C N C 4 2 2 0 M a c hi ne Too l Op e ra t ion an d Te st

37

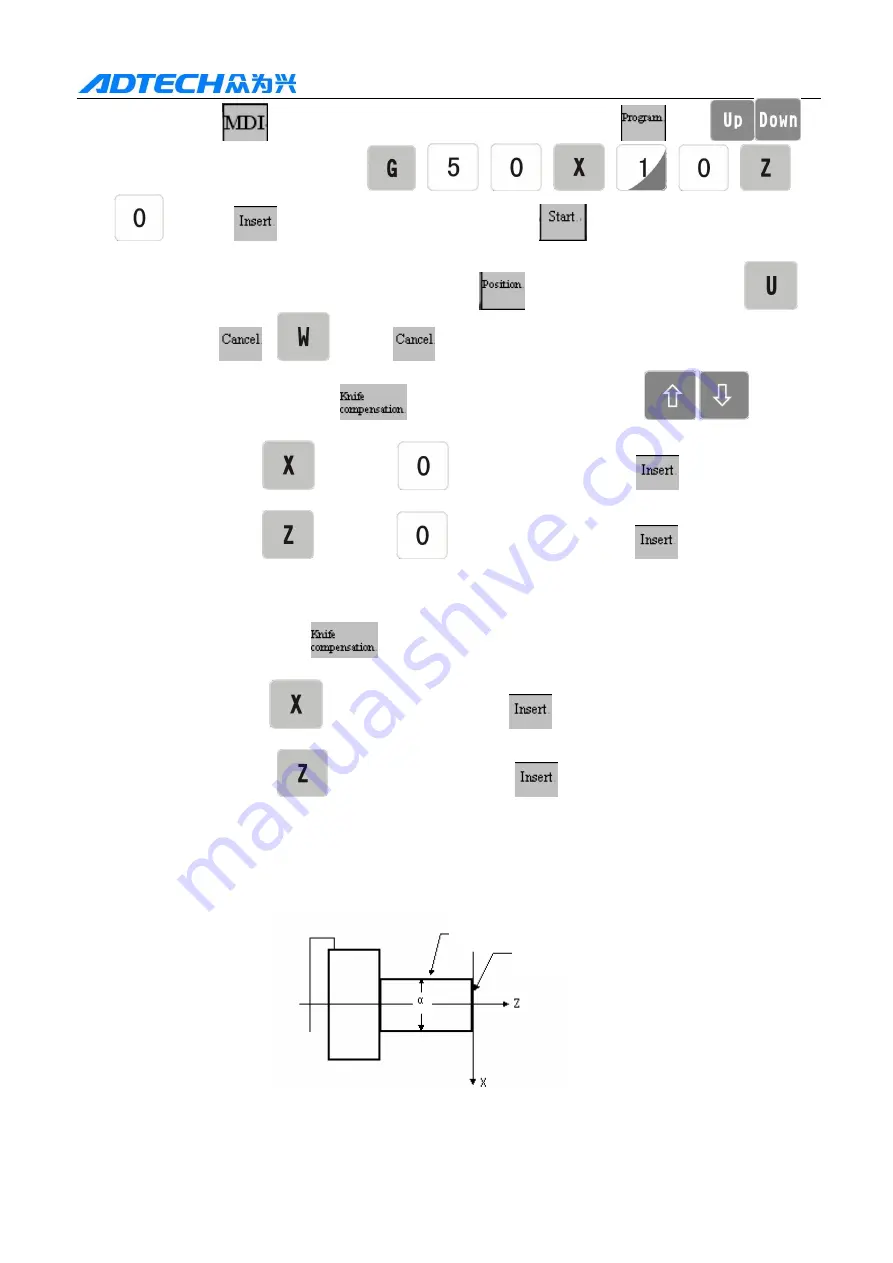

3) Press the MDI

key to enter the MDI mode, and press the Program key

(press

if

necessary) to enter the MDI page; type

,

,

,

,

,

,

,

and Insert

key in sequence, and then press the Start

key to set the actual values of axis

X and Z to the value to work piece coordinates

4) Clear the relative coordinates (U, W) (press the Position

→ turn page to relative position →

→

Cancel

→

→ Cancel

);

4) Press the Knife compensation key

to enter the bias interface, press the

/

key to

move cursor to select the corresponding bias number of the reference knife;

5) Press the address key

, number key

, and then press the Insert key

to set the bias of axis

X of reference knife to 0;

6) Press the address key

, number key

, and then press the Insert key

to set the bias of axis

Z of reference knife to 0;

7) Move the knife to safe position, select another knife (set the bias number in the knife to 0) and move to the

alignment point, as Fig. B;

8) Press the knife compensation

key, and move the cursor to select the corresponding bias number of

the knife;

9) Press the address key

and then press the Insert key

to set the knife compensation value of

axis X to the corresponding bias number;

10) Press the address key

and then press the Insert key

to set the knife compensation value of

axis Z to the corresponding bias number;

11) Repeat step 7~10 to align other knives.

7.2.

Test cutting knife alignment

The test cutting knife alignment is valid if the system parameter 45 is 1. The operation follows

(create work piece coordinates with surfaces of the work piece):

1) Select knife 1 as the reference to make the knife cut along surface A;

2) Take out the knife along axis X when axis Z is still, and stop the rotation of main axis;

Surface B

Surface A