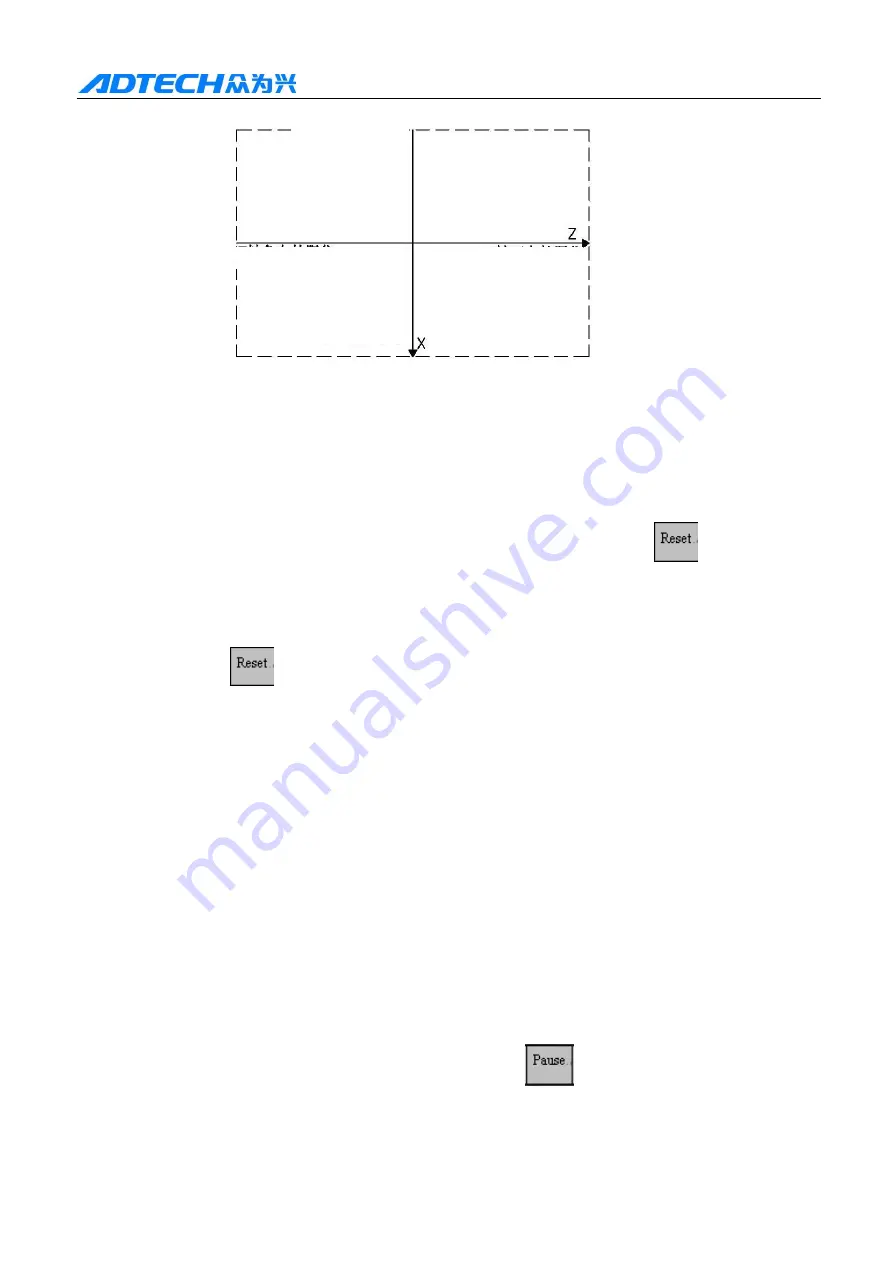

Axis X negative soft limit

Axis Z negative soft limit Axis Z positive soft limit

Axis X positive soft limit