C N C 4 2 2 0 M a c hi ne Too l Op e ra t ion an d Te st

46

3-9-1

B. Press the

or

key to select the program origin of axis X or Z;

Note 1: the axis X and axis Z can’t return to program origin at the same time;

Note 2: after the program origin operation, the system cancels the knife length compensation.

9.2.

Mechanical origin

The machine tool coordinates are the reference for the machine tool to calculate coordinates,

which are the inherent coordinates of the machine tool. The origin of the machine tool coordinates is

the mechanical origin (or mechanical reference point), which is determined by the origin switch on

the machine tool. Generally, the origin switch is installed at the position of maximum travel in the

positive direction of axis X and axis Z (the origin direction can be set by relating system parameters)

9.2.1

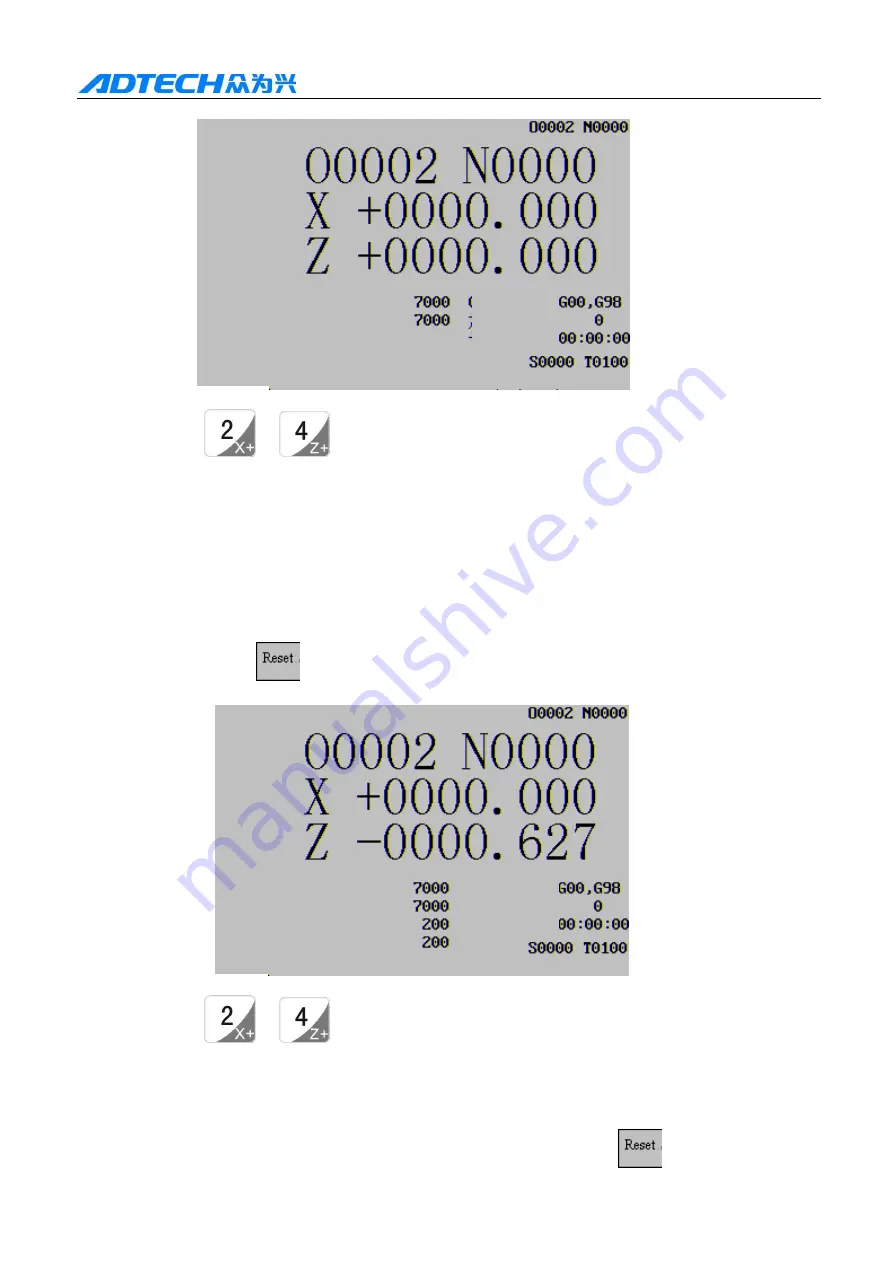

PROCEDURES OF MECHANICAL ORIGIN

A. Press the Origin

key to switch to mechanical origin mode, and the “Mechanical origin”

text appears in the bottom line of the page, as in the figure below:

B. Press the

or

key to select the mechanical origin of axis X or Z;

C. The machine tool moves in mechanical origin direction, returns to mechanical origin after

signal test, and then the axis stops moving.

Note 1: If the machine tool doesn’t have mechanical origin, do not perform the mechanical origin.

To stop the axis motion in the origin process, press the Reset key

or emergency stop

button.

Current position (absolute coordinates)

Axis X fast origin speed: G code;

Axis Z fast origin speed: Processing pieces:

Cutting time:

Program origin

Current position (absolute coordinates)

Axis X fast origin speed: G code;

Axis Z fast origin speed: Processing pieces:

Axis X slow origin speed: Cutting time:

Axis Z slow origin speed:

Mechanical origin