C N C 4 2 2 0 M a c hi ne Too l Op e ra t ion an d Te st

40

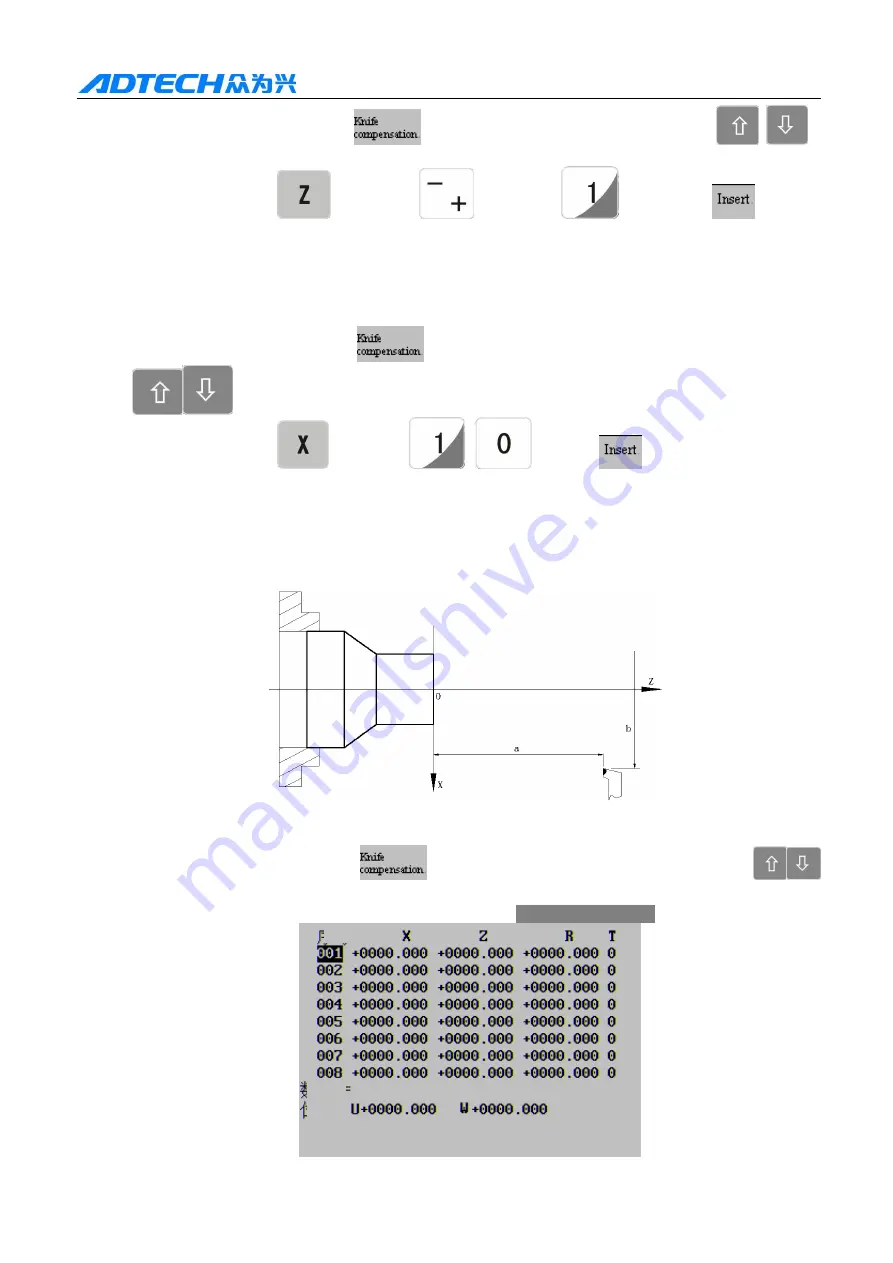

15) Press the knife compensation key

to enter the bias interface, and then press the

key to move the cursor and select bias number;

16) Press the address key

, symbol key

, number key

and Insert key

to set the

bias of axis Z;

17) Cut along surface B1 with the knife;

18) Take out the knife along axis Z when axis X is still, and stop the rotation of main axis;

19) Measure distance "α1" (suppose α1=10

)

;

20) Press the Knife compensation key

to enter the bias interface, and then press the

key to move cursor and select the bias number;

21) Press the address key

, number key

,

and Insert

key to set the bias of axis X;

22) Move the knife to safe position;

23) Repeat step 14-22 to align other knives.

Note 1: the machine tool should have mechanical origin switch to perform the knife alignment

operation in mechanical origin.

Note 2: after knife alignment in mechanical origin, it is not possible to execute the G50

instruction to set the coordinates of the work piece

As shown below:

7.4.

Editing the bias value

Press the Knife compensation key

to enter the bias interface, and then press the

key to display bias 001~016

Knife compensation parameters

Fixed knife alignment

S/N

Data

Position: